Method for fusing enriched precious metal from spent automotive catalyst

A technology of automotive catalysts and precious metals, applied in the direction of improving process efficiency, etc., can solve the problems of large waste water, low recovery rate, etc., and achieve the effects of convenient process operation, low production cost, and small dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

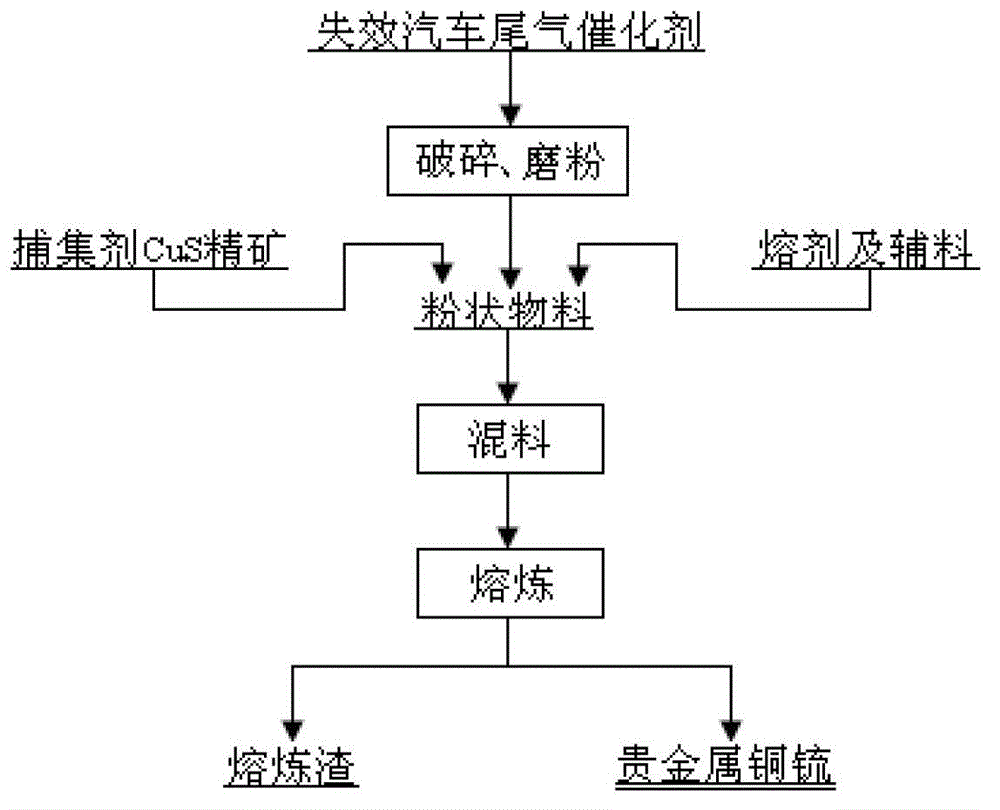

Method used

Image

Examples

Embodiment 1

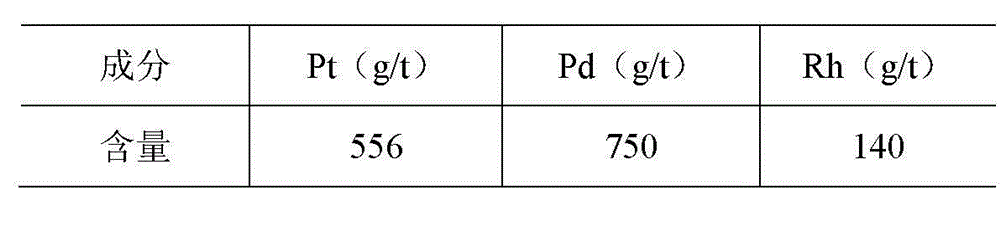

[0021] Take the block-shaped invalid automobile exhaust catalyst and crush it, grind it to a powder with a particle size of 30 mesh, then weigh 500g of the ground material, add 50g of copper sulfide ore, add 15g of calcium oxide, and add SiO 2 10g.

[0022] Mix the above materials evenly, put them into a graphite crucible, and keep the temperature at 1250°C for 4 hours in a high-temperature resistance furnace. After the smelting is completed, the crucible is taken out to cool naturally, and then the slag and the metal phase are separated to obtain 23 grams of the precious metal copper matte phase and 512 grams of the smelting slag. The content is 2.8g / t.

Embodiment 2

[0024] Take the block-shaped invalid automobile exhaust catalyst and crush it, grind it to a powder with a particle size of 200 mesh, then weigh 500g of the ground material, add 100g of copper sulfide ore, add 30g of calcium oxide, and add SiO 2 20g.

[0025] Mix the above materials evenly, put them into a graphite crucible, and keep the temperature at 1450°C for 2 hours in a high-temperature resistance furnace. After the smelting was completed, the crucible was taken out to cool naturally, and then the slag and the metal phase were separated to obtain 51 grams of the precious metal copper matte phase and 536 grams of the smelting slag. After the slag sample was crushed and ground, the sample was sent to analyze the content of the precious metal in the slag. The total amount of platinum, palladium and rhodium was The content is 1.3g / t.

Embodiment 3

[0027] Take the block-shaped invalid automobile exhaust catalyst and crush it, grind it to a powder with a particle size of 200 mesh, then weigh 500g of the ground material, add 125g of copper sulfide ore, add 30g of calcium oxide, and add SiO 2 20g.

[0028] Mix the above materials evenly, put them into a graphite crucible, and keep the temperature at 1350°C for 1 hour in a high-temperature resistance furnace. After the smelting is completed, the crucible is taken out to cool naturally, and then the slag and the metal phase are separated to obtain 63 grams of the precious metal copper matte phase and 515 grams of the smelting slag. After the slag sample is broken and ground, the sample is sent to analyze the content of the precious metal in the slag, platinum palladium rhodium The total content is 1.8g / t.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com