High-filling high-temperature-resistant environment-friendly paper base material and preparation method thereof

A high-temperature-resistant, environmentally-friendly paper technology, applied in the field of composite filling substrates, can solve problems such as waste of resources, insufficient high-temperature resistance, and urgency, and achieve reduced probability of failure, good stiffness and flatness, and high-value recycling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

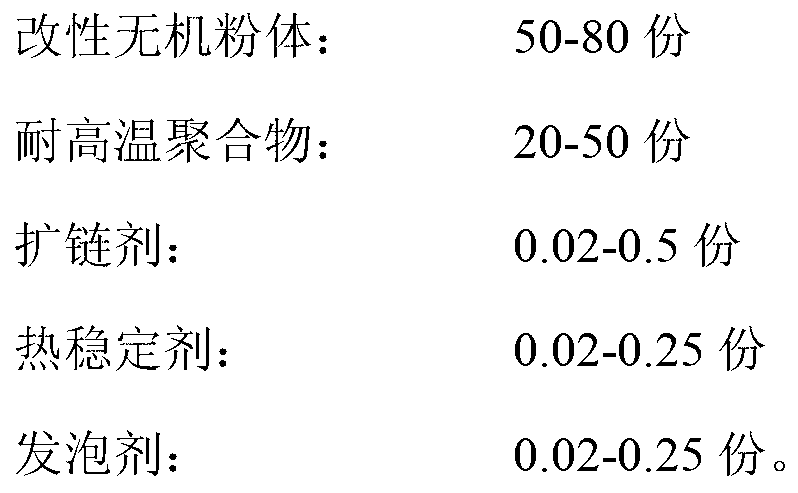

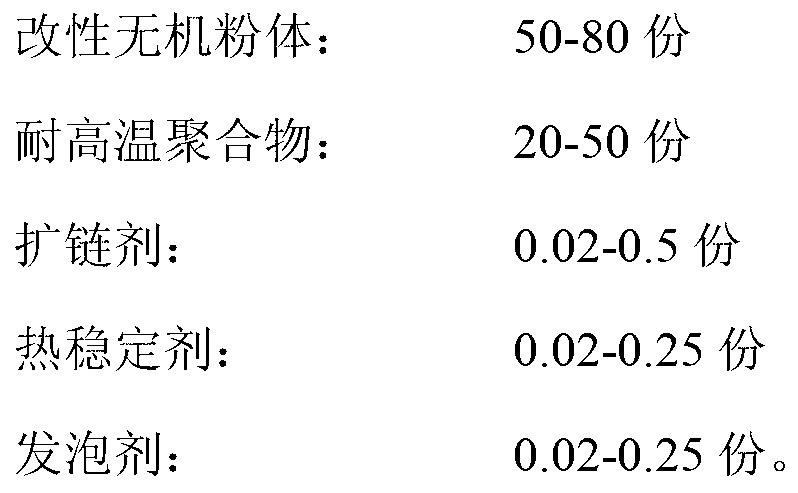

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: A kind of highly filled and high temperature resistant environmental protection paper base material and its preparation method, its preparation process is:

[0028] (1) Preparation of modified calcium carbonate powder: Add 100 parts of dry calcium carbonate powder with a particle size of 1000 mesh and 1 part of γ-methacryloxypropyl trimethoxysilane into a high-speed mixer that can be heated , heated up to 80°C and stirred at high speed for 120min, the modified calcium carbonate powder can be obtained;

[0029] (2) Preparation of mixed pellets: take 50 parts of modified calcium carbonate powder obtained in step (1), 50 parts of polyethylene terephthalate, intrinsic viscosity 0.65dL / g, and place in an oven at 120°C before use Dry for 4 hours, add them together into the internal mixer, melt and blend at 265°C for 30 minutes, and then extrude and granulate through single-screw to obtain the mixed pellets;

[0030] (3) Preparation of environmentally friendly p...

Embodiment 2

[0032] Embodiment 2: A kind of high-filling high-temperature-resistant environmentally-friendly paper base material and its preparation method, its preparation process is:

[0033] (1) Preparation of modified calcium carbonate powder: Add 100 parts of dry calcium carbonate powder with a particle size of 2000 mesh and 0.7 part of γ-chloropropyltriethoxysilane into a high-speed mixer that can be heated, and heat up to 100 ℃ and high-speed stirring for 60 minutes, the modified calcium carbonate powder can be obtained;

[0034] (2) Preparation of mixed pellets: take 65 parts of modified calcium carbonate powder obtained in step (1), 35 parts of polyethylene terephthalate, intrinsic viscosity 0.60dL / g, and place in an oven at 120°C before use Dry for 4 hours, add them together into the internal mixer, melt and blend at 265°C for 30 minutes, and then extrude and granulate through single-screw to obtain the mixed pellets;

[0035] (3) Preparation of environmentally friendly paper su...

Embodiment 3

[0037] Embodiment 3: A kind of highly filled and high temperature resistant environmental protection paper substrate and its preparation method, its preparation process is:

[0038] (1) Preparation of modified calcium carbonate powder: 100 parts of dry calcium carbonate powder with a particle size of 4000 mesh and 0.5 part of isopropyl dioleate (dioctyl phosphate acyloxy) titanate Add it into a high-speed mixer that can heat up, heat up to 120°C and stir at a high speed for 30 minutes to obtain modified calcium carbonate powder;

[0039] (2) Preparation of mixed pellets: take 80 parts of modified calcium carbonate powder obtained in step (1), 20 parts of recycled polyethylene terephthalate, intrinsic viscosity 0.75dL / g, and dry in an oven at 120°C before use Dry in medium for 4 hours, put them into the internal mixer together, melt and blend at 265°C for 30 minutes, and then extrude and granulate through single screw to get the mixed pellets;

[0040](3) Preparation of enviro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com