Device for preparing nanofibers by differential split-flow centrifugal spinning method

A centrifugal spinning and nanofiber technology, applied in fiber processing, textiles and papermaking, filament/thread forming, etc., can solve problems such as energy consumption and safety, uneven fiber thickness, and increased rotation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

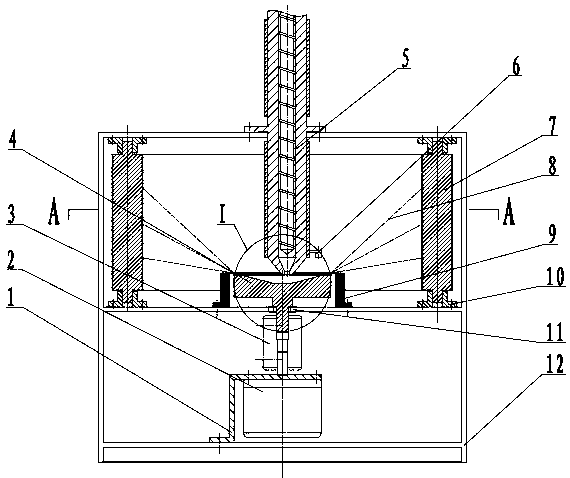

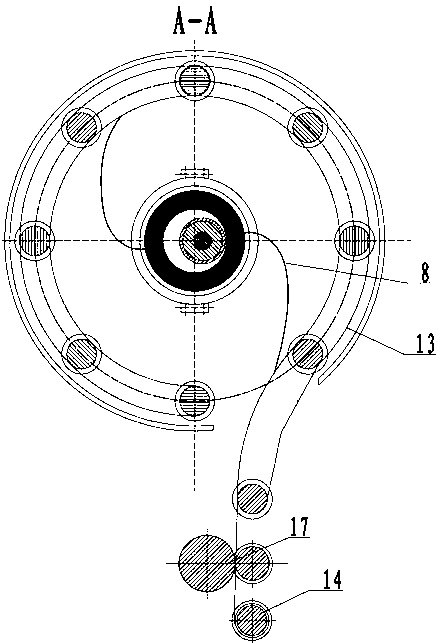

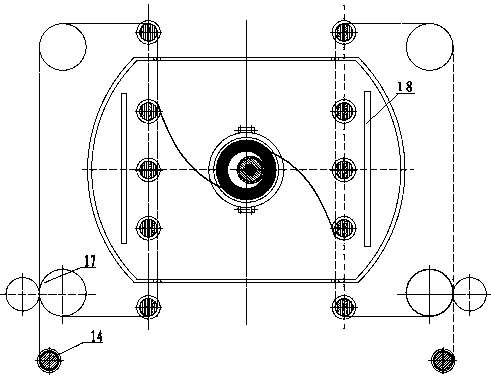

[0023] A kind of device of the present invention prepares nanofiber by differential flow centrifugal spinning method, such as figure 1As shown, it mainly includes motor bracket 1, high-speed motor 2, coupling 3, rotating body 4, continuous feeding device 5, infrared temperature sensor 6, conveyor belt roller group 7, electromagnetic heater 9, roller bearing housing 10, rotating Body bearing 11, spinning box 12, transport cord 13, rolling device 17, winding device 14, wherein the motor bracket 1 is fixed on the lower part of the spinning box 12 to fix the high-speed motor 2, and the high-speed motor 2 passes through the coupling 3 and the rotating body bearing 11 drive the rotating body 3 to rotate at high speed, the continuous feeding device 5 is fixed on the top of the spinning box 12, the discharge port is placed on the upper end of the rotating body 4 in an eccentric manner and keeps a small distance, and the infrared temperature sensor 6 is fixed Connected to the continuou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com