Method for separating liquid from suspended matter in a sludge and device for same

A technology for suspended matter and mud, applied in separation methods, chemical instruments and methods, precipitation separation, etc., can solve problems such as blockage and long time, and achieve low power consumption and cost saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

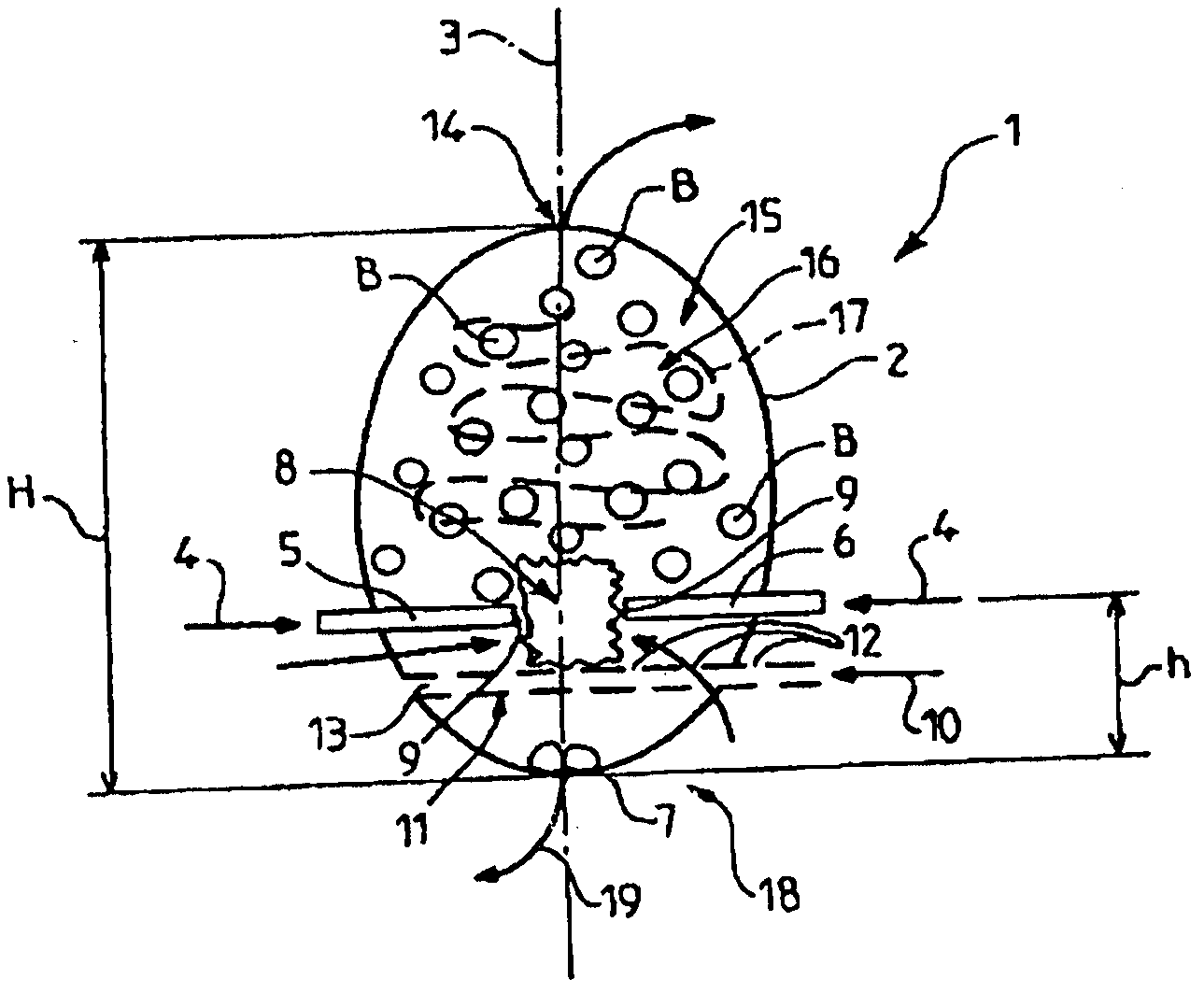

[0067] figure 1 The principles of the method of separation between liquid and solids of a slurry according to embodiments of the invention described more particularly herein are shown.

[0068] In a reactor 1 formed by an oblong shell 2 elongated around an axis 3 with a small volume v, for example about 50 liters, injection is via two opposing nozzles 5, 6 symmetrical with respect to the shell axis 3 Waste liquid (arrow 4).

[0069] These nozzles are located in the bottom part of the housing, for example at a distance h from the housing bottom 7 of between one fifth and one third of the height H of the housing.

[0070] These two nozzles positioned opposite each other allow the pressurized feed of a water stream with a high load of dry matter (MS) (eg MS 10% / τ of the total weight), which causes a strong impact of the two streams where they meet in zone 8 .

[0071] In other words, the pumping of external water (not shown) introduced into the shell of the small-scale reactor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com