Method and device for testing gas combustion nozzle

A technology of combustion nozzles and test devices, which is applied in the direction of measuring devices, testing of mechanical parts, testing of machine/structural parts, etc., to prevent flame melting, complete and reliable data recording, and reduce temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is a method for testing a gas combustion nozzle. It connects combustible gas and high-pressure air to the nozzle to be tested and generates a swirling saturated mixed gas in the nozzle. When encountering an electric spark from a pulse igniter , That is, produce a torch by burning, observe the color, length and shape of the flame, and use sensors to detect the maximum temperature of the flame and the content of harmful gases discharged into the air, providing a design basis for the application of this type of combustion nozzle.

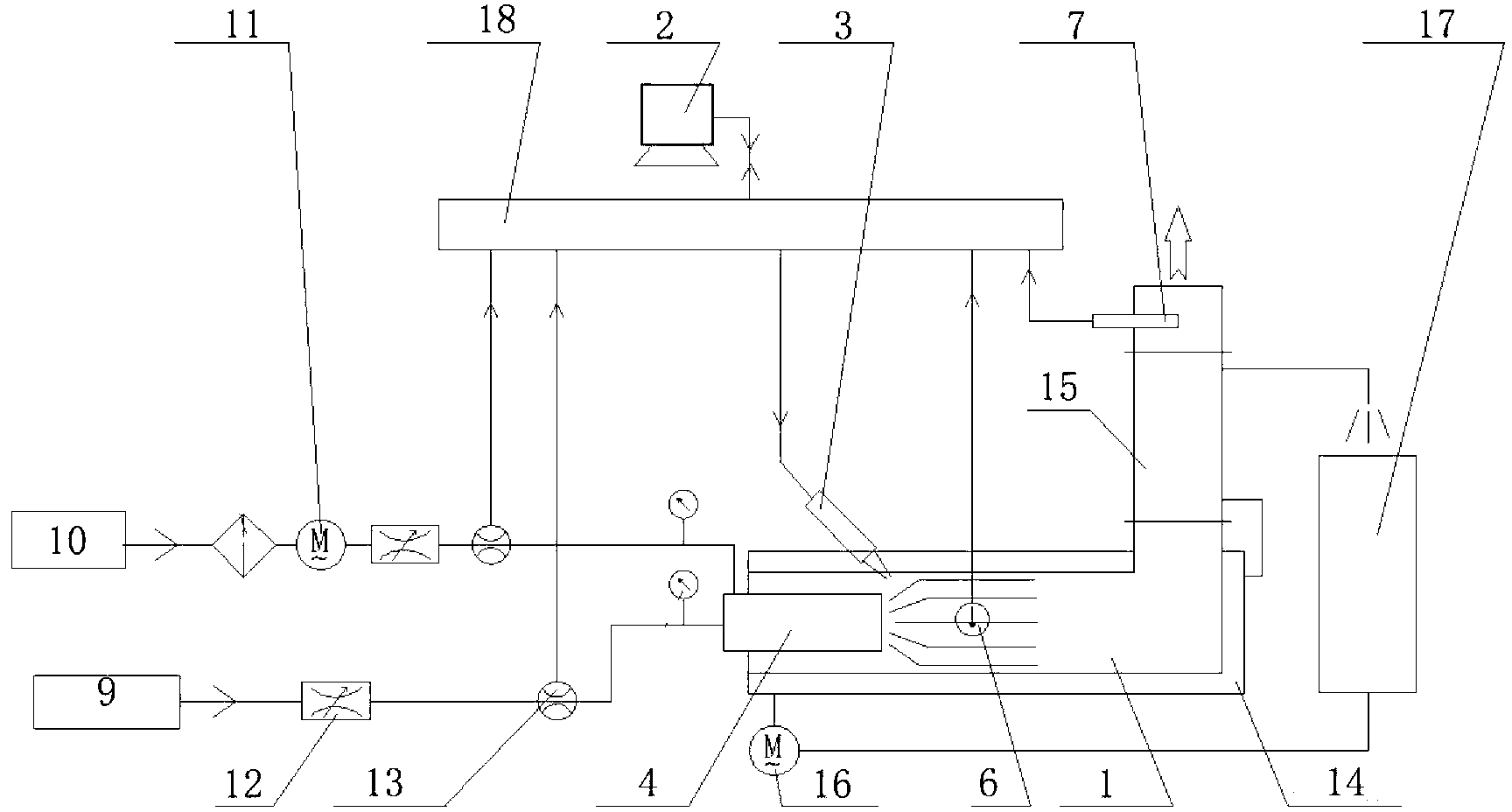

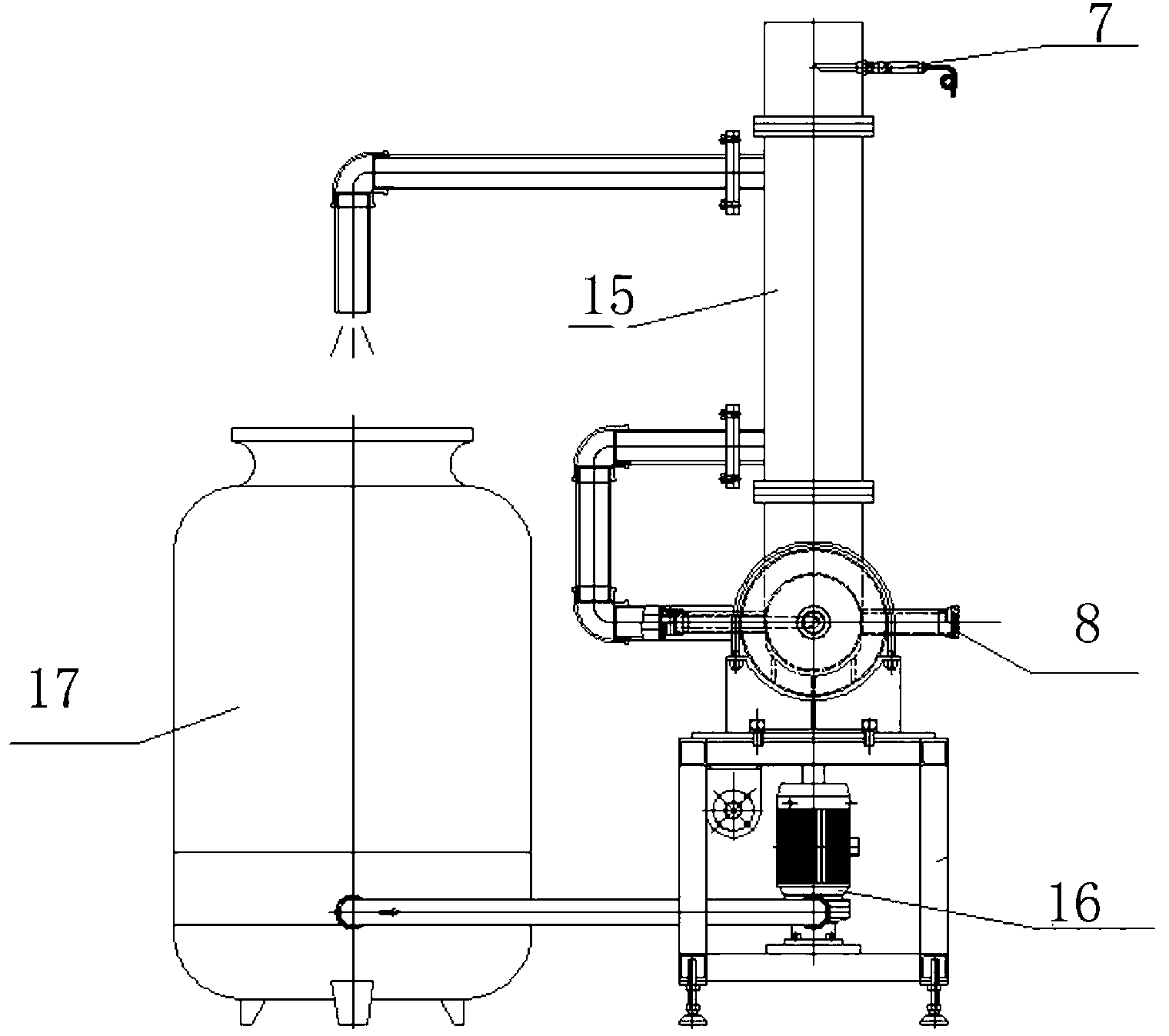

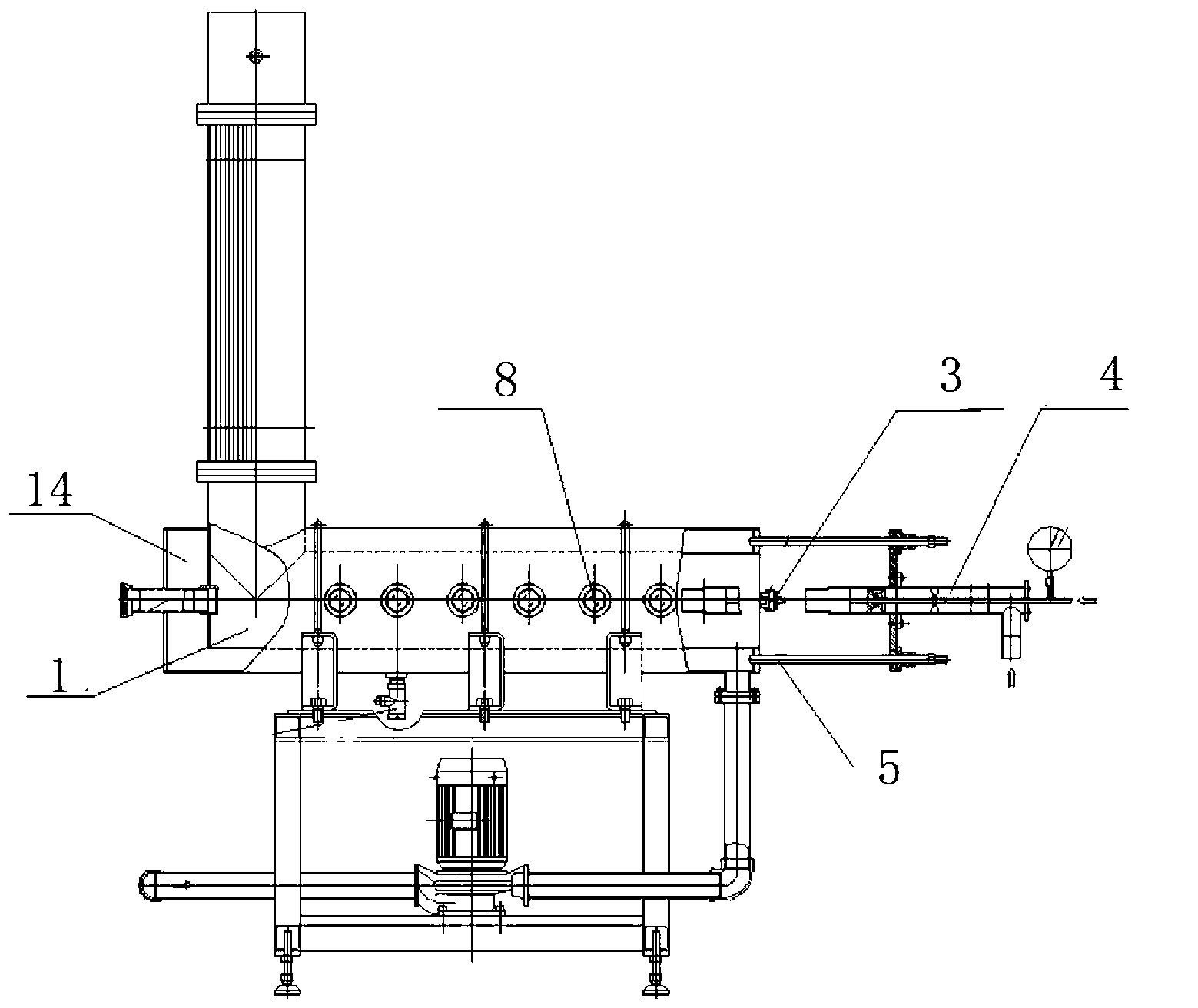

[0019] Such as Figure 1-Figure 3 As shown, the following is the equipment compatible with the gas combustion nozzle test method, which includes the combustion chamber 1, the control system 2, the pulse igniter 3, and the travel mechanism 5 for installing the nozzle 4 to be tested. The combustion chamber 1 is equipped with a temperature The sensor 6, the carbon monoxide tester 7 and the flame observation window 8, the nozzle 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com