Manufacturing method of individualized stent for repairing defect of more than four tooth positions on one side of low jawbone

A manufacturing method and technology for mandibles, which are used in bone implants, medical science, prostheses, etc., can solve the problems of lack of mature technology for mandibles, fast absorption, inability to provide good mechanical support, and inability to repair, etc. And the effect of guiding bone growth, good stress structure, good bone growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

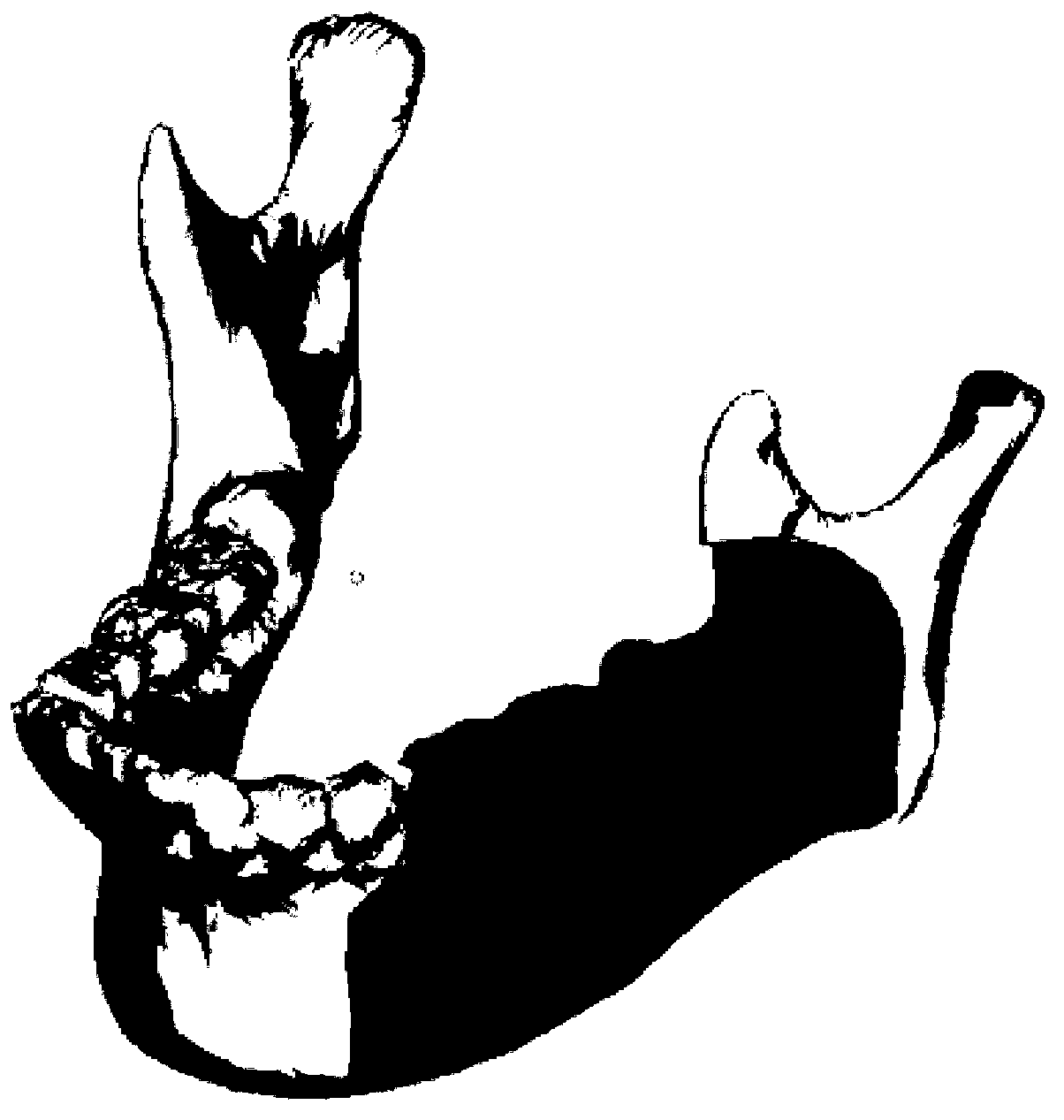

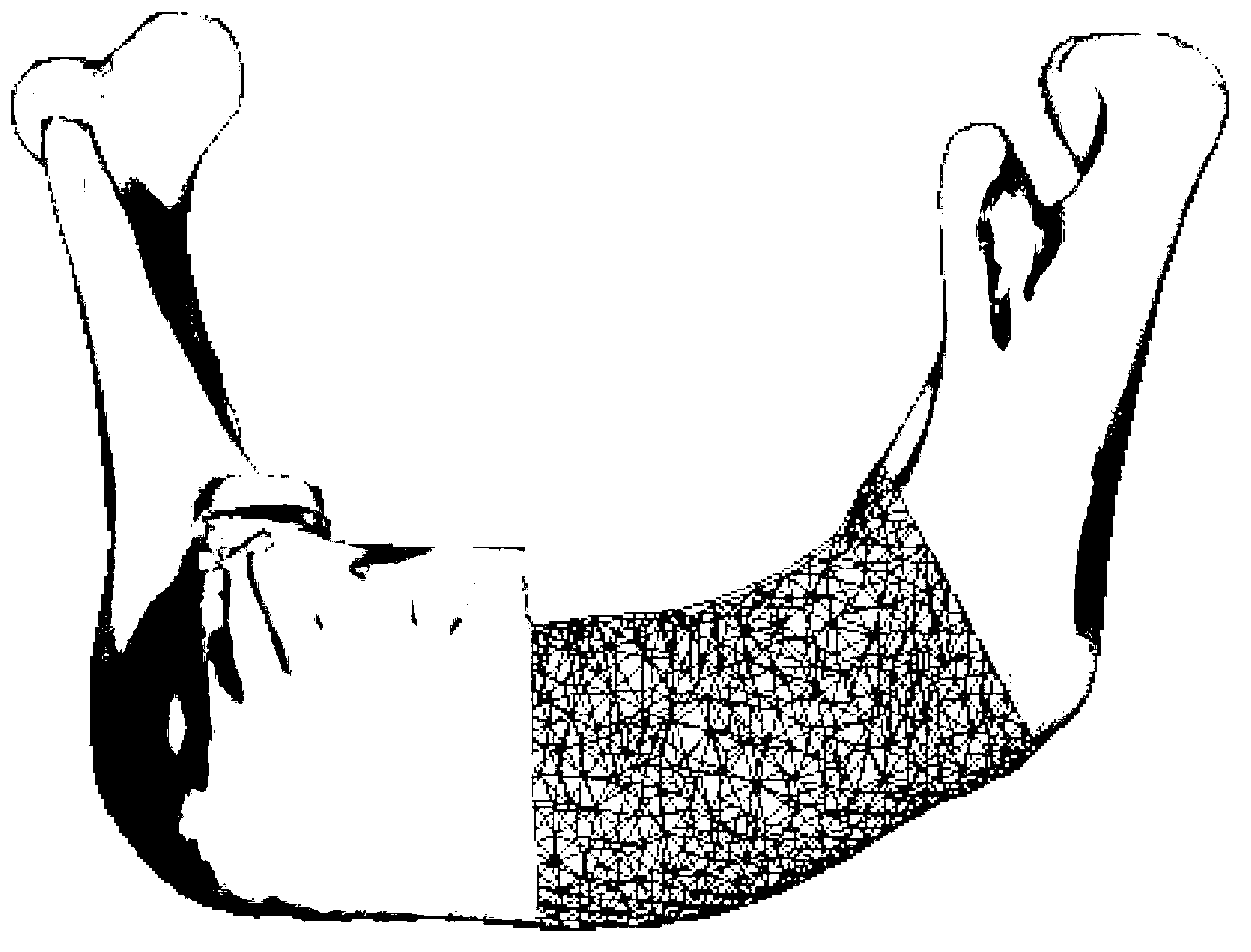

[0034] Such as figure 1 As shown, the defect is located in the distal part of the left mandibular first premolar to the distal part of the third molar, with a length of approximately 4 cm.

