Alternative high-throughput electroporation device

An electroporation, high-throughput technology, applied in the field of electroporation, can solve the problem of high processing cost, and achieve the effect of low cost, good heat dissipation, and automatic gene function screening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

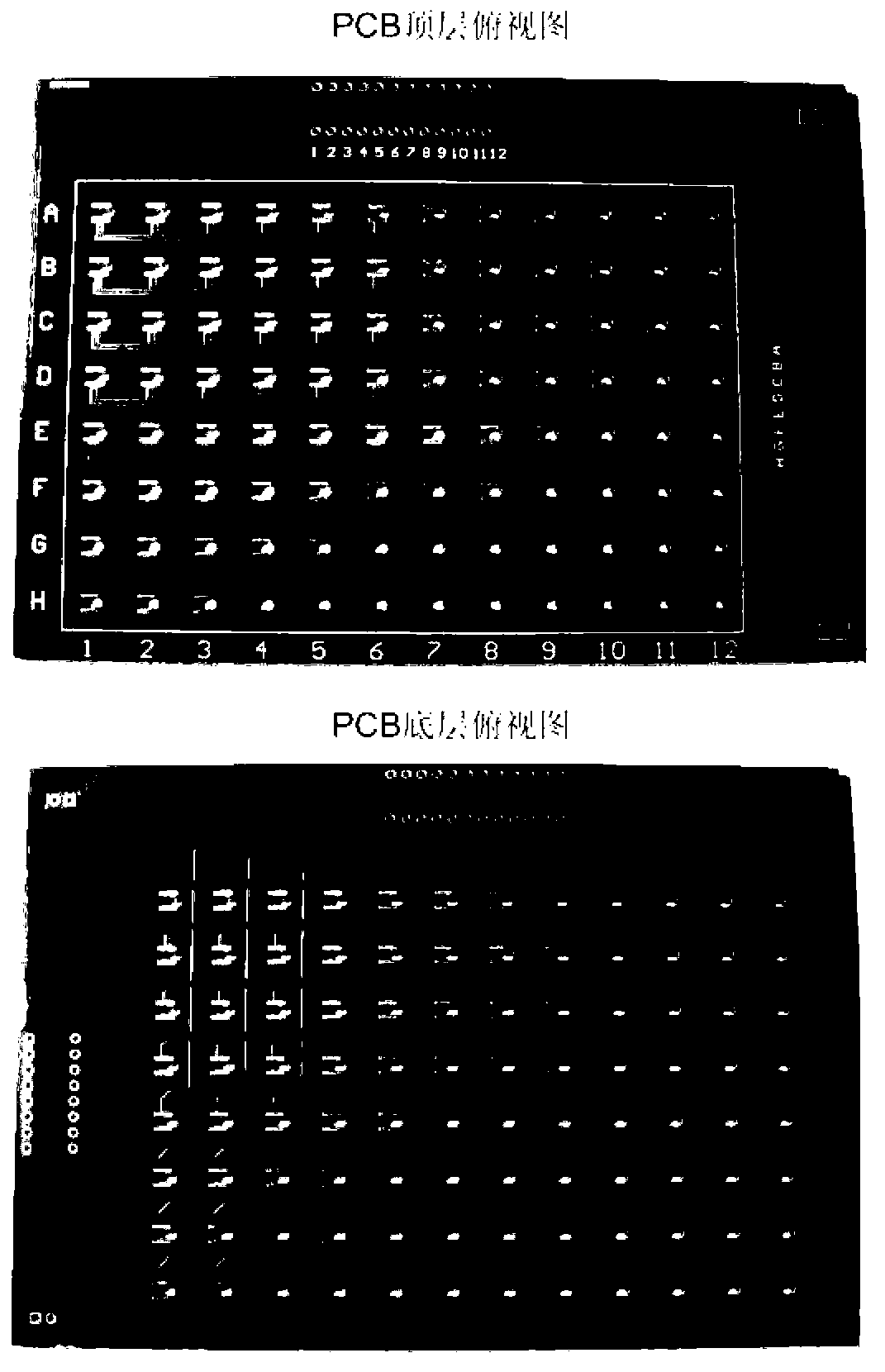

[0034] Embodiment 1. A high-throughput electroporation device based on a printed circuit board. The electroporation electrodes are metal parallel plates perpendicular to the substrate.

