Coal mine underground drilling filling reinforcement material

A technology for strengthening materials and coal mines, which is applied to the composition of drilling holes, chemical instruments and methods, etc., can solve the problems of large amount of materials used, uneven stress distribution of coal seams, reducing the strength of coal bodies around the drilling holes, etc., so as to reduce the use of cost and transportation cost, improving physical and mechanical properties, and reducing the difficulty of coal roadway support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

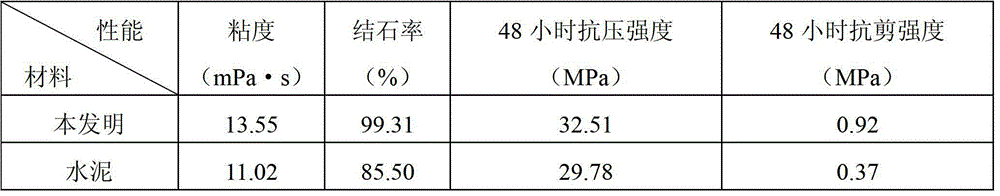

[0018] Example 1: 35% of water, 30% of ordinary Portland cement, 25% of rock powder, 8% of bentonite, 1.2% of high-efficiency air-entraining water reducer, 0.3% of sodium tripolyphosphate, and 0.5% of iron powder;

[0019] The above-mentioned substances can be used after being mixed according to the mass percentage. The stone rate of the drilling filling reinforcement material obtained by mixing is 98.5%, the compressive strength is 31.22MPa, and the shearing strength is 0.78MPa. The material has high compressive strength, strong cohesiveness and good durability, and can be better used in the filling and reinforcement of coal mine drilling.

Embodiment 2

[0020] Example 2: 40% water, 20% ordinary Portland cement, 31.6% rock powder, 6% bentonite, 1.6% high-efficiency air-entraining water reducer, 0.4% sodium tripolyphosphate, and 0.4% iron powder;

[0021] The above-mentioned substances can be used after being mixed according to the mass percentage. The stone rate of the drilling filling reinforcement material obtained by mixing is 99.1%, the compressive strength is 30.81MPa, and the shearing strength is 1.10MPa. The material has high compressive strength, strong cohesiveness and good durability, and can be better used in the filling and reinforcement of coal mine drilling.

Embodiment 3

[0022] Example 3: 30% water, 35% ordinary Portland cement, 28.5% rock powder, 4% bentonite, 1.5% high-efficiency air-entraining water reducer, 0.4% sodium tripolyphosphate, and 0.6% iron powder;

[0023] The above materials can be used after being mixed according to the mass percentage. The stone rate of the drilling filling reinforcement material obtained by mixing is 98.8%, the compressive strength is 28.95MPa, and the shearing strength is 1.44MPa. The material has high compressive strength, strong cohesiveness and good durability, and can be better used in the filling and reinforcement of coal mine drilling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com