Integrated LED (Light Emitting Diode) light emitting device and manufacturing method thereof

A technology of light-emitting devices and manufacturing methods, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve problems such as poor connection stability, achieve better heat dissipation, increase service life, and reduce thermal resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

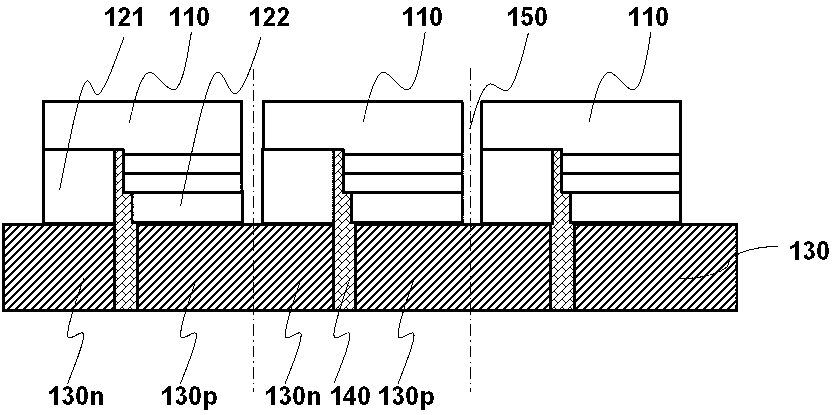

[0042] In this embodiment, in order to simplify the drawings and facilitate the description, three LED light-emitting units are taken to form an integrated LED light-emitting device. It should be understood that the present invention is not limited to this, and the number of light-emitting units can be selected according to specific implementation needs. number.

[0043] Please refer to the attached figure 1 , The integrated LED light-emitting device includes: a light-emitting epitaxial unit 110, ohmic contact layers 121, 122, an electrode pad layer 130, and an insulator 140. Specifically, each light-emitting epitaxial unit 110 is isolated from each other by the epitaxial layer through the isolation channel 150. In a preferred embodiment, the isolation channel 150 can be filled with insulating material. The light-emitting epitaxial unit 110 has a flip-chip structure, and includes an N-type epitaxial layer, a light-emitting layer, and a P-type epitaxial layer from top to bottom, b...

Embodiment 2

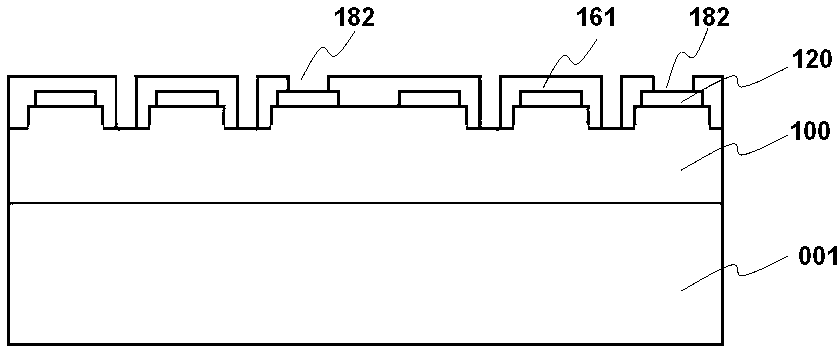

[0047] In some large-size light-emitting devices, the shape and size of the P and N regions of the electrode pad layer will become one of the important factors that affect the reliability of the device. For example, in the asymmetric electrode design of the prior art, in the eutectic process Excessive difference in the size of the electrode area may cause the chip to tilt, causing eutectic failure at the electrode with a relatively small area, and finally causing electrical connection failure.

[0048] Please refer to the attached image 3 The main difference between this embodiment and Embodiment 1 is that the areas of the P and N regions 130p and 130n of the electrode pad layer are close or substantially the same. This is specifically achieved in the following manner: an insulating layer 160 is provided on the P and N ohmic contact layers 122 and 121, and the N-type ohmic contact layer 121 is electrically insulated from the light-emitting layer of the LED epitaxial structure and...

Embodiment 3

[0050] In this embodiment, the lower surface of the end of the insulator 140 away from the light-emitting epitaxial stack protrudes from the lower surface of the electrode pad layer 130, which effectively prevents the P and N electrodes from being short-circuited in the subsequent packaging process of the device. Assuming that the height difference between the relative position of the lower surface of the electrode pad layer 130 and the relative position of the lower surface of the insulator is H, the gap D between the P and N regions of the electrode pad layer can be optimized by adjusting the sizes of H and D. The effect of implementation. In this embodiment, the height difference H may be 20-100 μm, preferably 50 μm, and the gap D may be 20-100 μm, preferably 50 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com