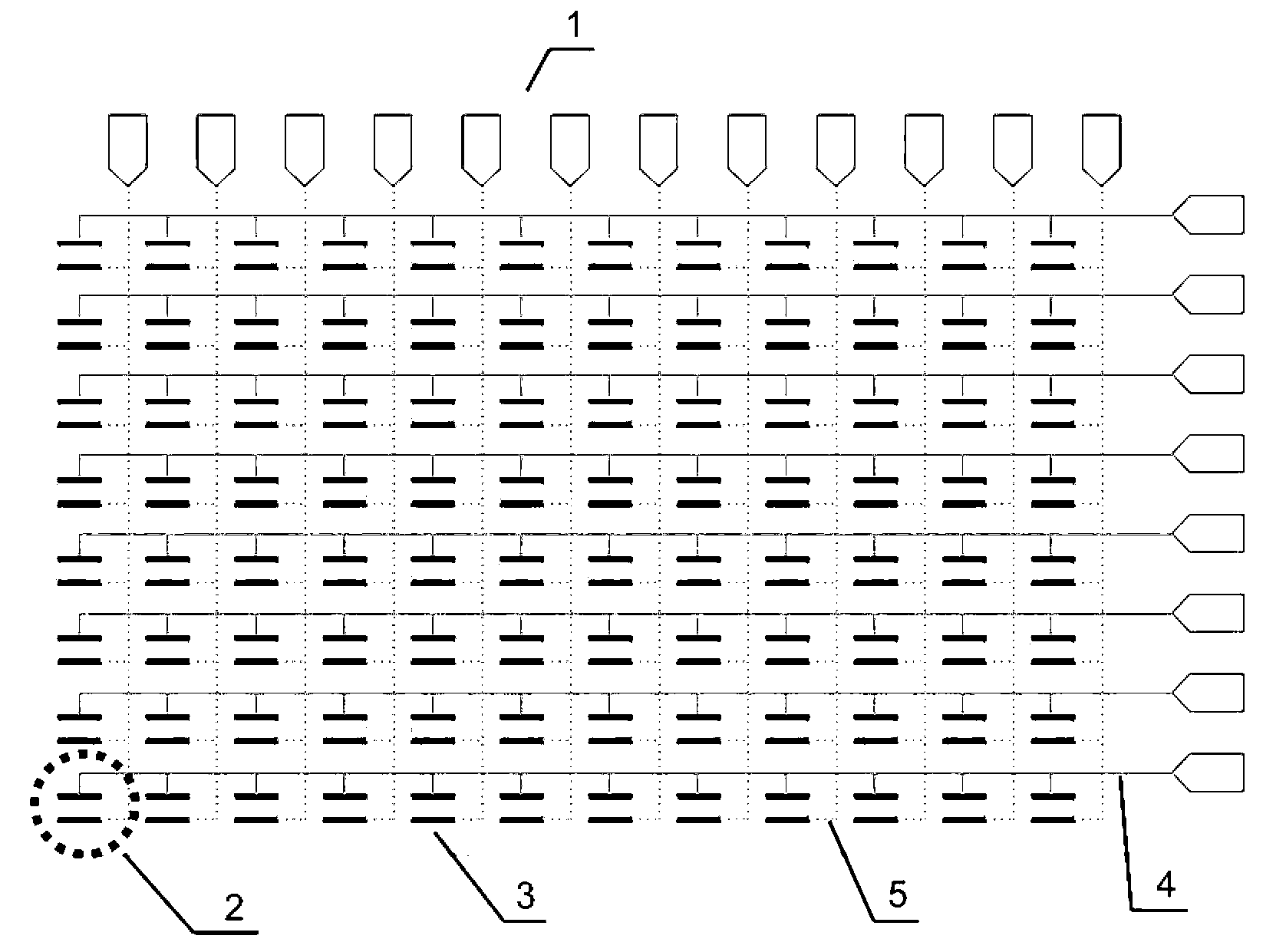

[0035] figure 1 A top view of the electroporation device provided in this example, which can be matched with a 96-well plate.

