Hydraulic Wax Removal Device for Rodless Pump Oil Production System

A technology of oil production system and rodless pump, which is applied in the direction of cleaning equipment, earthwork drilling, wellbore/well parts, etc. It can solve the problems of accelerated wax deposition in polymer flooding electric pump wells, increased labor intensity of workers, and limited weight of weighted rods, etc. problem, achieve the effect of promoting the progress of oil and gas field development technology, the outer diameter of wax removal is flexible and variable, and the labor intensity is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further explained below in conjunction with the drawings:

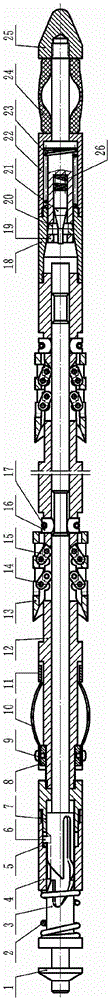

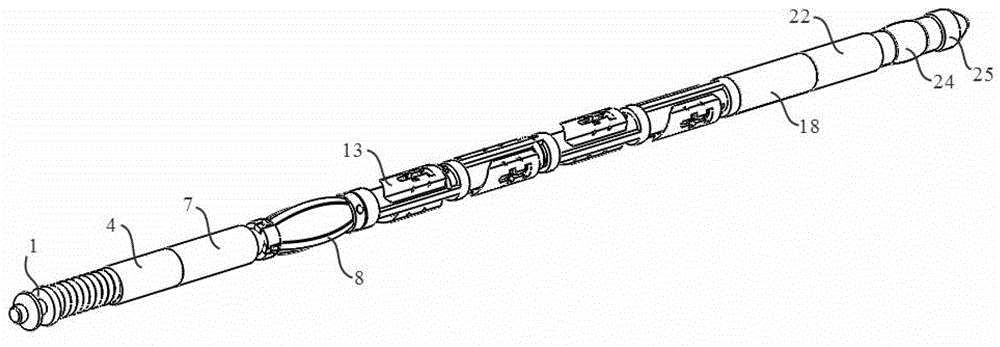

[0020] by figure 1 As shown, the hydraulic wax removal device of the rodless pump oil recovery system is divided into an inner and an outer two-layer structure. The outer layer is an outer sleeve unit, a scraper unit and a centralizing unit, and the inner layer is a central rod unit.

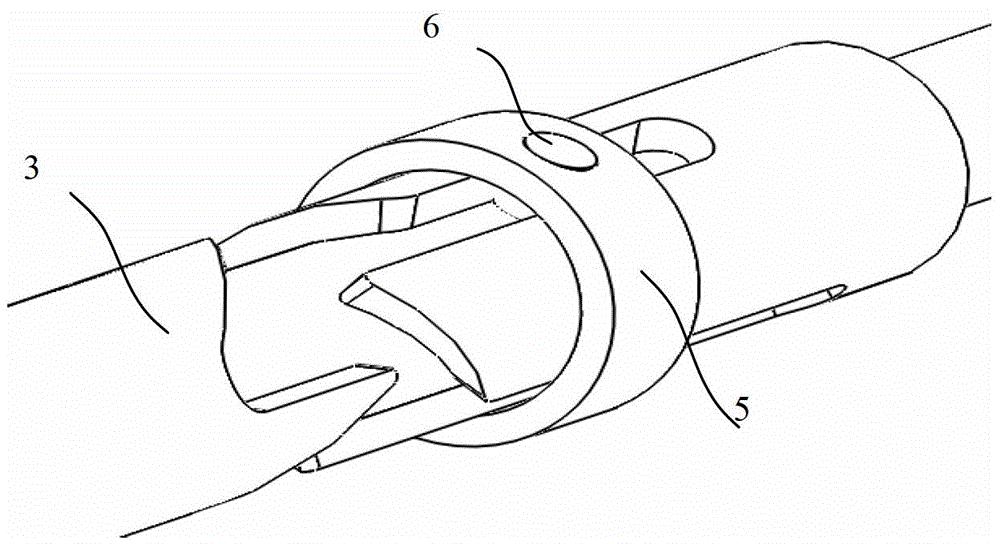

[0021] Wherein, the outer sleeve unit is formed by connecting No. 1 outer sleeve 4, No. 2 outer sleeve 7, No. 3 outer sleeve 12, inner cone sleeve 18, and No. 4 outer sleeve 22. A slip ring 5 is fixed between the outer sleeves 7. The structure diagram of the slip ring is as follows image 3 As shown, after being fixed, the slip ring 5 can rotate relative to the outer sleeve unit, but its axial direction does not move relative to the outer sleeve unit; the slip ring 5 is provided with a pin hole and a slip ring pin 6 is built in.

[0022] The scraper unit is as figure 1 , figure 2 , Figure 5 , Image 6 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com