Serum separation gel and preparation method thereof

A technology of serum separation gel and polyacrylate, which is applied in the field of serum separation gel, can solve the problems of large gap in quality of serum separation gel, stability of domestic separation gel, poor adhesion and thixotropy, and poor resistance to gamma-rays, etc. , to achieve the effects of easy control of the production process, strong cohesion, and stable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A preparation method of serum separating gel, comprising the steps of:

[0026] (1) Add toluene, 2-mercaptoethanol, a 50% by mass mixture of butyl acrylate and ethyl methacrylate, and 0.6 parts of BPO into the flask;

[0027] (2) Stir and heat up. When the temperature reaches 85°C to 90°C, drop the remaining monomer mixture containing 0.6 parts of BPO, butyl acrylate and ethyl methacrylate into the reaction flask from the dropping funnel and keep the temperature 85 ℃ ~ 90 ℃, drop the monomer within 3 hours;

[0028] (3) After continuing to react for 1 hour, lower the temperature to below 70°C to obtain an acrylate copolymer solution;

[0029] (4) The solution was distilled under reduced pressure for 2 hours to remove the solvent toluene and unreacted monomers to obtain a polyacrylate solution;

[0030] (5) Add 5-10 parts of hydrophobic fumed silica and 0-10 parts of diluent DOP to the polyacrylate solution, and stir evenly;

[0031] (6) Vacuum degassing to obtain the...

Embodiment 1

[0033] The invention provides a serum separating gel, which is prepared from the following raw materials in parts by mass:

[0034] Polyacrylate resin 100 parts

[0035] Thixotropic agent hydrophobic fumed silica 3 parts

[0036] The polyacrylate resin described therein is prepared according to the following ratio:

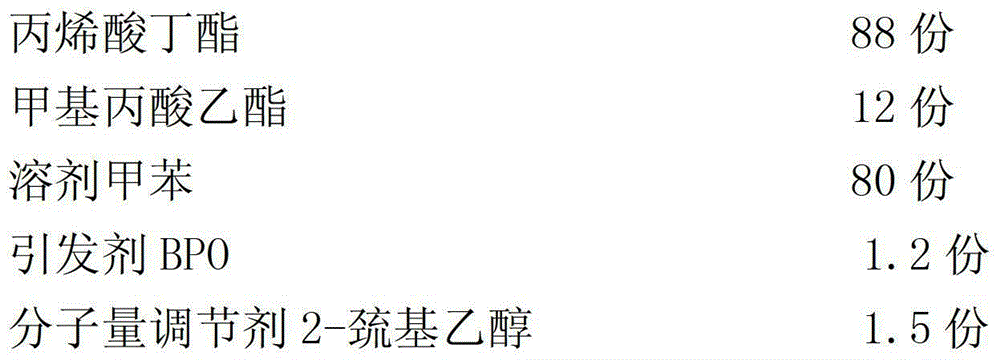

[0037]

[0038] In the polyacrylate serum separation gel, the main performance of the serum separation gel is expressed by polyacrylate. Solution polymerized polyacrylate has the characteristics of low molecular weight, adjustable molecular weight, low viscosity, high monomer conversion rate, and easy control of the preparation process; as the main material, polyacrylate can be copolymerized by monomers of different types and dosage ratios. Its density is close to that of serum separation gel, which just meets the density requirements of serum separation gel; polyacrylate has a large polarity and large intermolecular cohesion energy, and can form a uniform an...

Embodiment 2

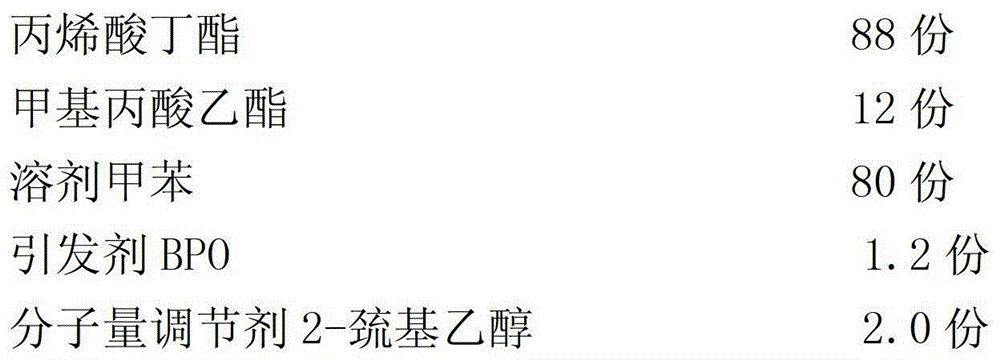

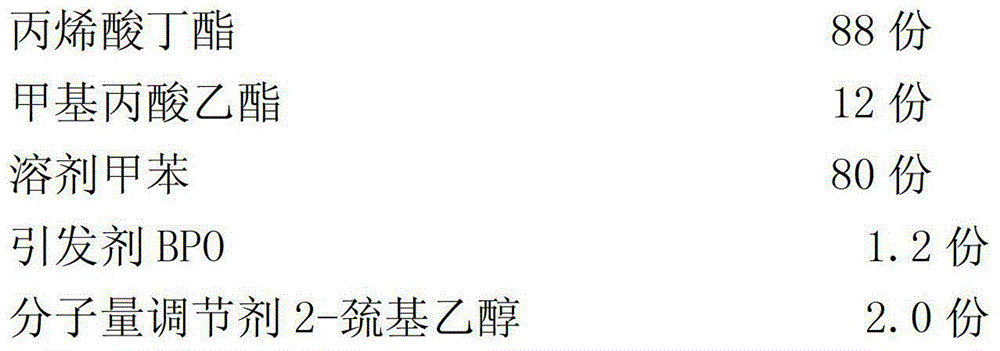

[0041] A preparation method of serum separating gel, comprising the steps of:

[0042] (1) A mixture of toluene, 2-mercaptoethanol, 50% mass ratio of butyl acrylate and ethyl methacrylate and 0.6 parts of BPO are added to the flask;

[0043] (2) Stir and heat up. When the temperature reaches 85°C, add the remaining monomer mixture of butyl acrylate and ethyl methacrylate containing 0.6 parts of BPO dropwise from the dropping funnel to the reaction flask, keeping the temperature at 85°C. Drop the monomer within 3 hours;

[0044] (3) After continuing to react for 1 hour, the temperature was lowered to below 70° C. to obtain an acrylate copolymer solution;

[0045] (4) The solution is distilled under reduced pressure for 2 h, and the solvent toluene and unreacted monomers are removed to obtain a polyacrylate solution;

[0046] (5) Add 5 parts of hydrophobic fumed silica to the polyacrylate solution, and stir evenly;

[0047] (6) Vacuum degassing to obtain the product serum sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com