Antenna plane near-field test scanner

A scanner and plane technology, which is applied to the field of near-field test scanning devices for antenna planes, can solve the problems of improving positioning accuracy, increasing accuracy and speed, and failing to realize closed-loop control, and achieves the effects of convenient installation and debugging and simple mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

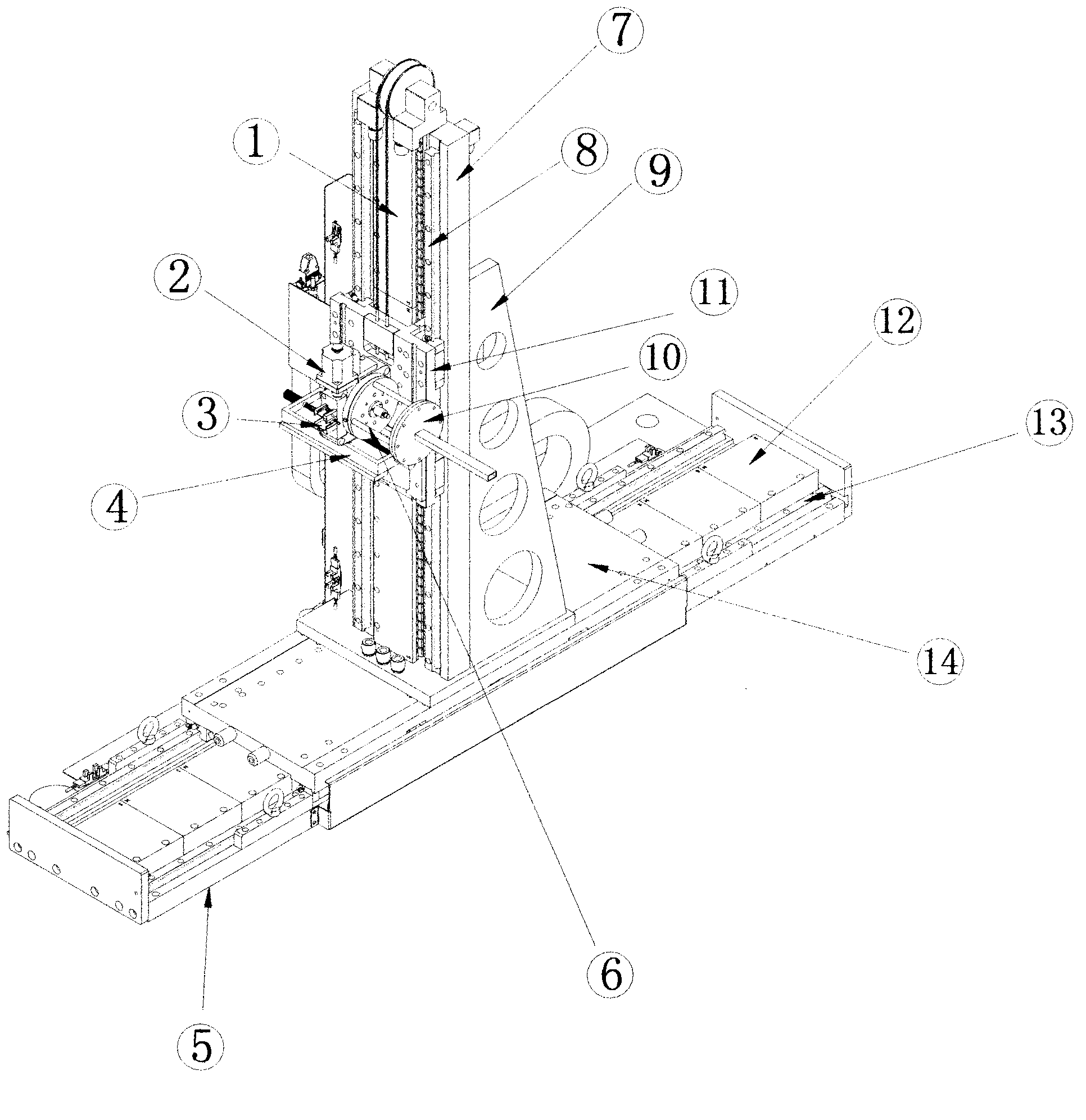

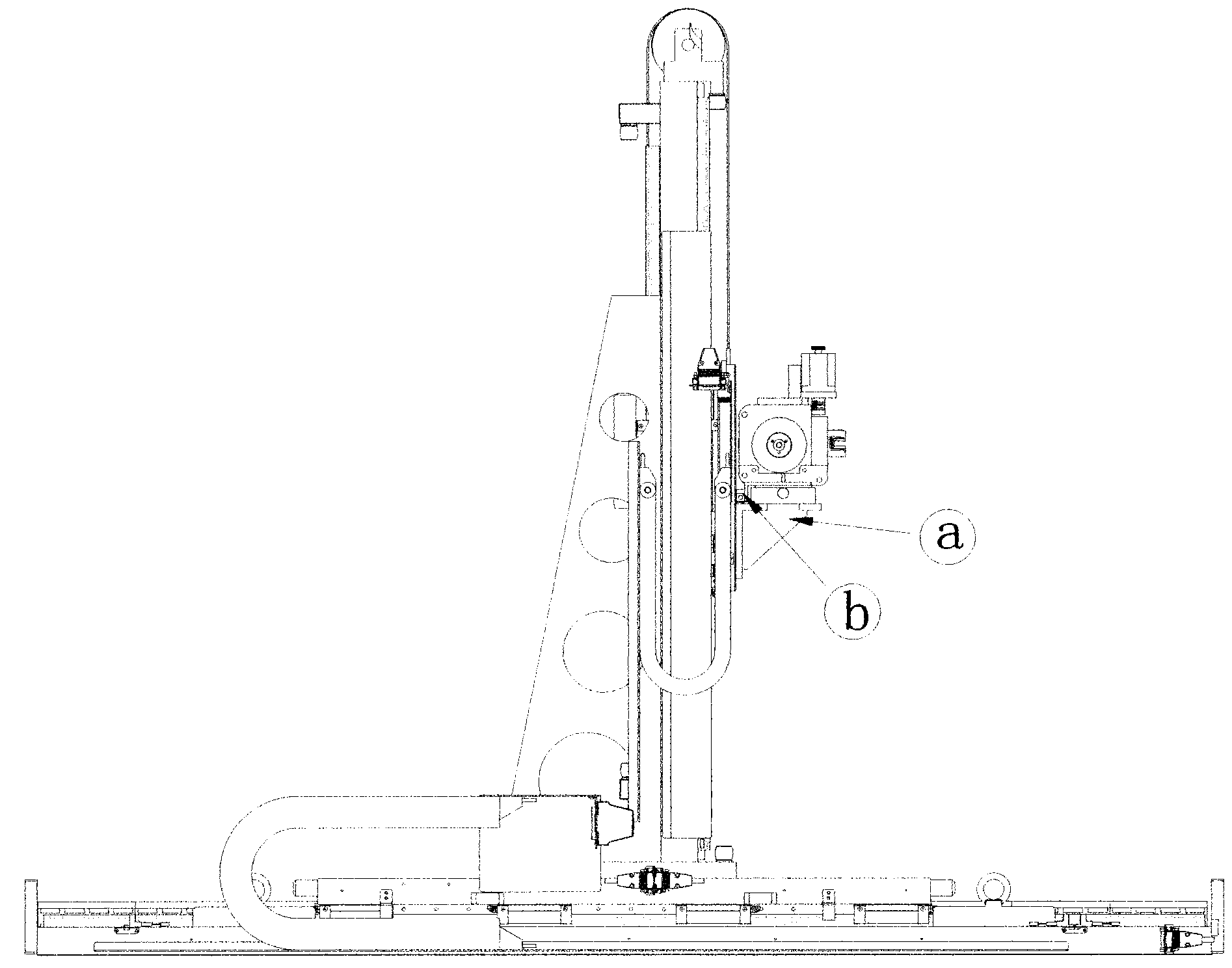

[0014] exist figure 1 Among them, the X-axis guide rail (13), the X-axis linear motor stator (12) are installed on the X-axis base (5), the Y-axis tower (7), and the Y-axis support plate (9) are installed on the X-axis linear motor mover (14). ), the Y-axis guide rail (8) Y-axis linear motor stator (1) is mounted on the Y-axis tower, the Z-axis linear platform (4) is mounted on the Y-axis linear motor mover, the P-axis one-dimensional turntable (2), and the P-axis is mounted on the turntable Squirrel cage (6) (squirrel cage-shaped support), probe (10) is installed on the squirrel cage.

