Regenerated rubber production method

A production method and rubber technology, which is applied in the field of environmentally friendly and efficient regenerated and reduced rubber production, can solve the problems of difficult wastewater treatment, destruction of cross-linking bonds, and environmental pollution, so as to reduce damage, improve compatibility, and realize recycling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

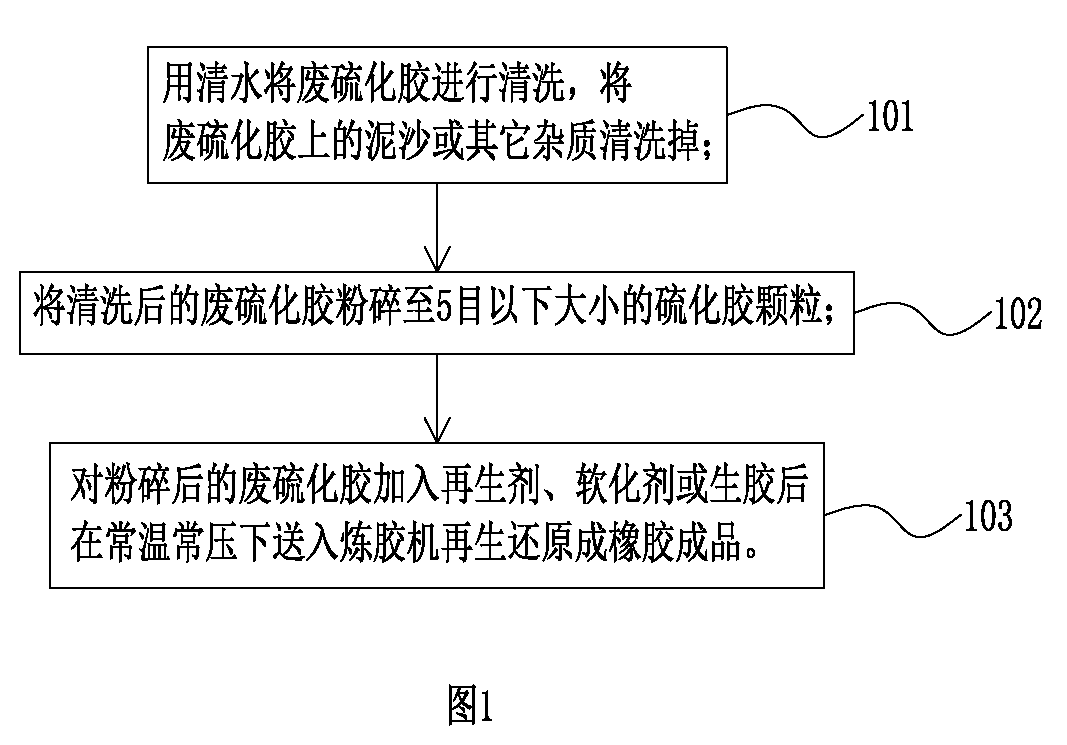

[0017] Please refer to figure 1 Shown is a flow chart of the production method for regenerated and reduced rubber of the present invention. The invention provides a production method of regenerated and reduced rubber, which uses the substitution reaction of chemical substances to break the cross-linking bonds between rubber molecules without damaging the rubber macromolecules, and because it is produced at normal temperature, the destructive effect of oxygen on rubber is greatly reduced. The method of cross-linking bonds restores the plasticity of rubber, and at the same time improves the compatibility with raw rubber to become a kind of compound rubber. Rubber recycling.

[0018] Wherein, the regenerated reduction rubber production method mainly includes the following steps:

[0019] Step 101: Wash the waste vulcanized rubber with clean water to remove the sediment or other impurities on the waste vulcanized rubber. The waste vulcanized rubber can be recycled bicycle tires,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com