Intelligent drying control method for washing machine

A control method and washing machine technology, which are applied in the control device, washing device, textile and paper making of washing machine, etc., can solve the problems of the washing machine's drainage speed can not keep up, the motor loses the dehydration time, the dehydration difficulty and the dehydration effect, etc., so as to reduce the dehydration. Time and loss of motor, reduction of operating time, effect of saving electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

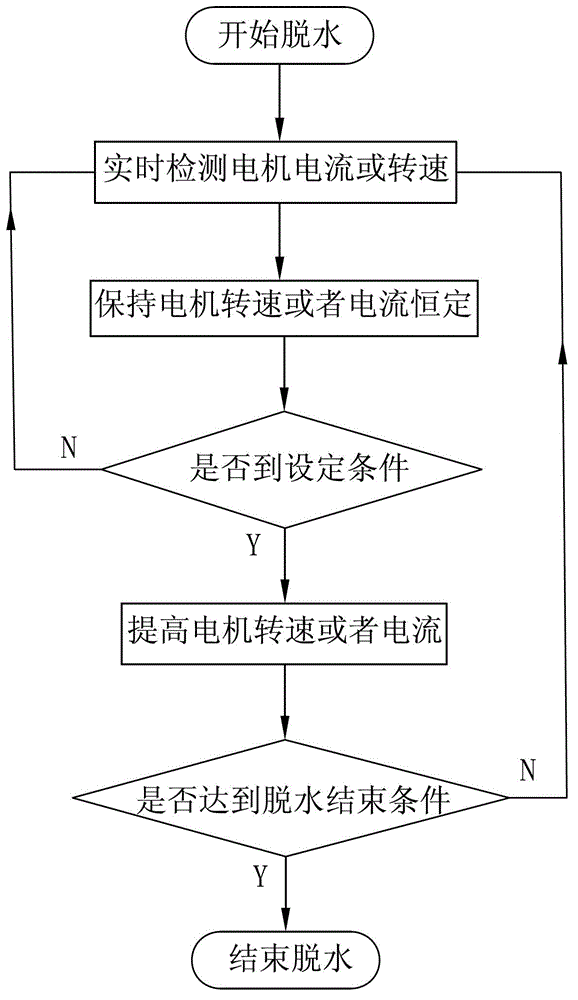

Embodiment 1

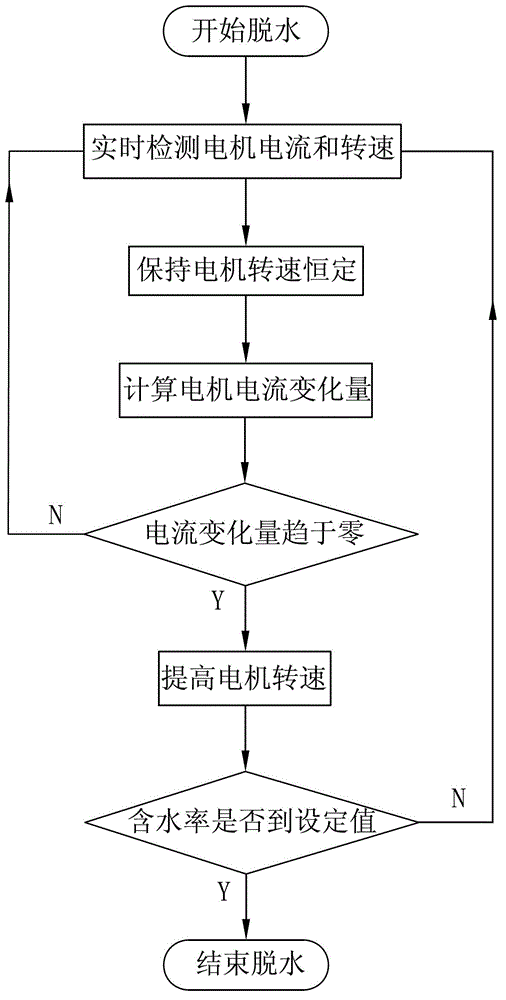

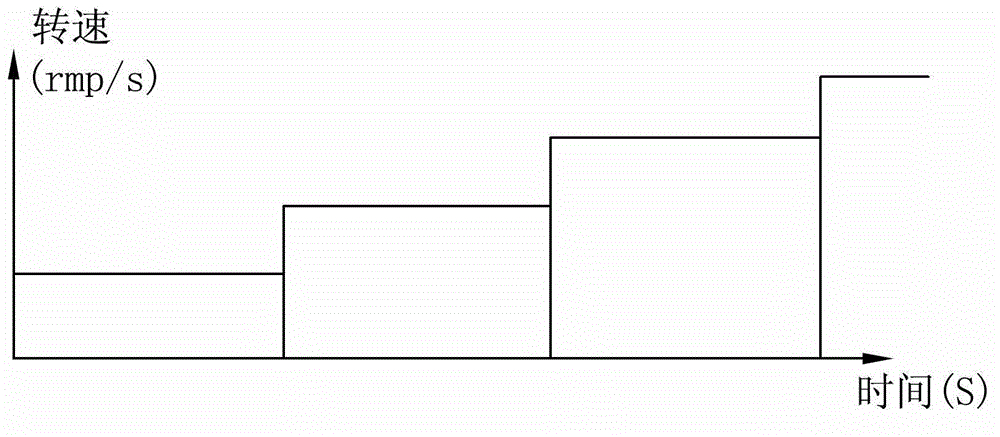

[0040] see figure 2 , the flow chart of the dehydration control method, which further elaborates on increasing the motor speed step by step. After the dehydration starts, the control system first detects the current and speed of the motor in real time, and then keeps the motor speed constant. Under the condition that the motor speed is constant Next, calculate the variation of the motor current. When the variation of the motor current tends to zero, the motor speed is quantitatively increased to enter the next stage, and whether the set dehydration rate of the clothes is reached is used as the dehydration end condition. In the case of ensuring the dehydration effect, the dehydration end condition can be one of the following conditions: the set total dehydration time, the set moisture content of the clothes, the set number of motor current increments, the set motor speed Increment times. Among the enumerated dehydration end conditions, setting the moisture content of the clot...

Embodiment 2

[0045] Compared with Embodiment 1, the principle adopted in this embodiment is the same, and also in the dehydration process, the control system detects the current and speed of the motor in real time, and also adopts a step-by-step increment method, but if Image 6 As shown, in this embodiment, the motor current remains constant in the same stage, and the condition for increasing the motor current is that the variation of the motor speed tends to zero in the same stage. Formula 1 and formula 2 are equally applicable to this embodiment, according to formula 1 and formula 2, and referring to Figure 7 with Figure 8 , the motor speed always increases during the whole dehydration process. Since the motor current remains constant in the same stage, it means that the output power of the motor is also constant, so when the motor speed reaches a certain value under the motor current, the variation will tend to If it is less than zero, it means that the dehydration effect is already...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com