In-situ gas turbine rotor blade and casing clearance control method and system

A technology for gas turbines and rotor blades, used in liquid fuel engines, components of pumping devices for elastic fluids, mechanical equipment, etc., to solve problems such as damage, weakening of the distal end of the blade tip, cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

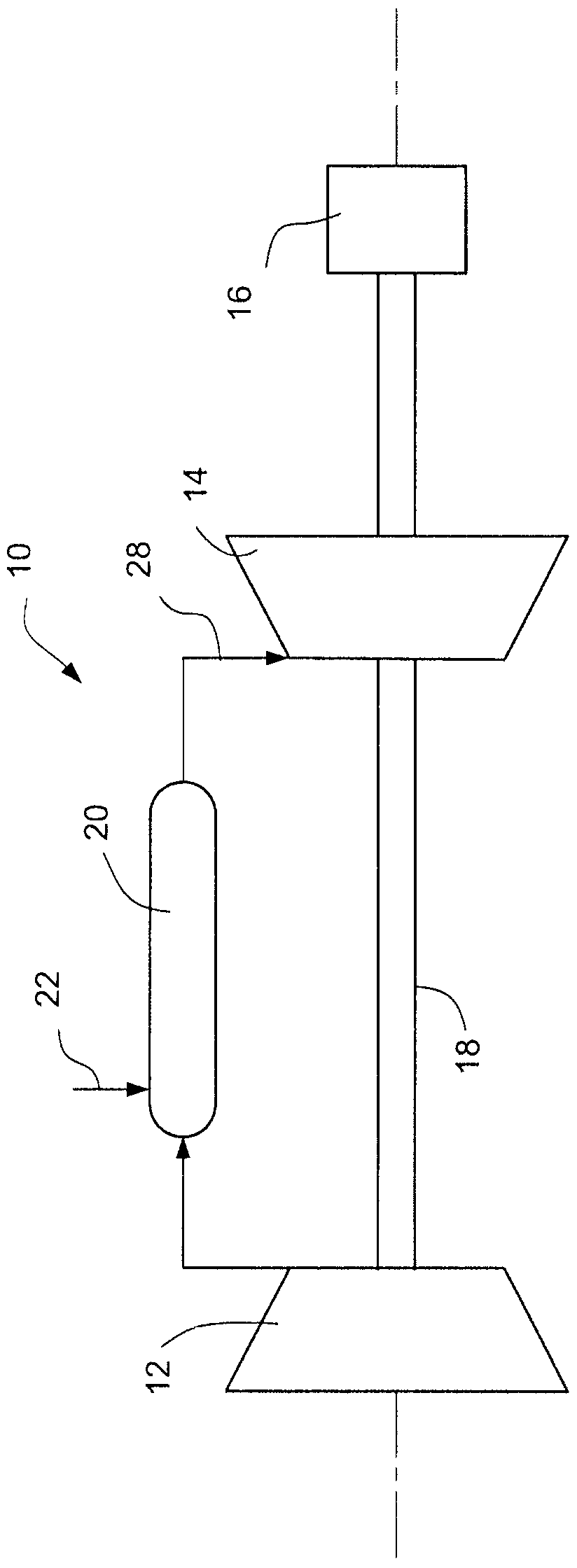

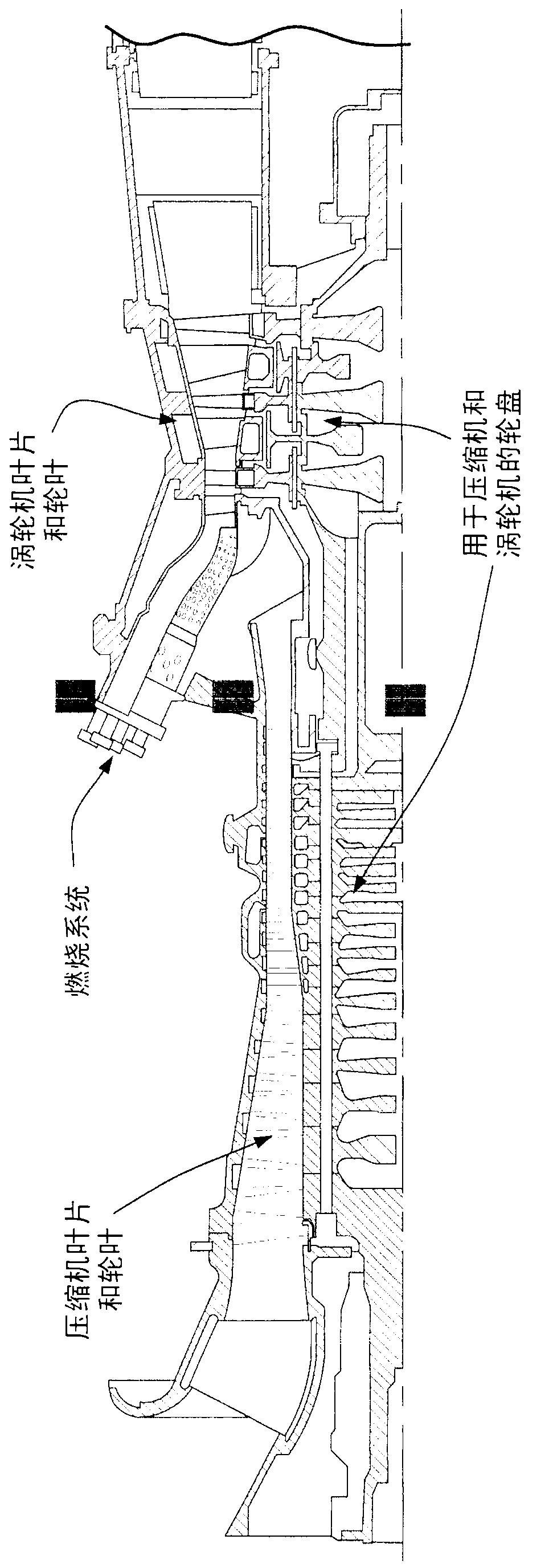

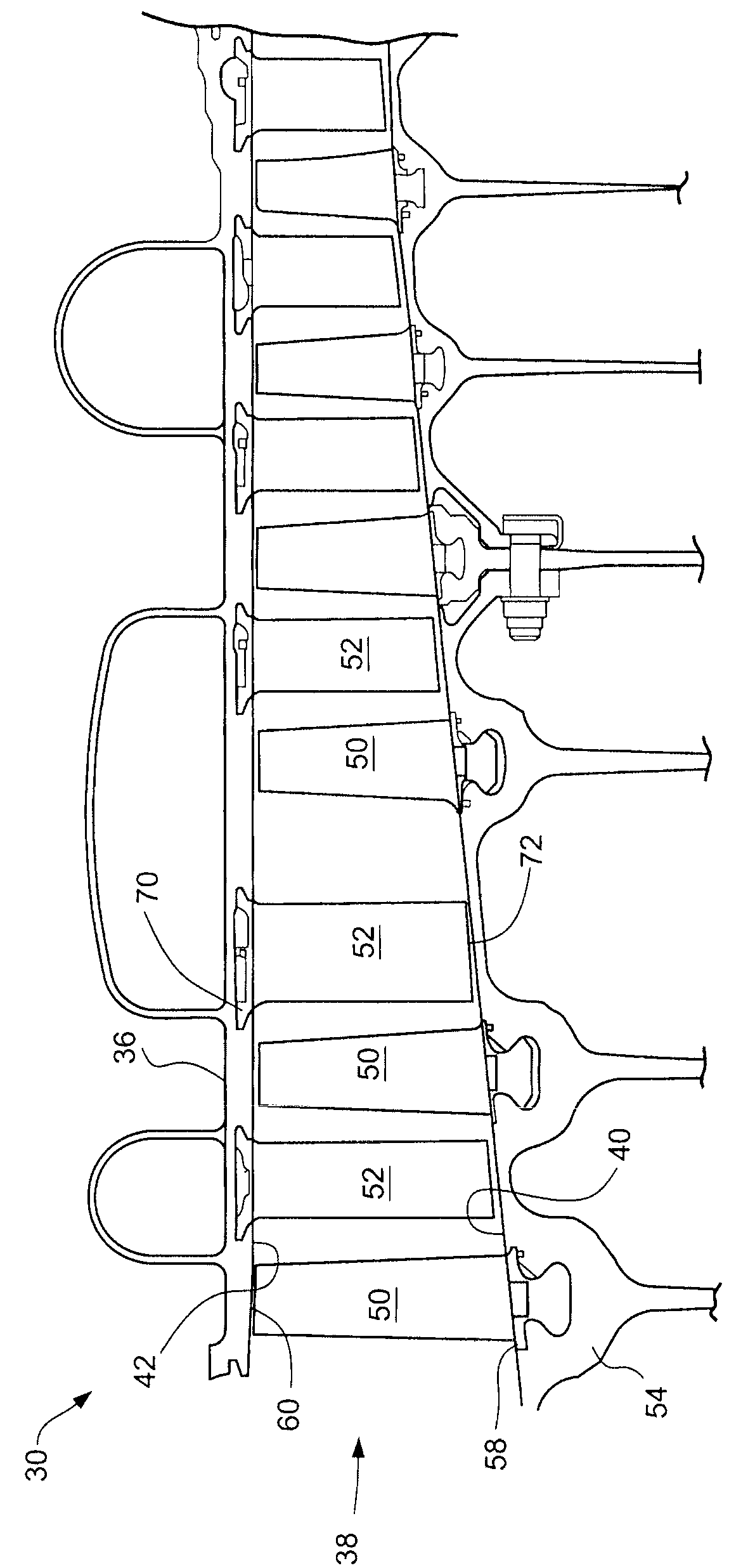

[0011] As mentioned above, the coating method according to the invention can be implemented on a variety of rotating assemblies, in particular compressors comprising a rotor rotating around a central longitudinal axis, and a rotor mounted to the disc and extending radially outwards. Multiple leaves. Most rotor assemblies also include a housing that is generally cylindrical in shape and has an inner peripheral surface spaced radially outward from the rotor and blades such that the inner peripheral surface of the housing meets the ends of the rotor blades A narrow annular space is formed between the blade tips.

[0012] The abradable coating according to the present invention is applied to a selected portion of the inner circumference of the casing in an amount sufficient to define a minimum annular gap after abrasion, as defined by the inner circumference of the casing and the tips of the rotating blades. As the rotor grows differentially (for example, because heat is conducte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com