Manufacturing method of ebenaceae leaf tea

A production method and technology for persimmon leaf tea, applied in the direction of tea substitutes and other directions, can solve the problems affecting the development of persimmon industry, serious green smell and sour taste of persimmon leaf tea, and achieve rich varieties, sweet and pure aroma, and controllable process parameters. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

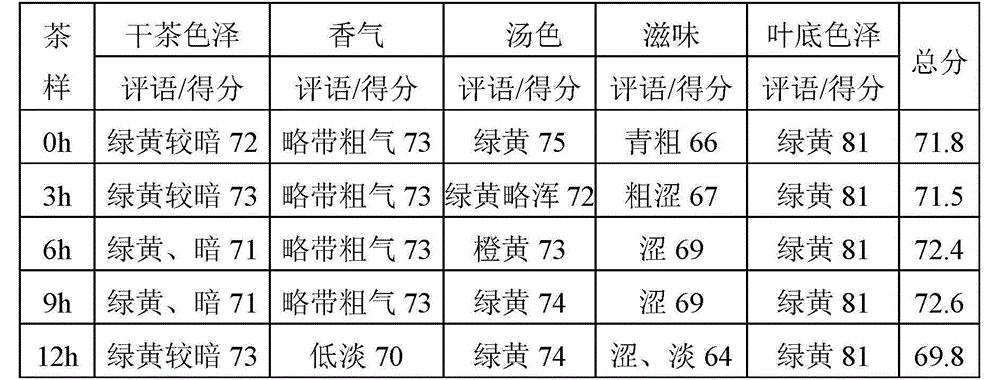

[0022] Embodiment 1 Determination of withering time

[0023] The fresh leaves were harvested and spread in the withering tank for 3 hours, 6 hours, 9 hours, and 12 hours respectively. The sensory quality of persimmon leaf tea under each treatment condition is shown in Table 1. It can be seen that after the fresh leaves are picked and withered, the rough green taste is weakened and the quality is improved. However, after the withering time exceeds 9 hours, the taste of the tea soup becomes weak, with little sweetness and weak aroma.

[0024] Quality component analysis showed that withering time had no significant effect on polyphenols, soluble sugars and flavonoids, but had a very significant effect on amino acids, and the amino acid content was the highest when fresh leaves were withered for 3-6 hours. As the withering time prolongs, the content of vitamin C gradually decreases.

[0025] Table 1 Sensory quality of persimmon leaf tea treated with different withering time

[0...

Embodiment 2

[0032] Embodiment 2 Determination of Shaking Green Process Parameters

[0033] 1. Determination of the number of shakes

[0034] The number of shaking times has a great influence on the sensory quality of persimmon leaf tea. The results in Table 3 show that with the increase of shaking times, the rough and old smell in persimmon leaf tea will be removed, and the taste will also change and become fresher. Sweet and refreshing, but no longer has a rough, sour, astringent taste. The color of the soup also gradually changed, becoming orange and bright.

[0035] The results of the influence of shaking times on the main chemical components of persimmon leaf tea such as polyphenols, soluble sugars, amino acids and flavonoids are shown in Table 4. The content of quality components has little effect, but it has a greater impact on vitamin C, and the content of vitamin C has a downward trend in the process of shaking green.

[0036] Table 3 Sensory quality of persimmon leaf tea tre...

Embodiment 3

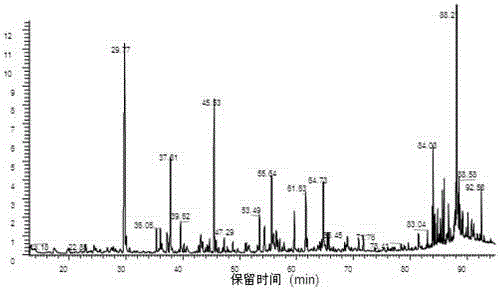

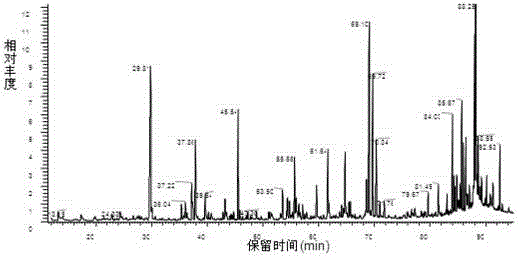

[0066] Embodiment 3 The comparison of technology of the present invention and traditional technology

[0067] The process of the present invention: picking fresh young leaves, fresh green leaves, leaves free of disease and insects, and operating according to the technological process of withering, shaking greens, killing greens, kneading (kneading and cutting), drying, and enhancing fragrance. Wither in the withering trough for 6 hours, put the withered leaves in a shaker (Fujian Jiayou Tea Machine Factory) and shake the green 3 times. The setting time is respectively: 1.5h, 2h, 3h. The standing temperature is about 25°C and the humidity is about 70%. After shaken, the 6CST-40 drum continuous de-greening machine (produced by Zhejiang Lvfeng Machinery Co., Ltd.) is used for de-enzyming at a temperature of about 120°C. Then, it is aired to regain moisture, kneaded (kneaded and cut) to shape, and kneaded for about 30 minutes. Stir-fry in a frying machine (product of Zhejiang Lv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com