Method for preparing theabrownin

A technology of theabrownin and water layer, applied in the field of preparing theabrownin, can solve the problems of consuming Pu'er tea and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

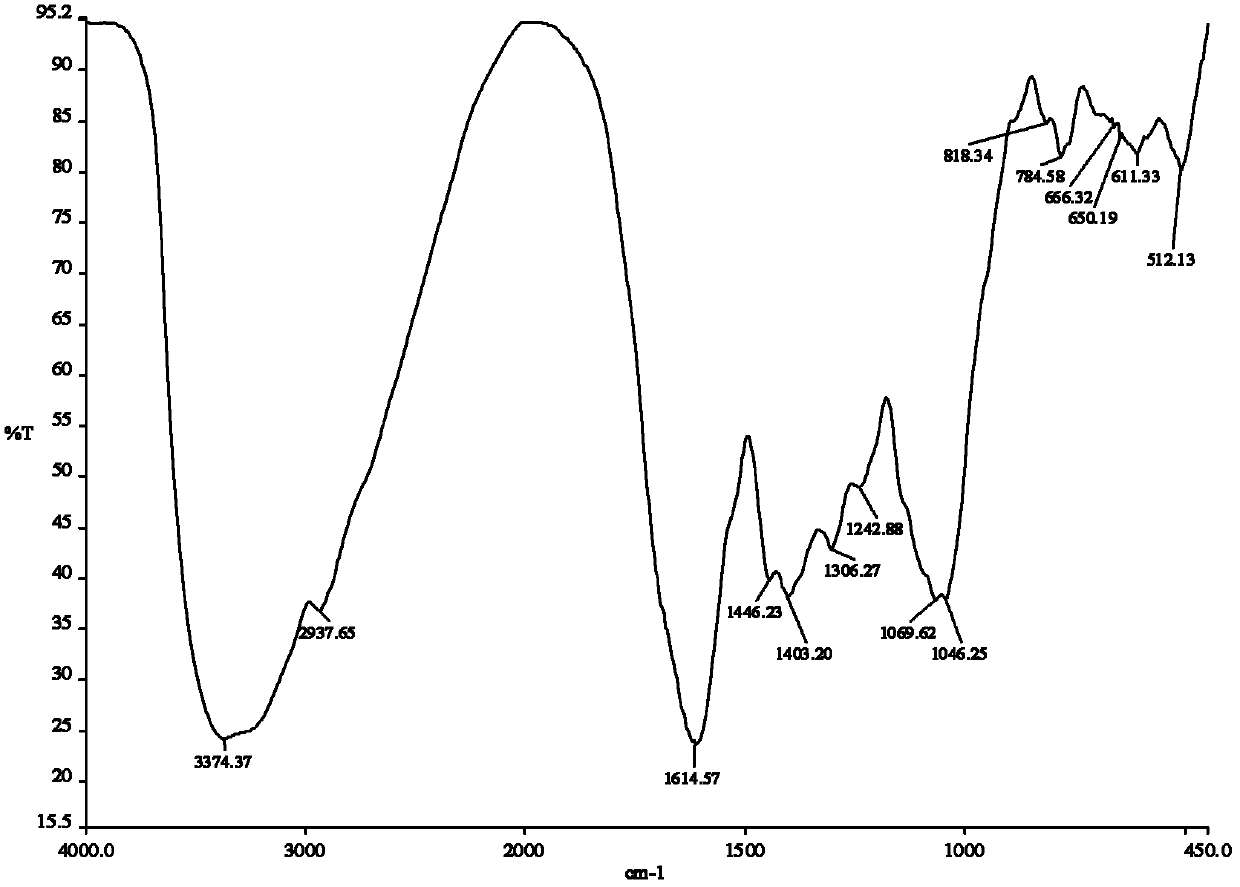

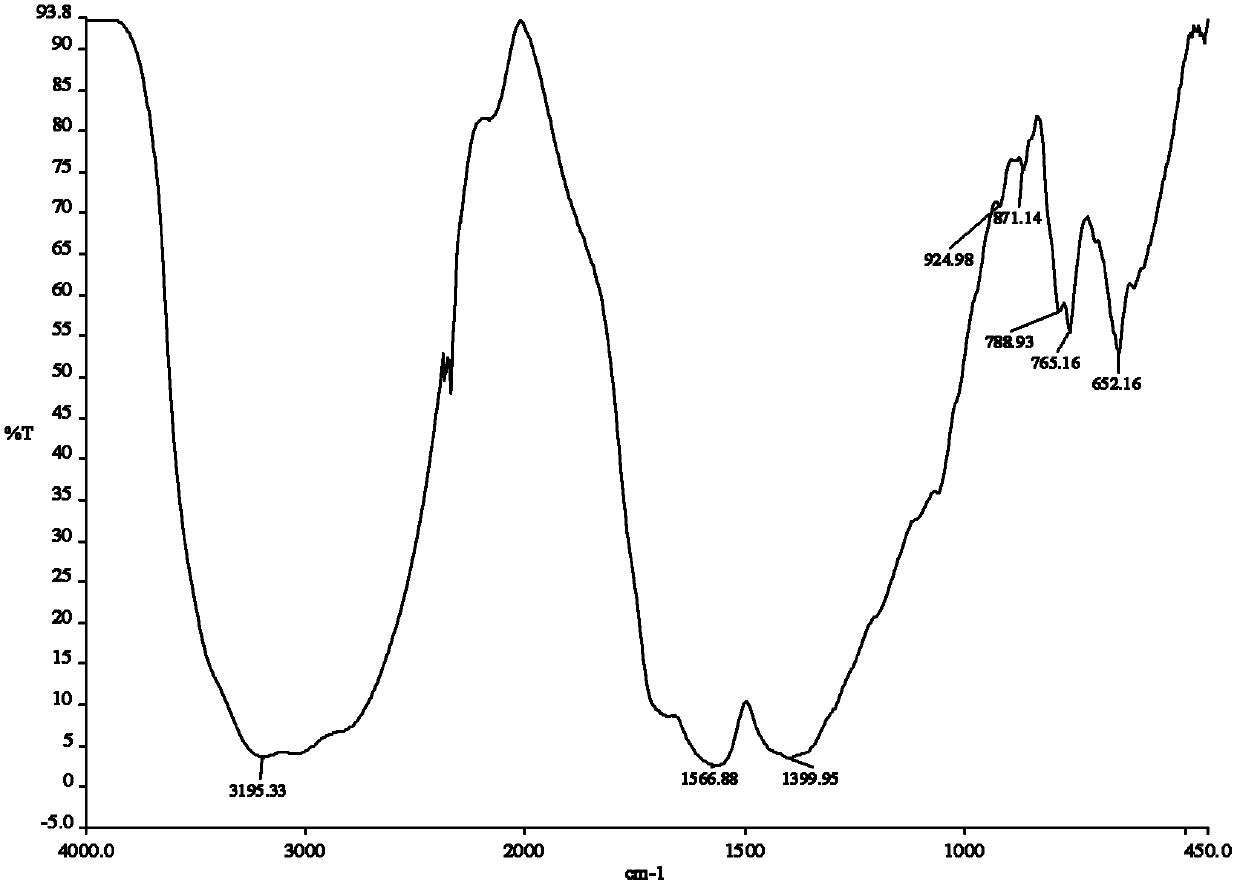

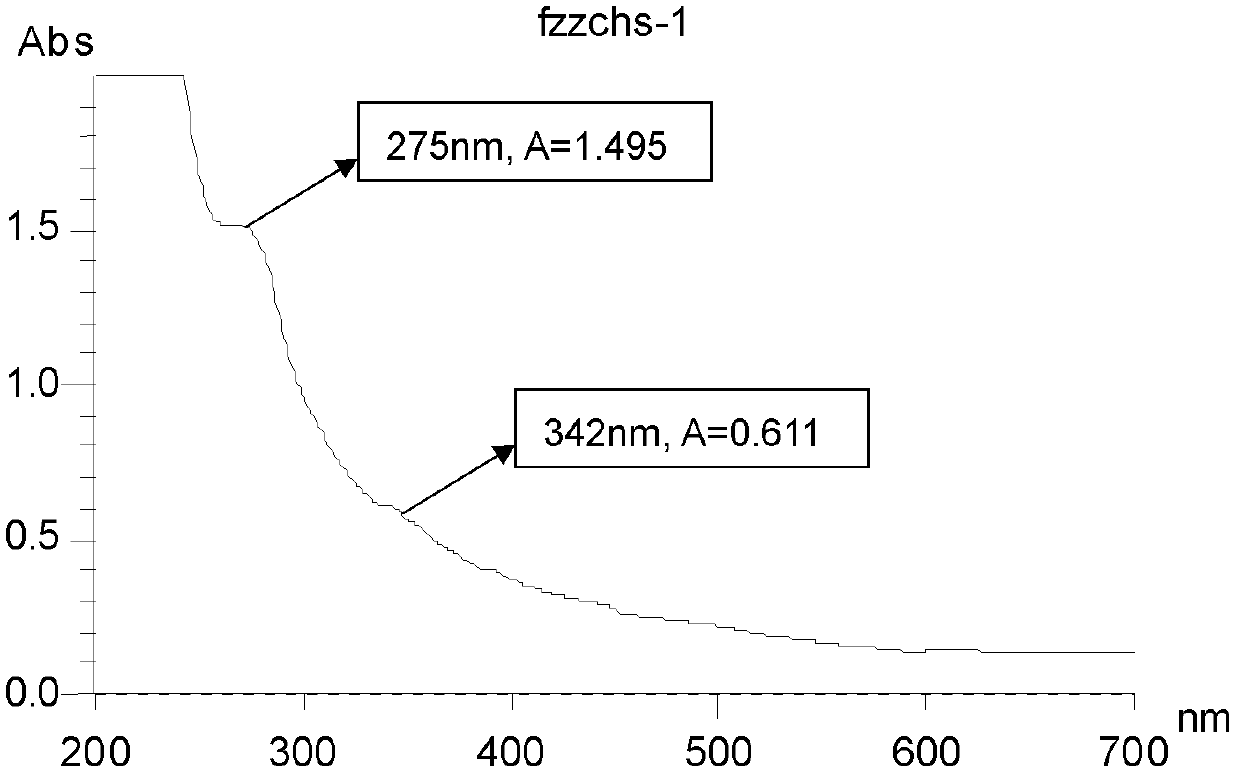

[0070] Accurately weigh 422mg of gallic acid, place it in a 250ml round bottom flask, add 100ml of water and 0.5ml of ammonia water, stir at room temperature for 48h, and obtain a crude theabrownin solution. The solution was transferred to a 250ml separatory funnel, extracted twice with ethyl acetate, the water phase was extracted twice with an equal volume of n-butanol, and the water phase was dried under reduced pressure to obtain 402 mg of homemade theabrownin.

Embodiment 2

[0072] Accurately weigh 200 mg of gallic acid, place it in a 250 ml round bottom flask, add 40 ml of water and 0.3 ml of ammonia water, stir at room temperature for 24 hours, and obtain a crude theabrownin solution. The solution was transferred to a 250ml separatory funnel, extracted once with ethyl acetate, the water phase was extracted once with an equal volume of n-butanol, and the water phase was dried under reduced pressure to obtain 200 mg of homemade theabrownin.

Embodiment 3

[0074] Accurately weigh 600mg of gallic acid, place it in a 250ml round bottom flask, add 600ml of water and 0.6ml of ammonia water, stir at room temperature for 48h, and obtain a crude theabrownin solution. The solution was transferred to a 250ml separatory funnel, extracted three times with ethyl acetate, the water phase was extracted three times with an equal volume of n-butanol, and the water phase was dried under reduced pressure to obtain 600 mg of homemade theabrownin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com