Mutual capacitance variation measuring circuit with high precision and low power consumption

A mutual capacitance and circuit technology, which is applied in the field of mutual capacitance measurement circuits, can solve the problems of increasing chip area and power consumption, difficulty in ensuring parameter consistency, and failure to measure the variation range, and achieves improved measurement accuracy and easy mass production control. The effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

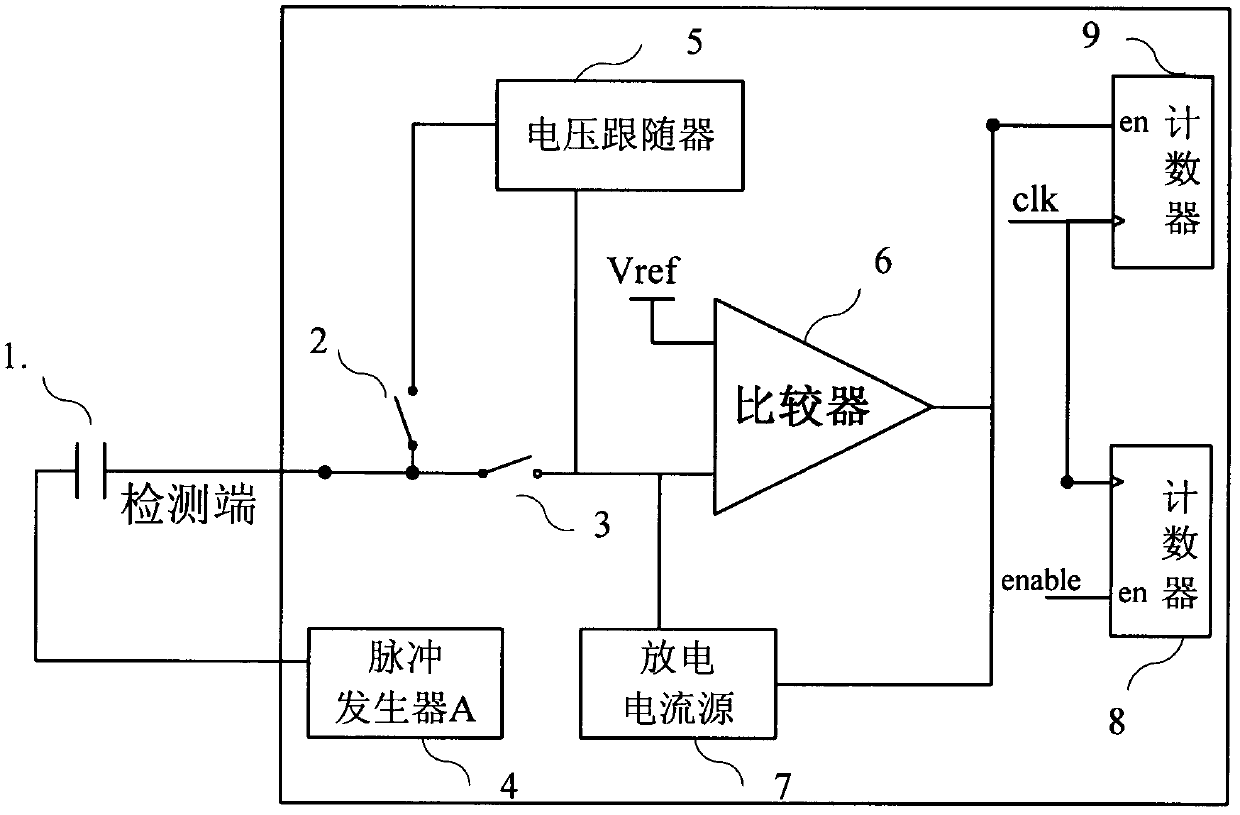

[0028] figure 1 It is the basic system circuit diagram of the measurement circuit. A measurement cycle of this measurement circuit can be divided into three steps, namely:

