Singlechip integrated type carbon nano tube humidity sensor based on sine wave stimulation

A humidity sensor, carbon nanotube technology, applied in the direction of material resistance, etc., to achieve the effect of small size, cost saving, and convenient signal detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

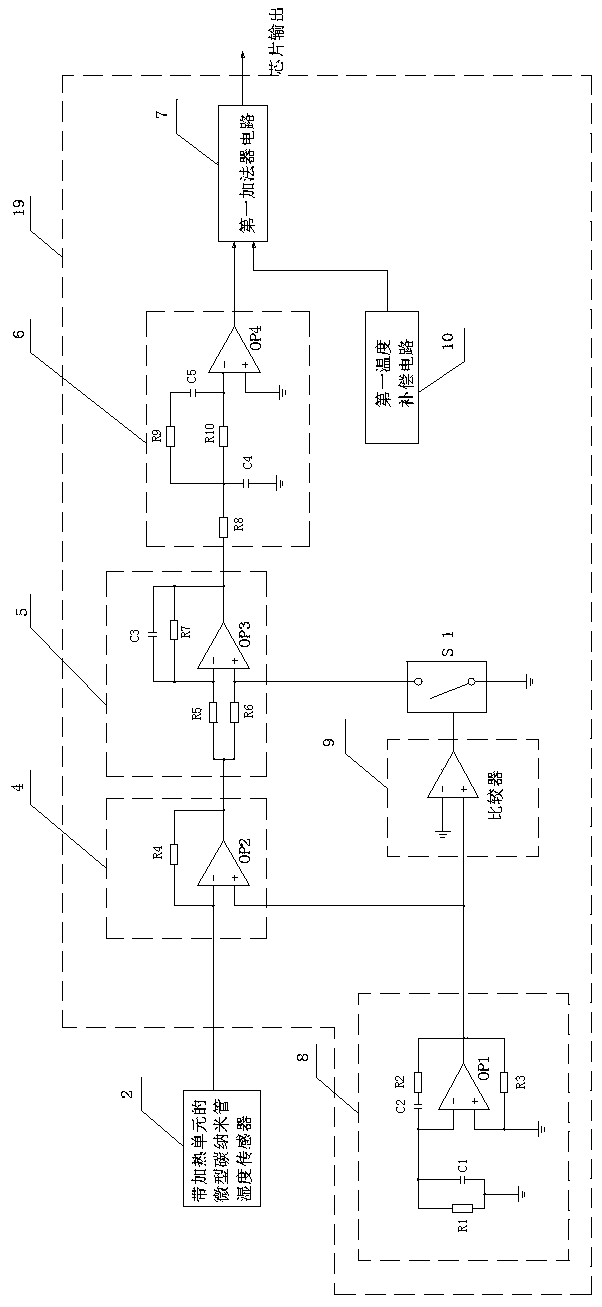

[0013] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 Explain that this embodiment includes a micro-carbon nanotube humidity sensor 2 with a heating unit and a sine wave excitation interface circuit 1;

[0014]The sine wave excitation interface circuit 1 is a detection resistance type sine wave excitation circuit 19 or a detection capacitance type sine wave excitation circuit 20; the detection resistance type sine wave excitation circuit 19 is composed of the first sine wave generating circuit 8, the first switch S1, the first preamplifier circuit 4, the first phase-sensitive demodulation circuit 5, the first low-pass filter circuit 6, the first temperature compensation circuit 10, the first comparator 9, and the first adder circuit 7; The switch S1 is a standard CMOS pair tube switch with a control terminal; the output terminals of the first sine wave generating circuit 8 are respectively connected with the first input terminal of the...

specific Embodiment approach 2

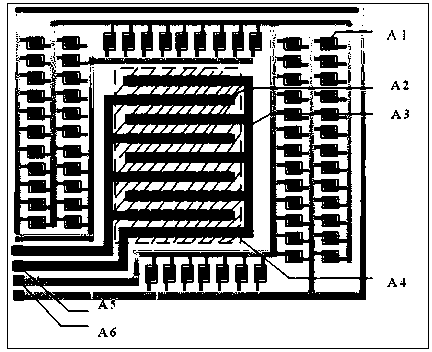

[0015] Specific implementation mode two: combination figure 1 , figure 2 Note that the difference between this embodiment and the first embodiment is that when the characteristic size of the CMOS IC process is 0.5um, the total area of the pair of interdigitated electrode layer structures is 1800um×1800um, and the pole width of the interdigitated electrodes is 90um, the distance between the two poles is in the range of 30-60um; the size of each pad window 2 is 90um×90um.

[0016] Working principle: set polysilicon resistor A1 around the carbon nanotube humidity sensitive film A4, periodically energize the heating unit formed by the parallel connection of polysilicon resistors A1, and promote the removal of water vapor and other adsorbed impurities by increasing the surface temperature of the carbon nanotube humidity sensitive film A4 Attachment: The sensor applies a sine wave signal to ensure that the entire interface circuit works normally at a frequency lower than 1MHz. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com