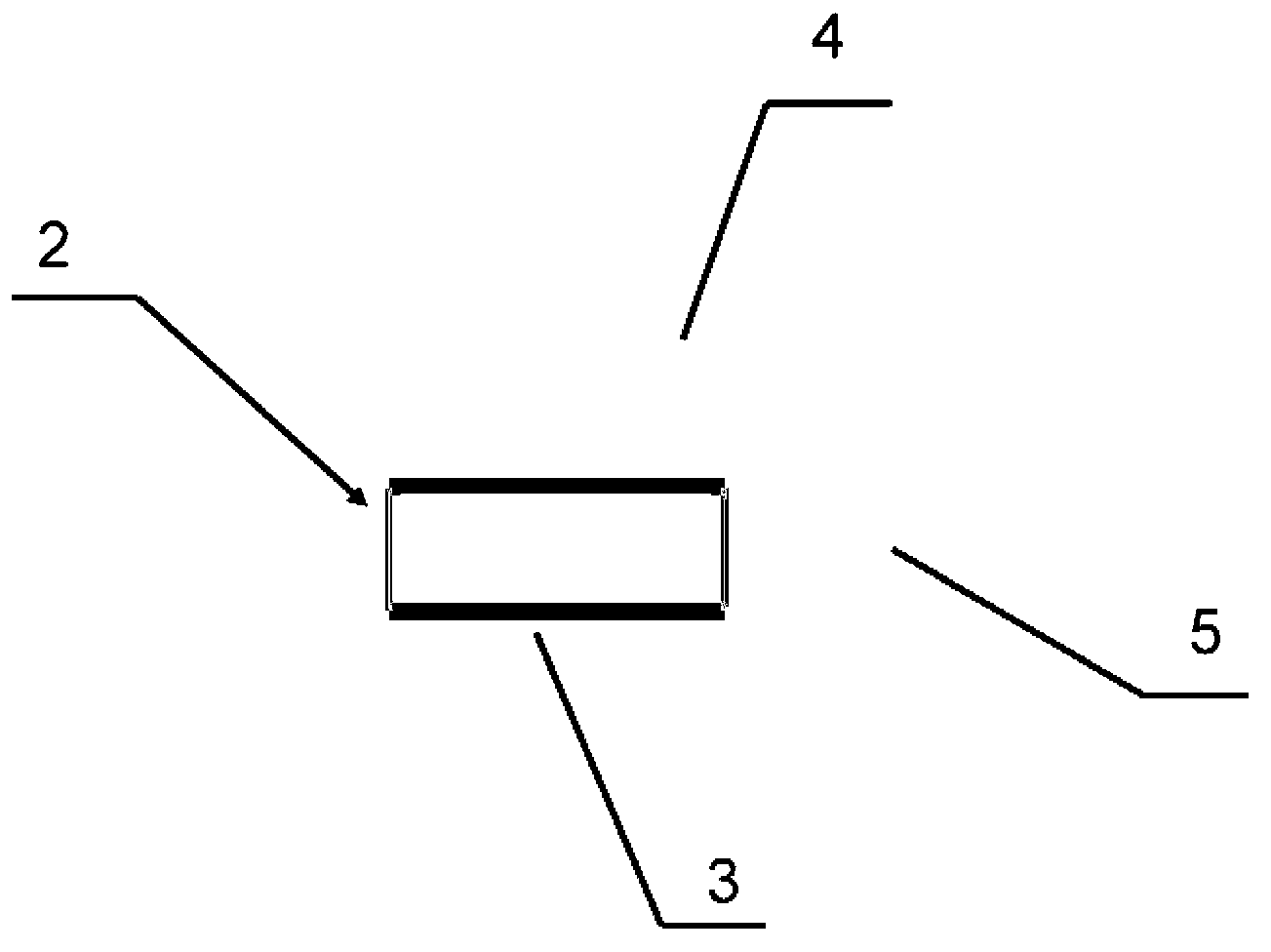

[0036] Such as figure 1 As shown, the electroporation device in this embodiment includes a substrate 1 on which 96 through holes 2 are arranged, and are matched with a 96-well plate. One electrode 3 is provided on the side wall of each through hole 2, that is, one pair of electrodes. The distance between the two electrode plates is 2mm.

[0037] In order to achieve selective control of each through hole with as few pads as possible, all electrodes on the upper side of a row of 12 holes are commonly connected to the top layer wires 4 distributed along each row on the top of the substrate 1, while all electrodes on the lower side of a row of 8 holes are connected to ...

Embodiment 2

[0044] Embodiment 2, a high-throughput electroporation device based on a printed circuit board, the electroporation electrodes are parallel to the substrate

[0045] This embodiment is similar to Embodiment 1 in that the electroporation device is made of a PCB, and the difference is that this embodiment uses a circular PCB through hole to carry the electroporation system. Similar to Embodiment 1, the inside of the PCB through hole is covered with a metal layer. In order to generate the electrode pairs required for electroporation, the metal of the PCB passing through the inner wall can be milled off with a drill (such as Figure 7 shown), so that the metal layers on the top and bottom of the PCB can become electroporation electrodes. An alternative processing method is: use a drill to drill directly at the intersection of the upper and lower metal traces. As long as the diameter of the drill is smaller than the width of the metal traces, similar Figure 7 The structure shown ...

Embodiment 3

[0048] Embodiment 3. A high-throughput electroporation device based on a printed circuit board. The electroporation electrodes are metal parallel plates perpendicular to the substrate. The distance between the two electrode plates is 1mm. Its concrete experimental process is similar to embodiment 1. Compared with Example 1, the distance between electrodes is smaller, so the voltage required for electroporation is smaller.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com