MOCVD (Metal Organic Chemical Vapor Deposition) equipment and heating device thereof

A heating device and equipment technology, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problem of different film deposition rates, uneven thickness of organic metal film layers, and uneven overall temperature of the substrate tray 300 And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

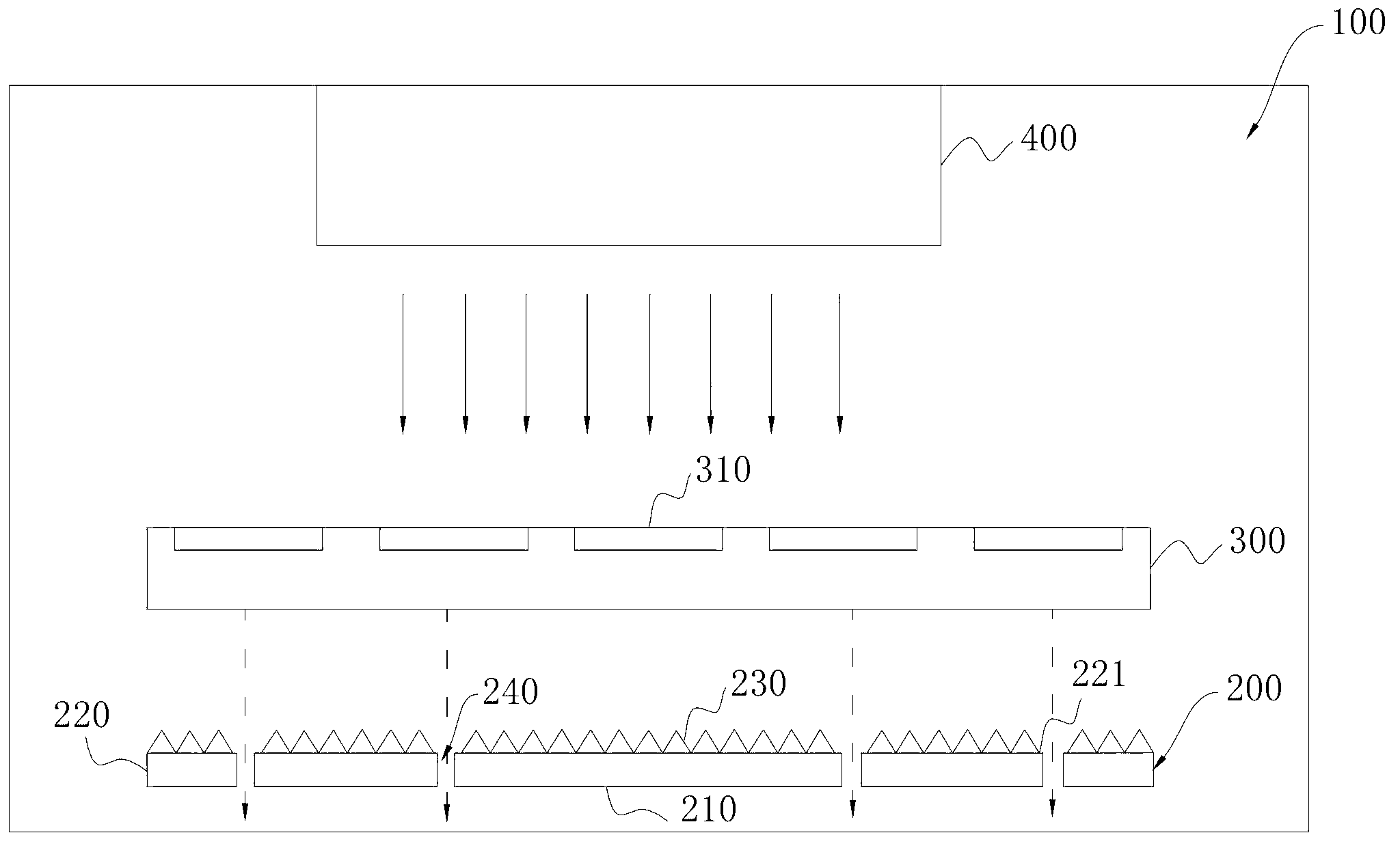

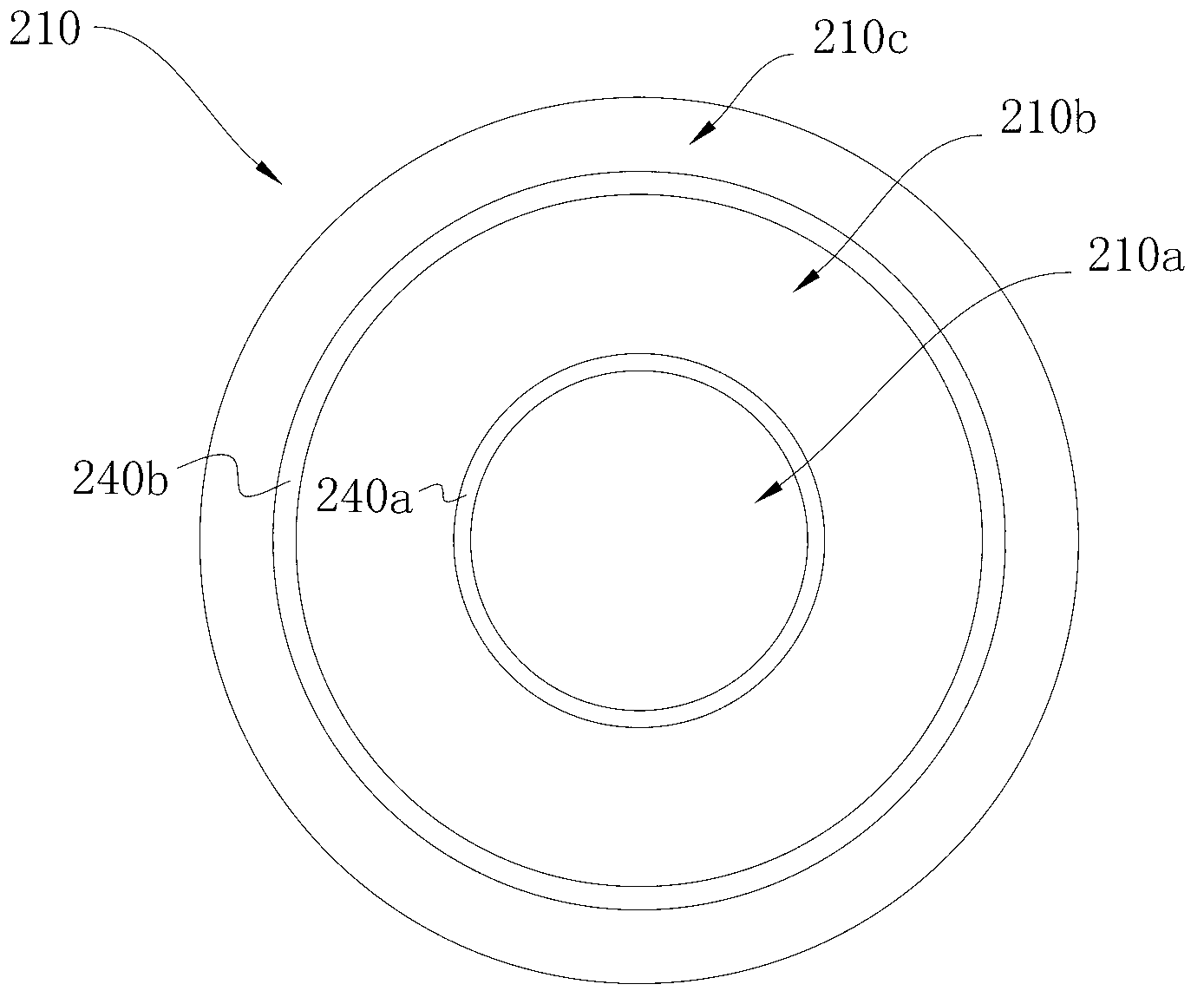

[0026] The invention provides a MOCVD equipment, including a heating device, the improvement mainly lies in preventing the heat from dissipating from the gaps between the heating zones. Specifically, see image 3 , the MOCVD apparatus of this embodiment includes a reaction chamber 100 , a heating device 200 , a substrate tray 300 and a shower head 400 . The shower head 400 is used as an air intake device for MOCVD reaction, and the shower head 400 is arranged above the substrate tray 300 for carrying the substrate, and is used for supplying reaction gas to the substrate 310 placed on the substrate tray 300 . The heating device 200 is arranged under the substrate tray 300, and is used to heat the substrate tray 300, and then correspondingly heat the substrates 310 arranged on the substrate tray 300, decompose the reaction gas, and generate Form a thin film. The heating device 200 includes at least two mutually spaced heating zones 210 , each heating zone 210 includes a chassi...

