Real-time heat flow detection device and real-time heat flow detection method thereof

A real-time detection and heat flow technology, applied in the direction of measuring devices, electric devices, calorimeters, etc., can solve the problem that the thermopile measurement circuit is easily affected by the surrounding alternating electromagnetic field, the thermoelectric characteristics are nonlinear, and the thermoelectric characteristics of the thermocouple cannot be guaranteed, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The invention provides a heat flow real-time detection device and a heat flow real-time detection method thereof. The present invention will be further described below in conjunction with the accompanying drawings and best implementation examples.

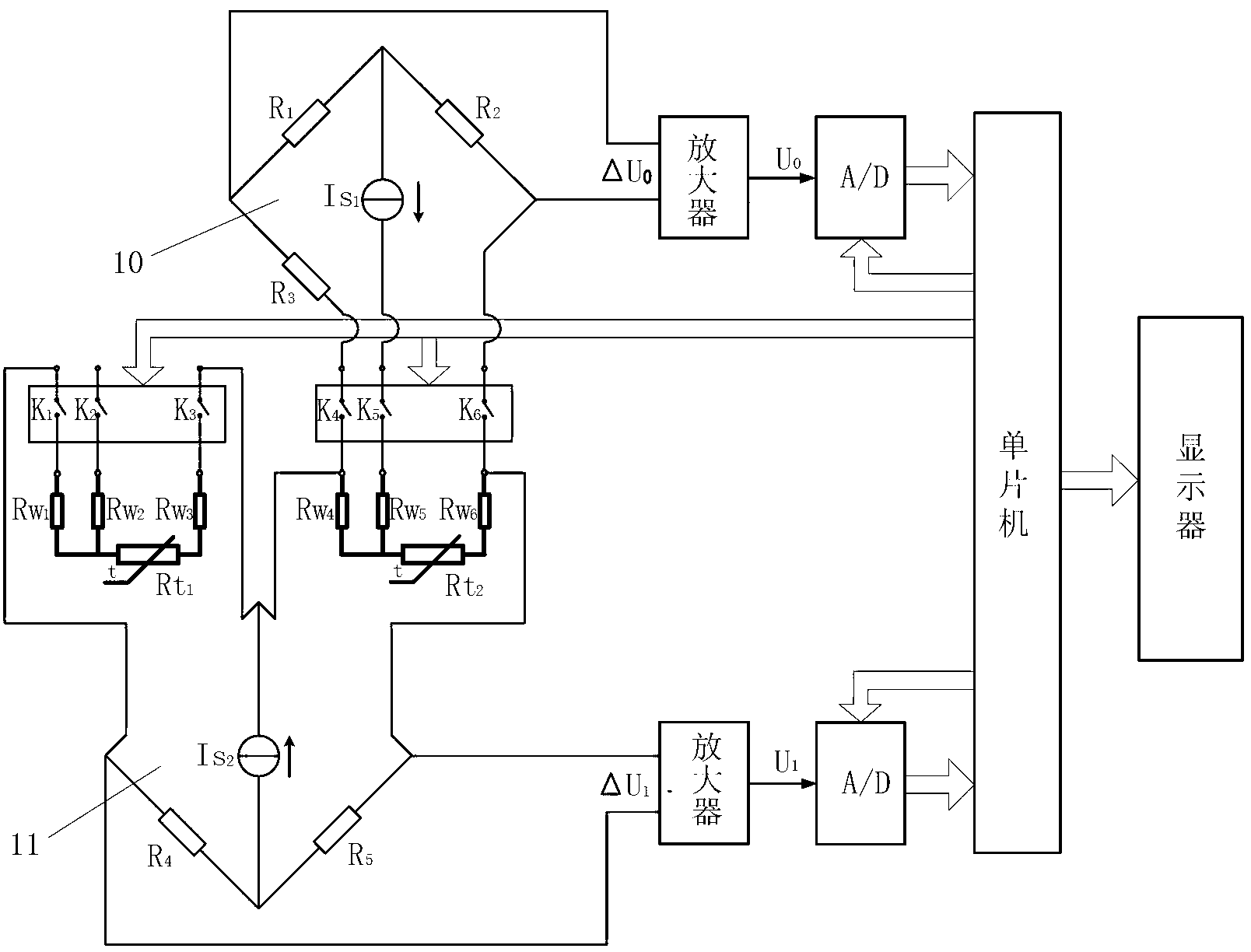

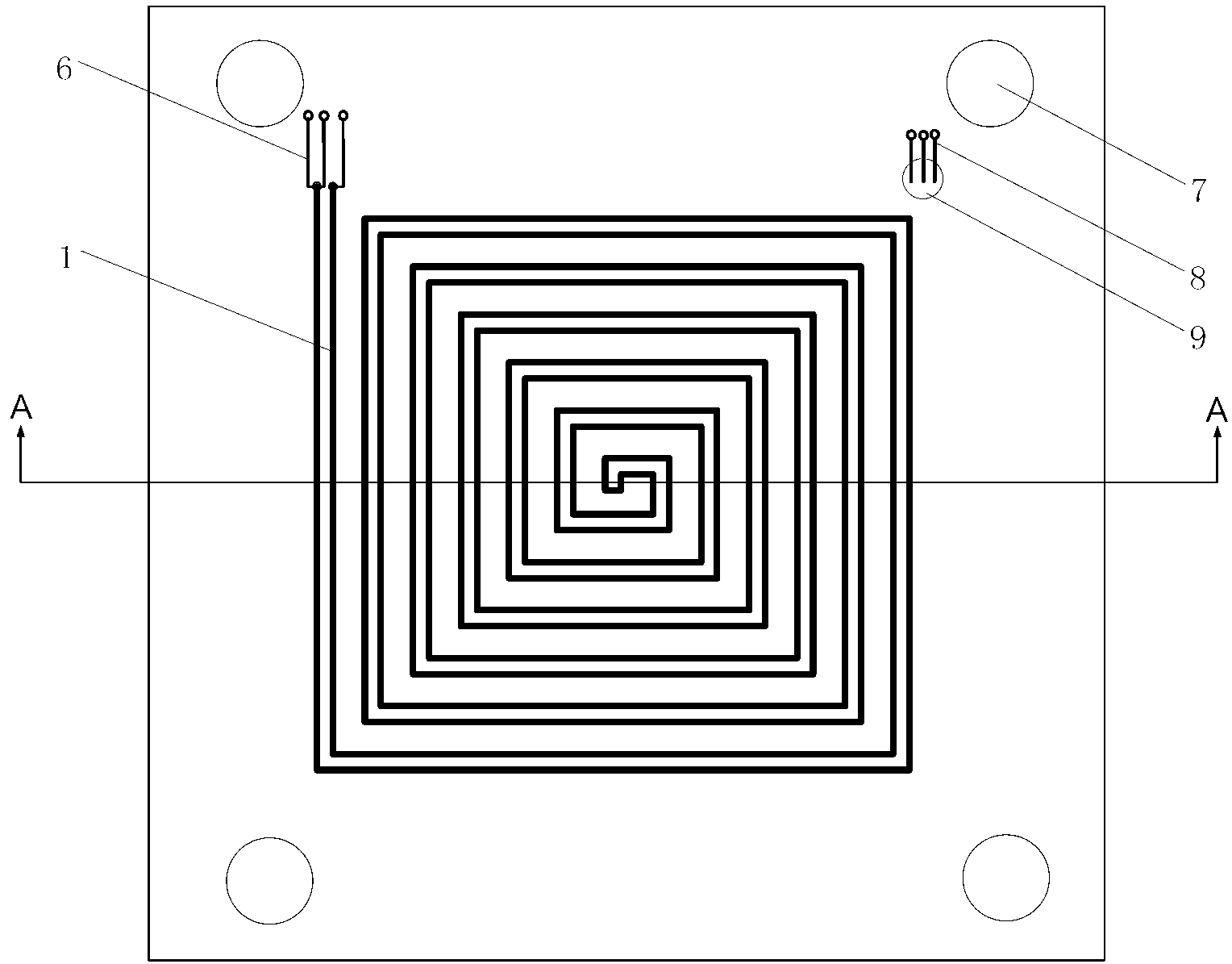

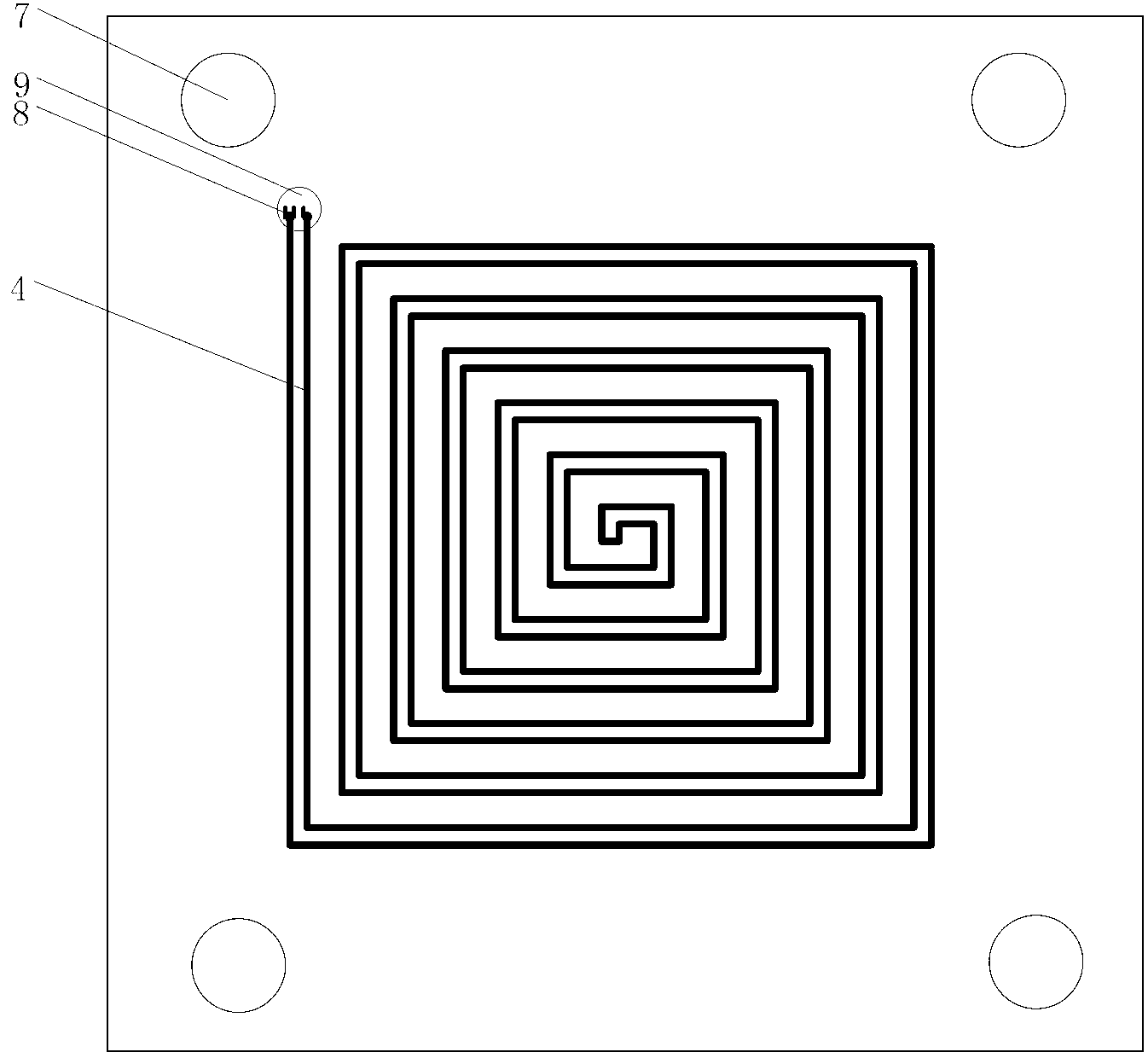

[0045] figure 1 The heat flow real-time detection device shown is composed of a thin-film non-inductive thermal resistance temperature sensor, a signal processing system and a display system. The signal processing system consists of a temperature measuring bridge 10, a difference measuring bridge 11, two amplifiers, two A / D converters, a single chip microcomputer, and a programmable control switch K 1 、K 2 、K 3 、K 4 、K 5 、K 6 Composed of, where the temperature measuring bridge 10 is composed of R 1 , R 2 , R 3 , The constant current source current Is of the temperature measuring bridge 10 1 and with programmable control switch K 4 、K 5 、K 6 Connect the thermal resistance value R of the upper end face t2 composi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com