[0015] Working process: Under the control of the driver, the X and Y linear motors can drive the probe to do two-dimensional movement, and the P-axis one-dimensional turntable can also rotate. The data measured by the probe can be transmitted to the PC in real time through the cable and position signal.

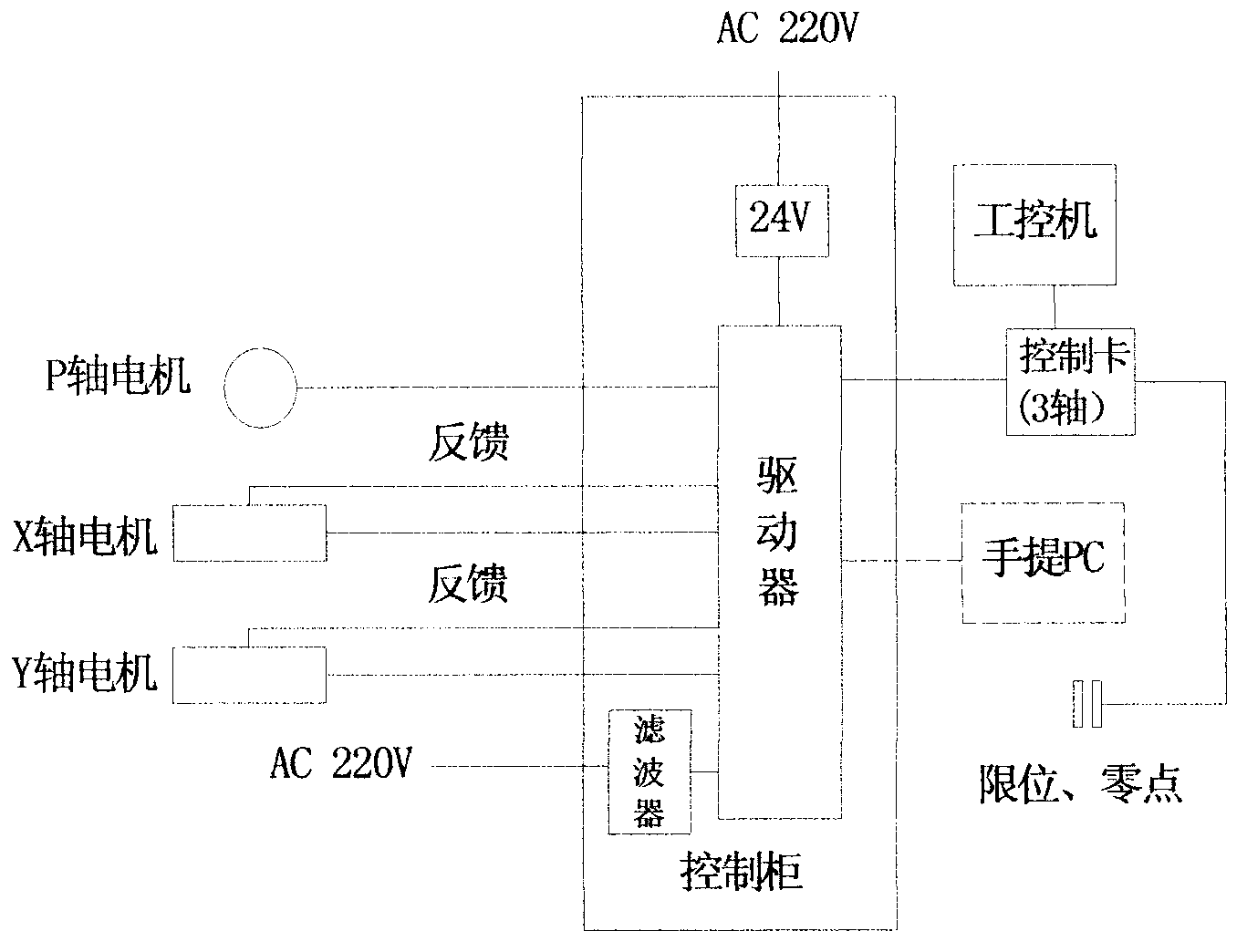

[0016] exist image 3 , shows the system control block diagram, the control system is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com