Method for predicting crystallization state of sugarcane sugar boiling process

A technology of crystallization state and prediction method, which is applied in the field of sugarcane sugar production, to achieve the effect of facilitating timely response, improving accuracy, and strong real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

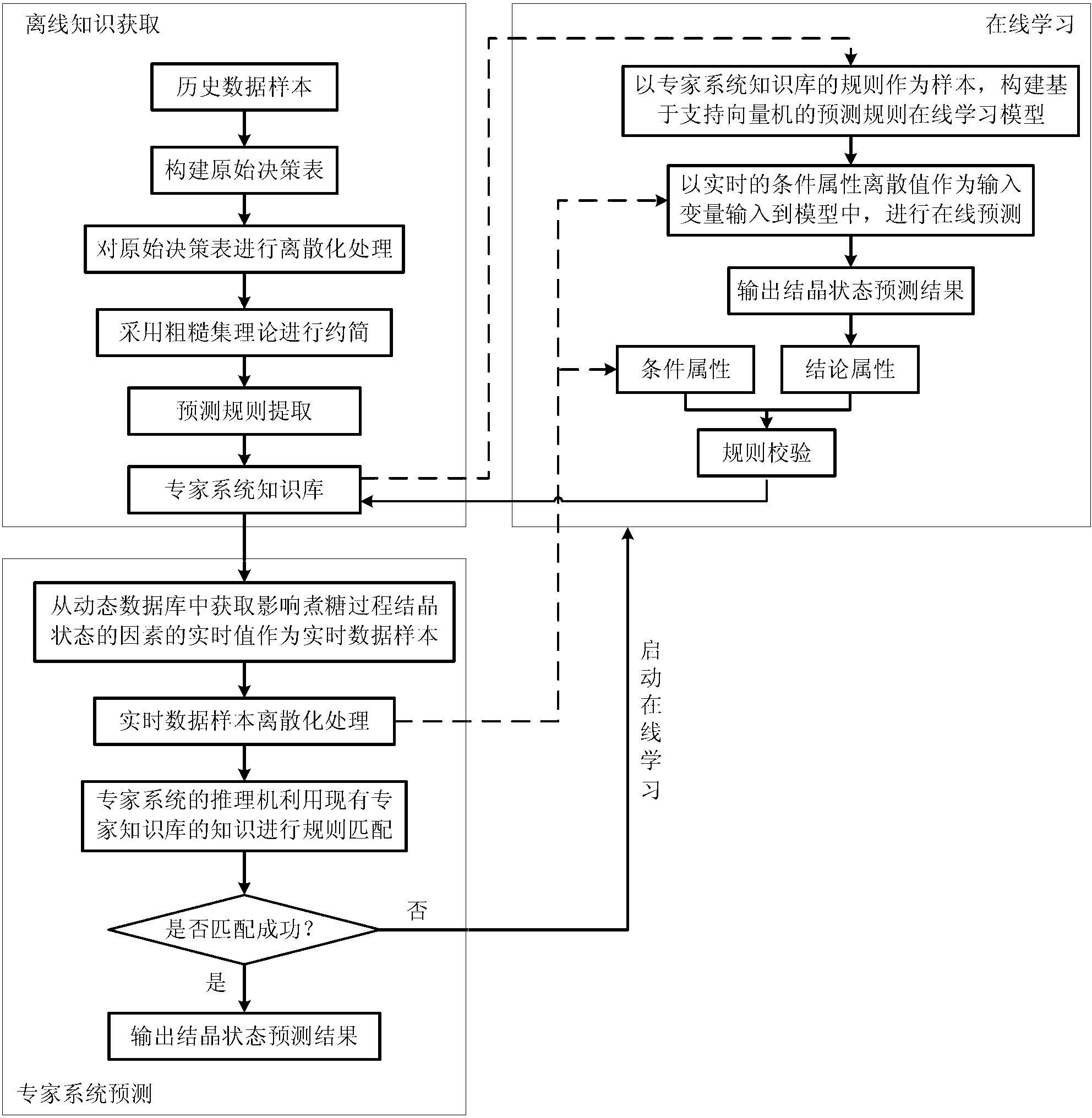

[0049] The technical solution of the present invention will be further described and illustrated with the accompanying drawings and embodiments below.

[0050] figure 1 It is a flow chart of specific steps of the method for predicting the crystallization state of the sugarcane boiling process described in the present invention. Take the implementation process of a certain sugar factory as an example to explain in further detail. Take the boiled massecuite as an example: the number of cooking cubes is 55m3; the syrup brix is 62Bx, the purity is: 85AP, the temperature is 65°C; the temperature of hot water is 68°C; the cooking stage is divided into: the initial stage, the bottom material stage, sorting stage, feeding stage, concentration stage, sugar release stage. The crystallization state prediction process of sugarcane sugar boiling process is as follows:

[0051] (1) Install an automatic monitoring platform for the crystallization process of sugar cane boiling in the sug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com