[0029] 1) Pulse generator clock high cycle phase

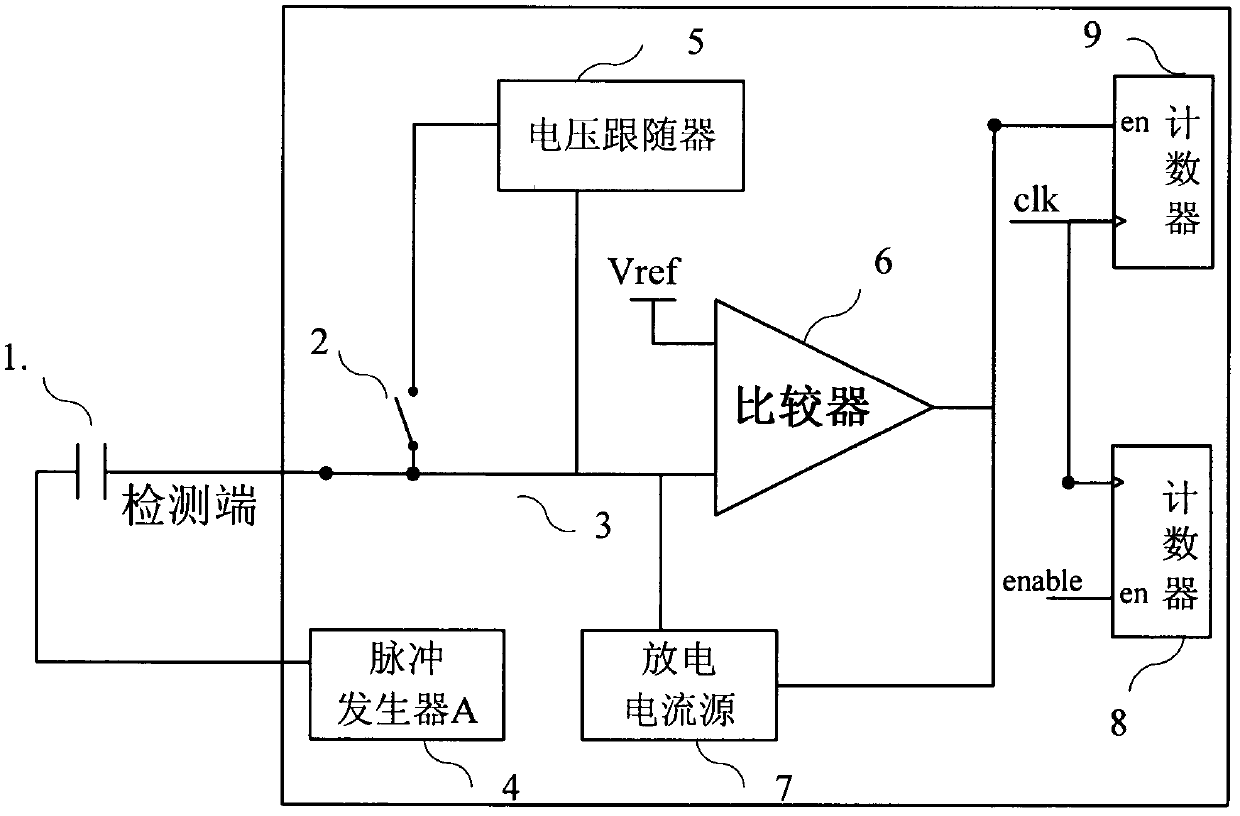

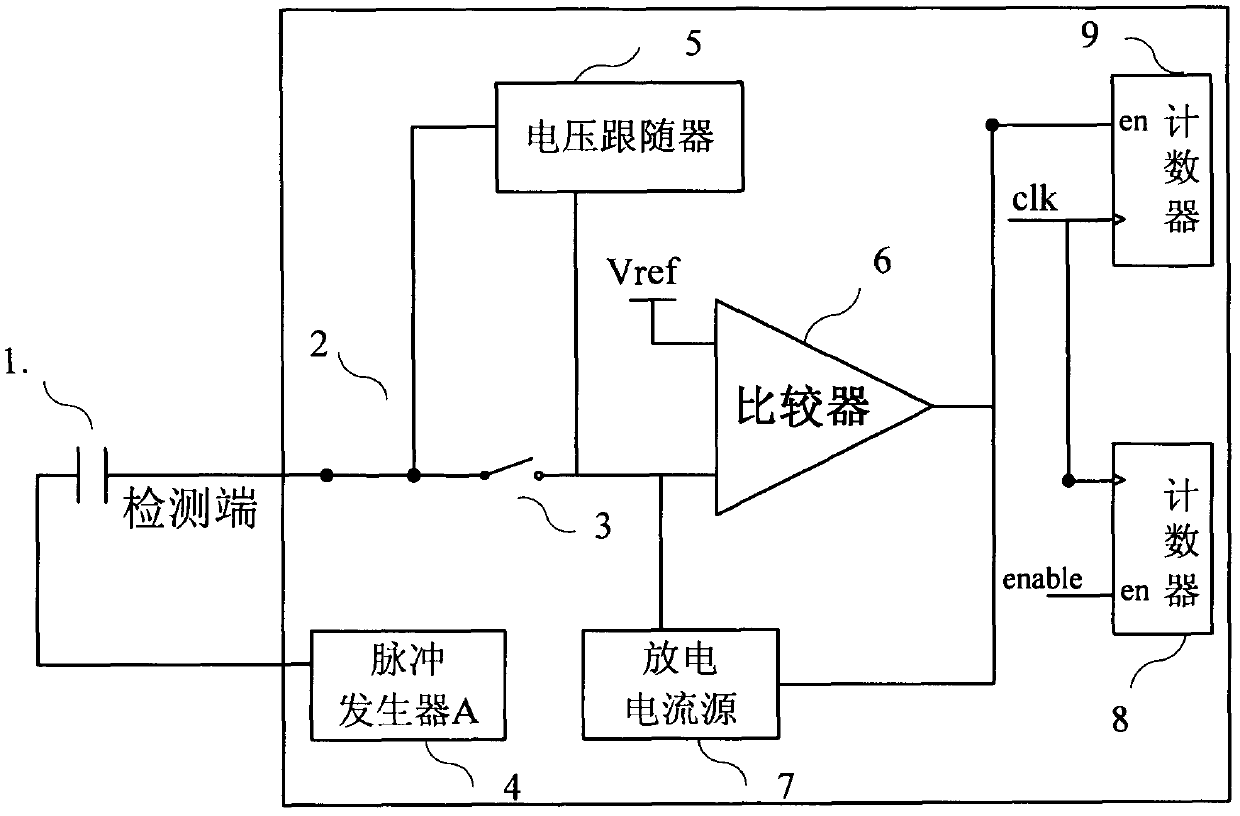

[0030] exist figure 1 , open the switch (2), close the switch (3), its equivalent circuit is as figure 2 shown. At this stage, the rising edge of the clock of the pulse generator will charge the detection terminal of the measured mutual capacitance. When the voltage exceeds Vref, the comparator will start the discharge current source to discharge it until the voltage is less than Vref. The voltage waveform at the detection terminal changes as Figure 4 The t1, t2 stages shown in.

[0031] 2) Pulse generator clock low cycle phase

[0032] exist figure 1 , open the switch (3), close the switch (2), its equivalent ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com