Embodiment 2

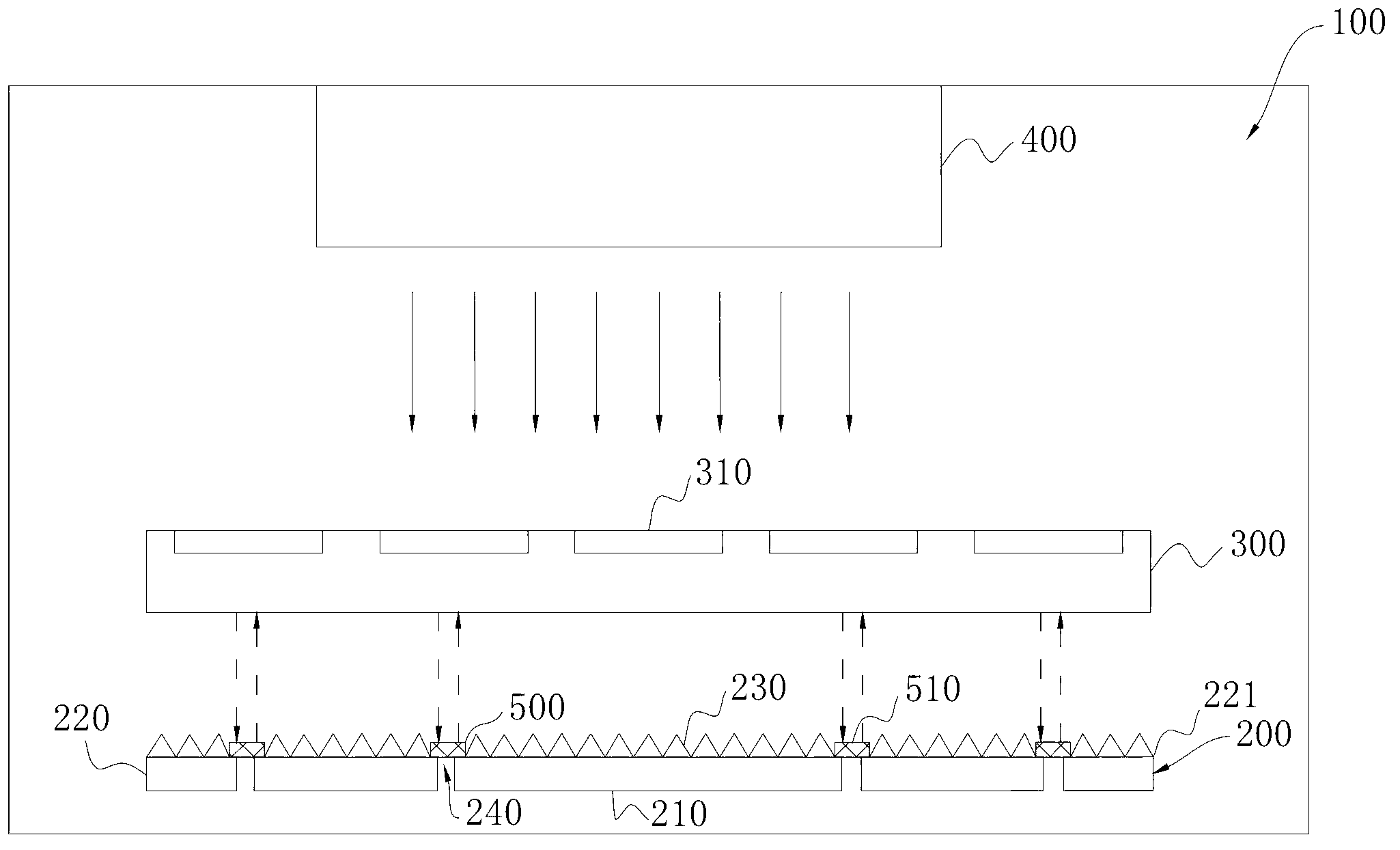

[0033] Different from Example 1, as Figure 5 and Figure 6 As shown, the heat insulation board 500 is nested in the gap 240 between adjacent heating zones 210, and the heat insulation board 500 preferably fills up the gap. Compared with Embodiment 1, the flatness of the plane where the heating surface 221 is located is better. In this embodiment, the heat shield 500 is made of high-temperature ceramic materials. Ceramics also have high-temperature refractoriness and heat insulation, and the thermal conductivity of ceramics is the lowest among all refractory materials, so the reduction of heat shields can also be achieved. The heat transfer loss of 500 is to ensure that the substrate tray 300 is evenly heated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com