Polyhedron main substrate, manufacturing method and processing method thereof

A manufacturing method and technology of the main substrate, which are applied to the exposure device, installation, optics, etc. of the photoengraving process, can solve the problems of excessive quality, difficult workability, long delivery time, etc., and achieve good dynamic performance and stability. The overall structure is compact and efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

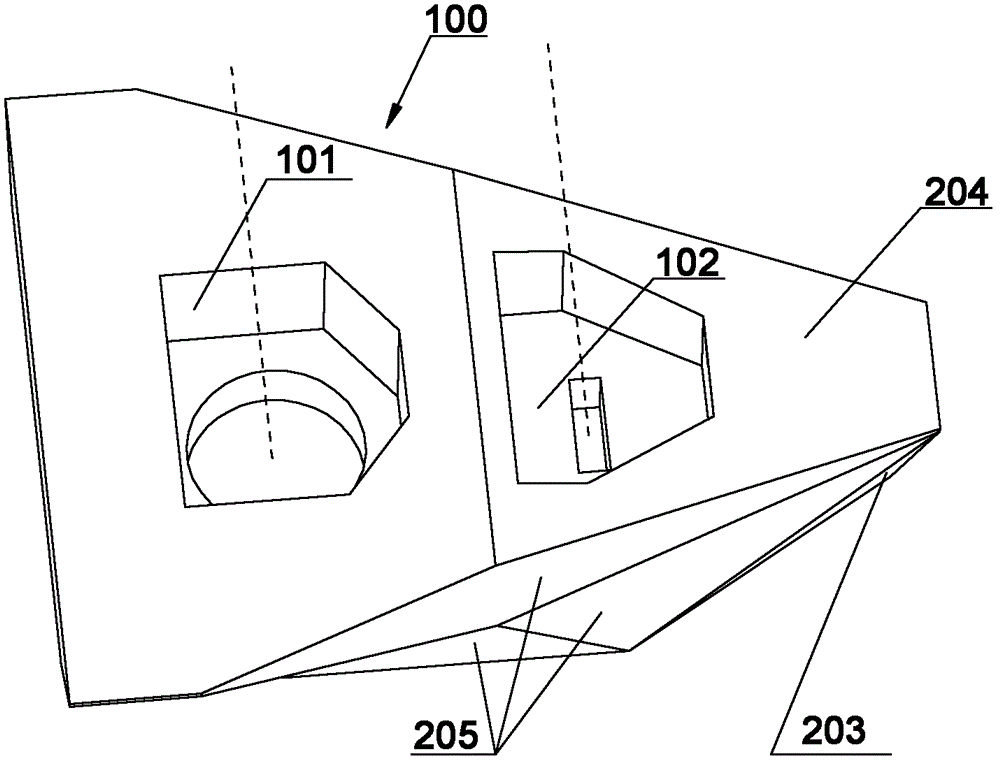

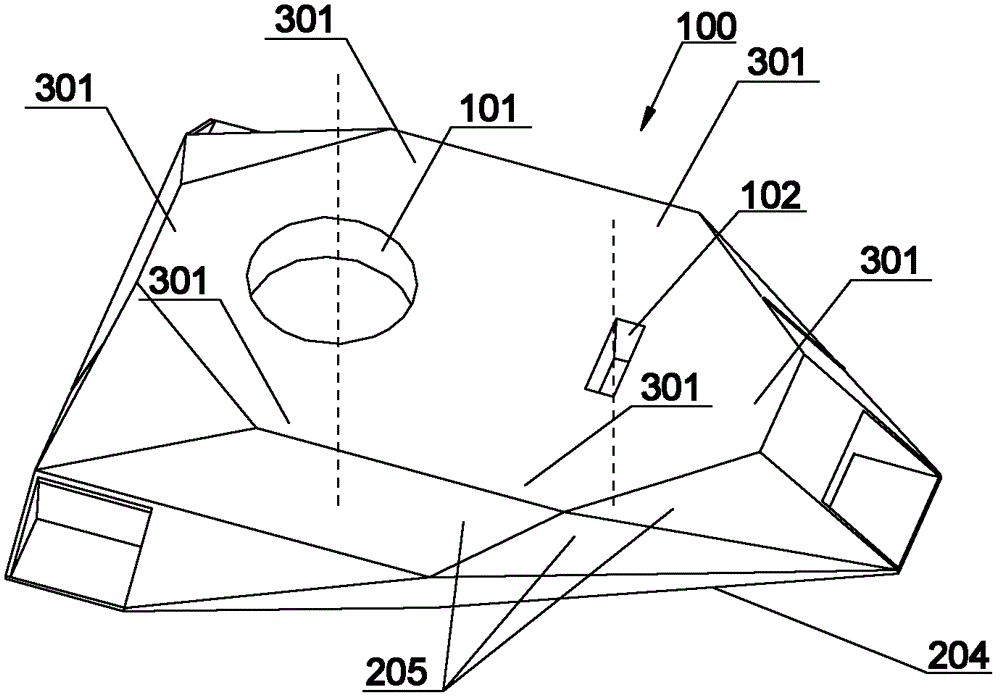

[0041] In order to illustrate the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0042]The polyhedral main substrate of the present invention is used for installing the supporting device, the measuring device and the lens barrel device, and at least one station is provided on the main substrate. Wherein, the outer surface of the main substrate is defined by the polygonal enveloping surface of the installation area of the supporting device, the measuring device, and the lens barrel device, and is a convex polyhedron formed by connecting several other planes according to convex hull rules. In a specific implementation manner, the enumeration that the polyhedral main substrate is a double-station main substrate should not be considered as a limitation of the present invention.

[0043] see figure 1 , figure 2 , fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com