CO2 corrosion resistant pipeline steel used for surface gathering and preparation method of same

A pipeline steel, gathering and transportation technology, applied in the field of CO2 corrosion-resistant pipeline steel for ground gathering and transportation and its preparation, can solve the problems of tensile strength, yield strength, lack of elongation, increased cost, limited application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

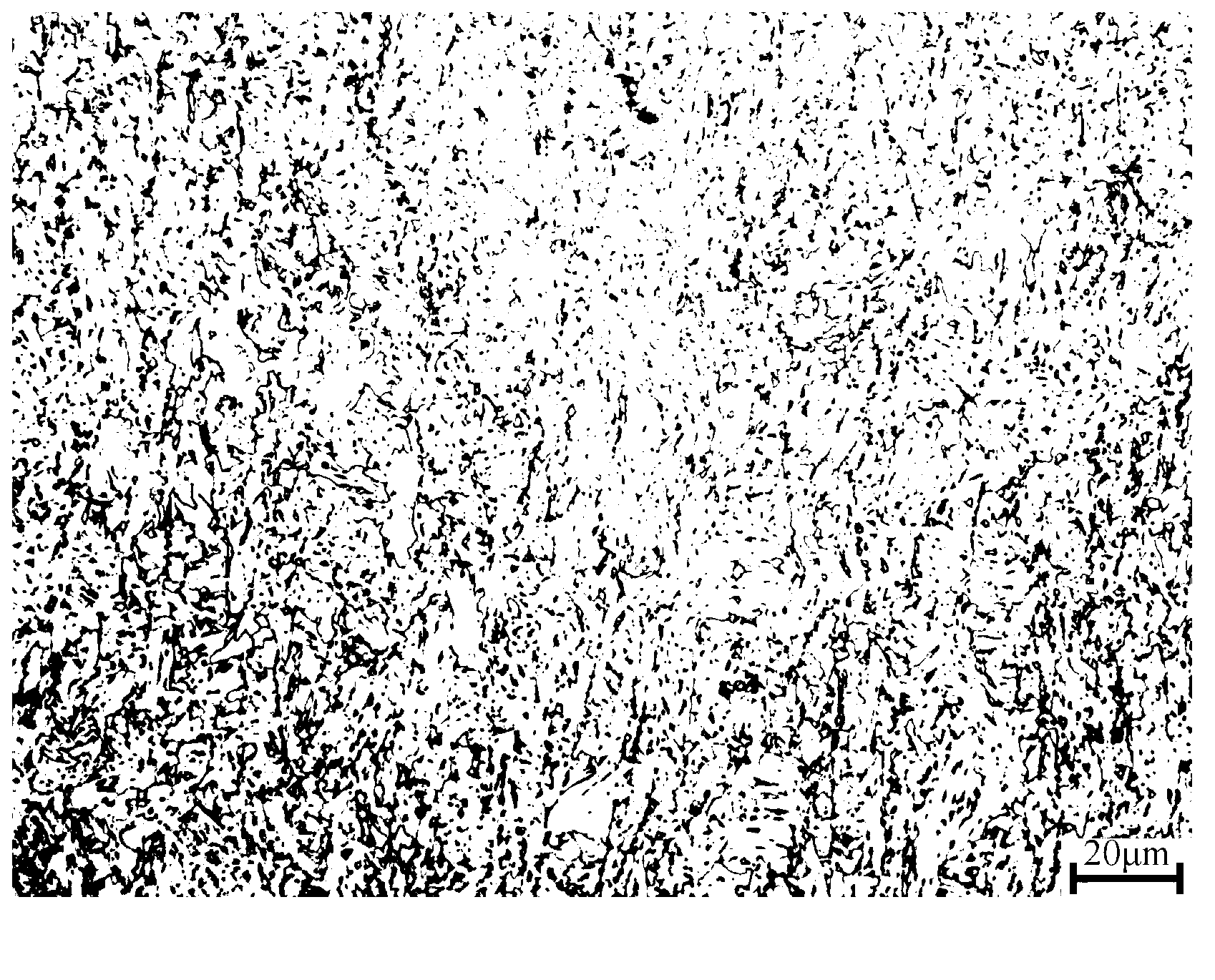

Image

Examples

Embodiment 1

[0068] The thickness of the corrosion-resistant steel plate in this example is 8 mm.

[0069] The pipeline steel of the present embodiment is composed of the following components by weight percentage:

[0070] C0.03%, Si0.18%, Mn1.35%, P0.006%, S0.003%, Nb0.025%, V0.05%, Ti0.006%, Cr1.1%, Mo0.25%, Cu0.25%, Ni0.24%, the balance is Fe and inevitable impurities;

[0071] The preparation method includes the following steps:

[0072] The first step is to smelt, cast and forge steel billets according to the above-mentioned components; use electromagnetic induction furnace vacuum smelting during smelting, and fill with argon gas for protection;

[0073] The second step, heating: the billet is heated at 1200 ° C, and then enters the third step after being kept for 2 hours and soaked;

[0074] The third step, rough rolling: the starting rolling temperature is 1170 °C, the final rolling temperature is 1070 °C, the rolling passes are 4 times, and the cumulative reduction rate is 65%; ...

Embodiment 2

[0079] The thickness of the corrosion-resistant steel plate in this example is 12 mm.

[0080] The pipeline steel of the present embodiment is composed of the following components by weight percentage:

[0081] C0.04%, Si0.15%, Mn1.01%, P0.006%, S0.004%, Nb0.03%, V0.03%, Ti0.01%, Cr1.65%, Mo0.26%, Cu0.25%, Ni0.26%, the balance is Fe and inevitable impurities;

[0082] The preparation method includes the following steps:

[0083] The first step is to smelt, cast and forge steel billets according to the above-mentioned components; use electromagnetic induction furnace vacuum smelting during smelting, and fill with argon gas for protection;

[0084] The second step, heating: the billet is heated at 1200 ° C, and then enters the third step after being kept for 2 hours and soaked;

[0085] The third step, rough rolling: the starting rolling temperature is 1150 °C, the final rolling temperature is 1050 °C, the rolling passes are 4 times, and the cumulative reduction rate is 60%; ...

Embodiment 3

[0090] The thickness of the corrosion-resistant steel plate in this example is 12 mm.

[0091] The pipeline steel of the present embodiment is composed of the following components by weight percentage:

[0092] C0.06%, Si0.24%, Mn0.85%, P0.006%, S0.003%, Nb0.05%, V0.02%, Ti0.01%, Cr2.3%, Mo0.18%, Cu0.16%, Ni0.12%, the balance is Fe and inevitable impurities;

[0093] The preparation method includes the following steps:

[0094] The first step is to smelt, cast and forge steel billets according to the above-mentioned components; use electromagnetic induction furnace vacuum smelting during smelting, and fill with argon gas for protection;

[0095] The second step, heating: the billet is heated at 1200 ° C, and then enters the third step after being kept for 2 hours and soaked;

[0096] The third step, rough rolling: the starting rolling temperature is 1170 °C, the final rolling temperature is 1070 °C, the rolling passes are 4 times, and the cumulative reduction rate is 60%;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com