[0035] Firstly, perform spiral CT scanning on the mandibular defect: the MX-8000 spiral CT produced by Philips Company is used for scanning, the scanning plane is parallel to the orbito-auricular plane, and the scanning range is from the upper orbital edge to the lower edge of the mandible to obtain the patient's original cross-section image. Then use the 3D visualization technology and the 3D reconstruction software 3DMSR (3-Dimensional Medicine Surface Rendering) independently written by Jima Fei Company to carry out 3D reconstruction of these discrete data, transform it into an image with an intuitive three-dimensional effect, and obtain the mandible in STL format 3D bone model;

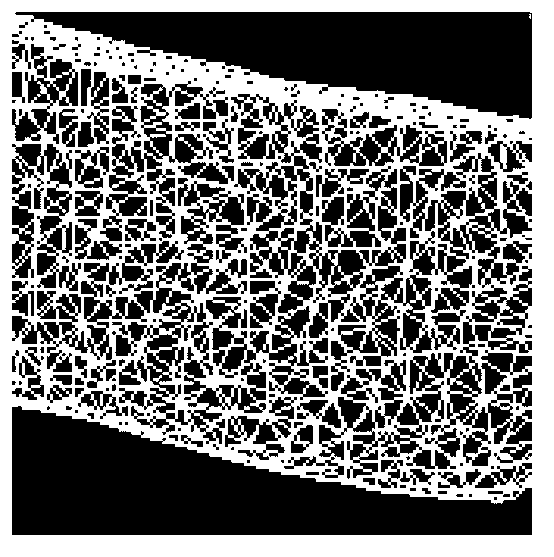

[0036] Input the image data in STL format into the software MIMICS10.1, identify and reconstruct compact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com