Efficient and energy-saving oolong tea refined-baking and aroma-enhancing machine

An oolong tea, energy-saving technology, applied in the field of tea electric baking equipment, can solve the problem that the active ingredients are not easy to accumulate and react

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

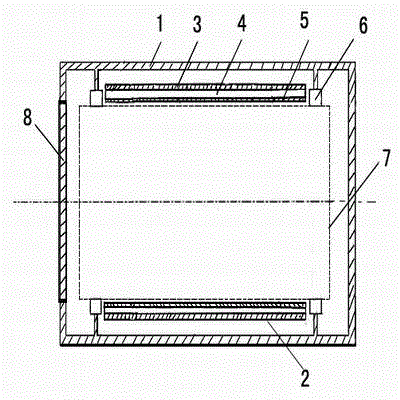

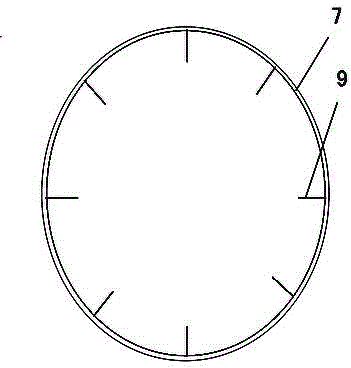

[0018] Describe in detail below with reference to accompanying drawing:

[0019] as attached figure 1 , 2 The technical features of the high-efficiency and energy-saving oolong tea essence roasting and aroma-increasing machine described in the embodiments are: a thermal insulation box (1) a cylindrical electric heater (2) a horizontal device, the inner cavity of which constitutes a baking chamber; supports and The driving mechanism (6) is installed near the two ends of the cylindrical electric heater (2), and is used to support and drive the cylindrical tea box (7) to rotate. The wall of the cylindrical tea box (7) is provided with ventilation holes, and there are several tea leaf guide plates (9) inside it. The structure of the cylindrical electric heater (2) is as follows: the inner electric insulation layer (5), the middle electric heating body (4), and the outer heat insulation layer (3) are arranged in sequence, and power supply electrodes are installed at both en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com