Ultrasonic generator based on linear frequency modulation technology and method for detecting metal welding seam defects by adopting same

A technology of linear frequency modulation and linear frequency modulation signals, which is applied in the analysis of solids by sound waves/ultrasonic waves/infrasonic waves, and fluids using vibrations, etc. It can solve the problems of poor detection ability of small defects and short propagation distance of ultrasonic signals, so as to improve identification, The effect of improved recognition accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

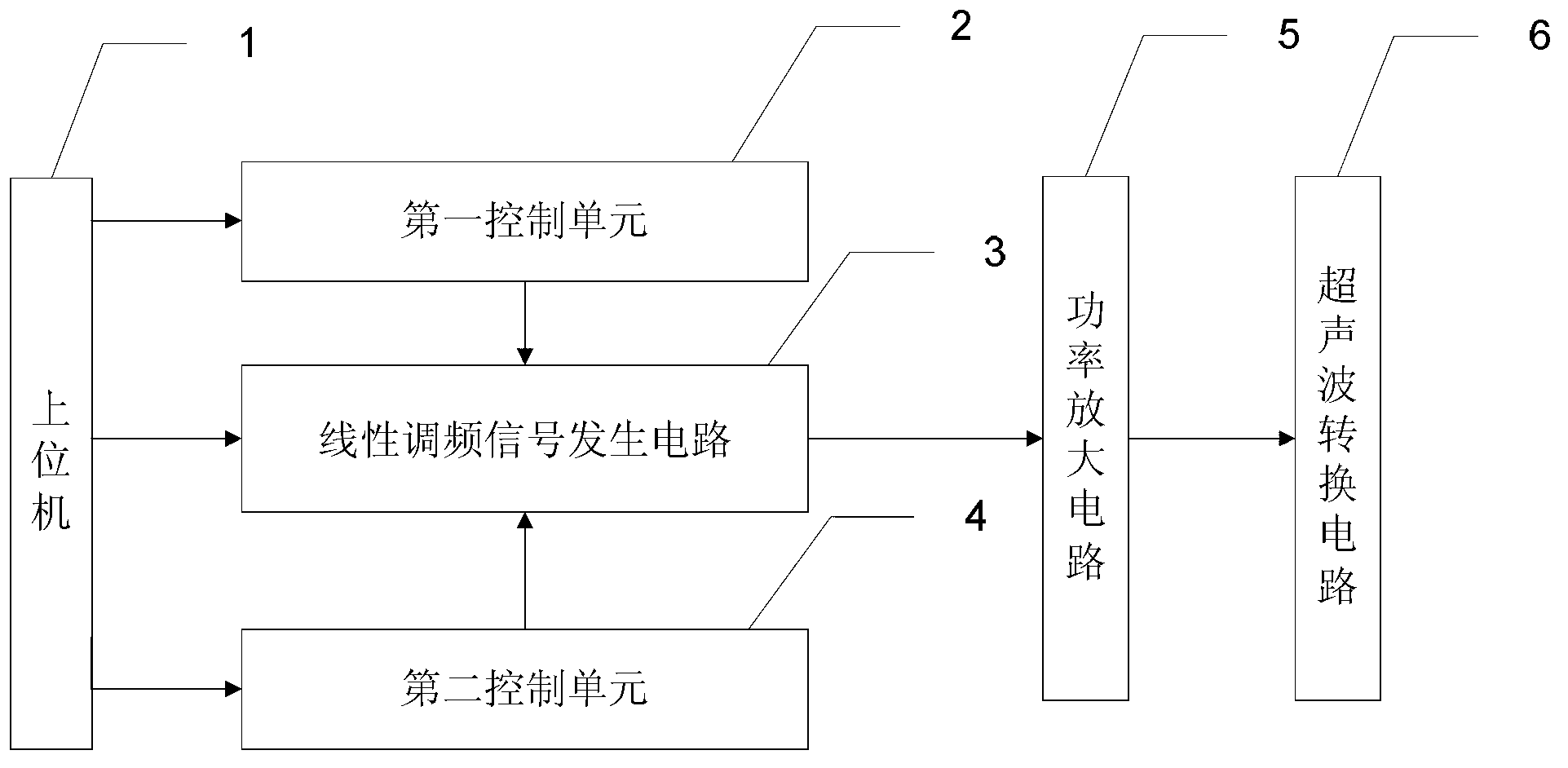

[0023] Specific implementation mode one: combine figure 1 Describe this embodiment, a kind of ultrasonic generator based on chirp technology in this embodiment, the ultrasonic generator is composed of a host computer 1, a first control unit 2, a chirp signal generating circuit 3, a second control unit 4, a power amplifier Circuit 5 and ultrasonic conversion circuit 6 are formed;

[0024] The control signal output end of the first control unit of the host computer 1 is connected to the control signal input end of the first control unit 2, and the control signal output end of the first control unit 2 is connected to the No. 1 control signal input end of the chirp signal generating circuit 3, and the upper The frequency modulation signal control signal output end of machine 1 is connected to the No. 2 control signal input end of linear frequency modulation signal generating circuit 3, the second control signal output end of host computer 1 is connected to the control signal input...

specific Embodiment approach 2

[0029] Embodiment 2: This embodiment is a further description of the ultrasonic generator based on the chirp technology described in Embodiment 1. The chirp signal generating circuit 3 is realized by a chip modeled as AD9910.

specific Embodiment approach 3

[0030] Specific embodiment three: the embodiment is a further description of the ultrasonic generator based on the chirp technology described in the specific embodiment one. The ultrasonic conversion circuit 6 adopts an ultrasonic straight probe, an ultrasonic oblique probe, an ultrasonic focusing probe, an ultrasonic band probe or SAW probe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pulse width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com