Bifenazate-containing insecticidal composition

An insecticidal composition, the technology of bifenazate, applied in the directions of acaricides, biocides, animal repellents, etc., can solve the problems of ineffectiveness of adult mites, poor persistence, and low lethality, and achieve crop safety. The effect of good sex, good insecticidal effect and low drug cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

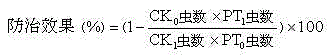

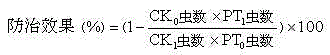

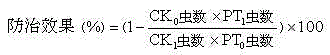

Method used

Image

Examples

Embodiment 1

[0025] Weigh 0.8% bifenazate, 50% fenbutyltin, 3% TERSPERSE 2700 (polycarboxylate, produced by Huntsman, USA), 2% diffusing agent NNO (alkyl naphthalene sulfonate formaldehyde condensate), 3% pull open powder BX (sodium dibutyl naphthalene sulfonate), 2% K-12 (sodium lauryl sulfate), 3% white carbon black, 5% ammonium sulfate, diatomaceous earth added to 100% by weight . 50.8% bifenazate · fenbutatin water dispersible granules were prepared by the above-mentioned raw materials through the conventional method for preparing water-dispersible granules, namely mixing, ultra-micro airflow pulverization, mixing, and granulation.

[0026] In this embodiment, the weight ratio of bifenazate to fenbutatin can be changed between 0.01-200:1, and the total weight composition of the two is still 50.8%, forming a new embodiment.

Embodiment 2

[0028] Weigh 40% bifenazate, 0.3% fenbutyltin, 3% TERSPERSE 2700 (polycarboxylate, produced by Huntsman, USA), 2% diffusing agent NNO (alkyl naphthalene sulfonate formaldehyde condensate), 3% pull open powder BX (sodium dibutyl naphthalene sulfonate), 2% K-12 (sodium lauryl sulfate), 3% white carbon black, 5% ammonium sulfate, diatomaceous earth added to 100% by weight . 40.3% bifenazate · fenbutatin water dispersible granules were prepared by the above-mentioned raw materials through the conventional method for preparing water-dispersible granules, ie mixing, ultra-micro airflow pulverization, mixing, and granulation.

[0029] In this embodiment, the weight ratio of bifenazate to fenbutatin can be changed between 0.01-200:1, and the total weight composition of the two is still 40.3%, forming a new embodiment.

Embodiment 3

[0031] Weigh 30% bifenazate, 30% fenbutyltin, 3% TERSPERSE 2700 (polycarboxylate, produced by Huntsman, USA), 4% diffusing agent NNO (alkyl naphthalene sulfonate formaldehyde condensate), 3% pull open powder BX (sodium dibutyl naphthalene sulfonate), 5% K-12 (sodium lauryl sulfate), 3% white carbon black, 5% ammonium sulfate, diatomaceous earth added to 100% by weight . 60% bifenazate · fenbutatin water dispersible granules are prepared by the conventional method of preparing water dispersible granules from the above raw materials, that is, mixing, ultrafine airflow pulverization, mixing, and granulation.

[0032] In this embodiment, the weight ratio of bifenazate and fenbutatin can be changed between 0.01-200:1, and the total weight content of the two is still 60%, forming a new embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com