Preparation method for oil-free polypropylene staple fibers with static electricity

A technology of polypropylene staple fiber and static electricity, which is applied in the field of polypropylene staple fiber preparation and can solve problems such as harmfulness to human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

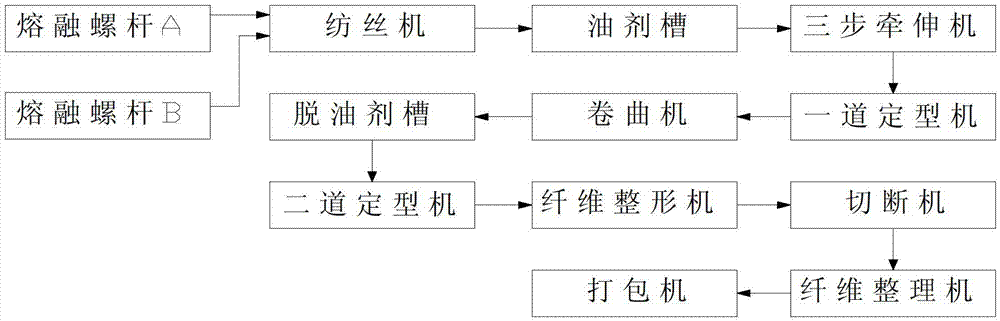

[0016] The present invention provides a kind of preparation method of polypropylene staple fiber without oil agent and with electrostatic function, the flow process is as follows figure 1 shown, including the following:

[0017] Add polypropylene chips with a polymelt index of 64g / 10min into the melting screw A as the skin layer. The temperature of each zone of the screw A is 160-170°C in zone 1, preferably 165°C, 170-180°C in zone 2, preferably 175°C, and 180°C in zone 3. ~190°C, preferably 183°C, zone 4 182-200°C, preferably 185°C, zone 5 185-230°C, preferably 188°C, zone 6 185-230°C, preferably 188°C, zone 7 185-230°C, preferably 188°C °C, the melt temperature of the melting screw A is preferably 160 °C to 230 °C, more preferably 188 °C, the number of revolutions is preferably 38 to 52 revolutions, more preferably 44 revolutions, and the current is preferably 66 to 120 amps, more preferably 97 amps;

[0018] Add polypropylene chips with a melt index of 32g / 10min into the ...

Embodiment 1

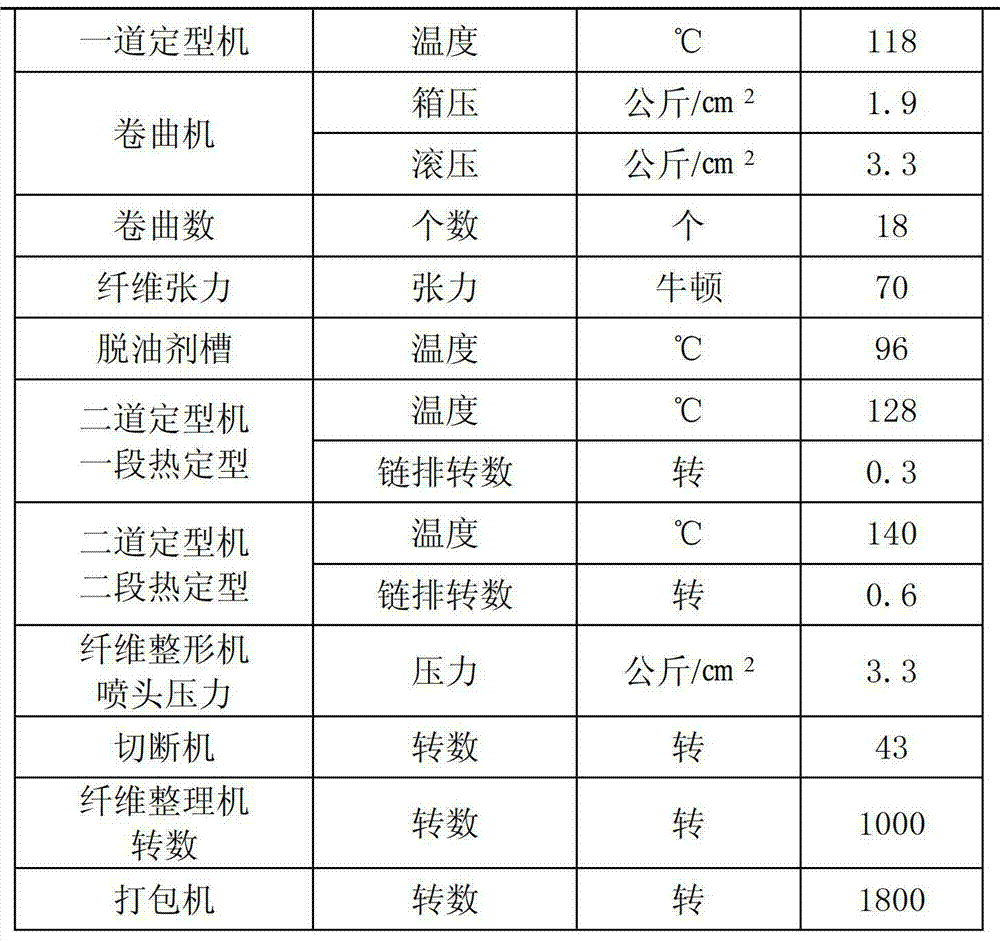

[0028] Add polypropylene slices with a melt index of 64g / 10min to melting screw A as the skin layer, and add polypropylene slices with a melt index of 32g / 10min to melt screw B as the core layer, and the skin layer and core layer are 40:60 by mass Add it to the metering pump of the spinning machine. After the fiber is formed, it passes through the oiling roller in the oil tank, the three-step drafting machine, the first setting machine, the crimping machine, the deoiling agent tank, and the second setting machine to obtain fiber bundles. The bundles pass through the fiber shaping machine, cutting machine, fiber finishing machine and baler to obtain oil-free polypropylene staple fibers with electrostatic function. The temperature in each zone of screw A is 160°C in zone 1, 170°C in zone 2, and 180°C in zone 3. Zone 4 is 182°C, Zone 5 is 185°C, Zone 6 is 185°C, Zone 7 is 185°C, the temperature of each zone of screw B is 230°C in Zone 1, Zone 2 is 240°C, Zone 3 is 250°C, Zone 4 is...

Embodiment 2

[0035] Add polypropylene slices with a melt index of 64g / 10min to melting screw A as the skin layer, and add polypropylene slices with a melt index of 32g / 10min to melt screw B as the core layer, and the skin layer and core layer are 50:50 by mass Add it to the metering pump of the spinning machine. After the fiber is formed, it passes through the oiling roller in the oil tank, the three-step drafting machine, the first setting machine, the crimping machine, the deoiling agent tank, and the second setting machine to obtain fiber bundles. The bundles pass through the fiber shaping machine, cutting machine, fiber finishing machine and baler to obtain oil-free polypropylene staple fibers with electrostatic function. The temperature in each zone of screw A is 165°C in zone 1, 175°C in zone 2, and 183°C in zone 3. Zone 4 is 185°C, Zone 5 is 188°C, Zone 6 is 188°C, Zone 7 is 188°C, the temperature of each zone of screw B is 238°C in Zone 1, Zone 2 is 245°C, Zone 3 is 253°C, Zone 4 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com