Preparation method of anti-osteoporotic micro/nano biomimetic coating of bone implant

An anti-osteoporosis and implant technology, applied in coating, metal material coating process, ion implantation plating, etc., can solve the problems of insufficient bonding strength, high exfoliation rate, no anti-osteoporosis, etc., and achieve deposition The effect of fast speed, high bonding strength and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention adopts the magnetron sputtering method to prepare the surface treatment process of strontium-loaded anti-osteoporosis micro / nano biomimetic coating with high binding strength on the surface of the implant, comprising the following steps:

[0019] A. Decontaminate the surface of the implant;

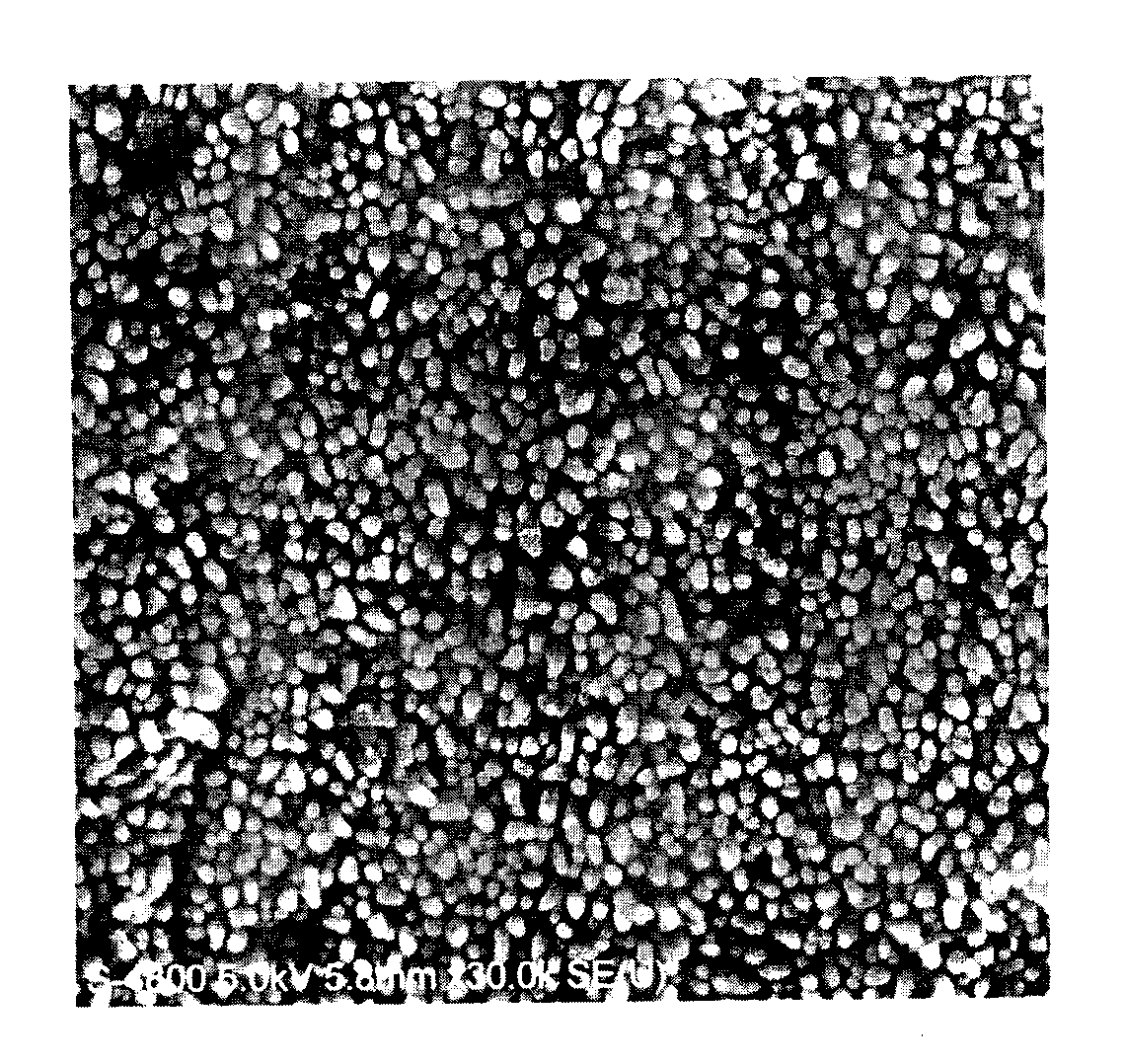

[0020] B. The surface of the implant is acid-etched with a hydrofluoric acid solution with a concentration of 2%, so that micron pits of 2-5 μm are formed on the surface of the implant;

[0021] C. Then rinse the acid-etched bone implants in sequence with distilled water - ultrasonic cleaning with acetone - ultrasonic cleaning with absolute ethanol - ultrasonic cleaning with distilled water;

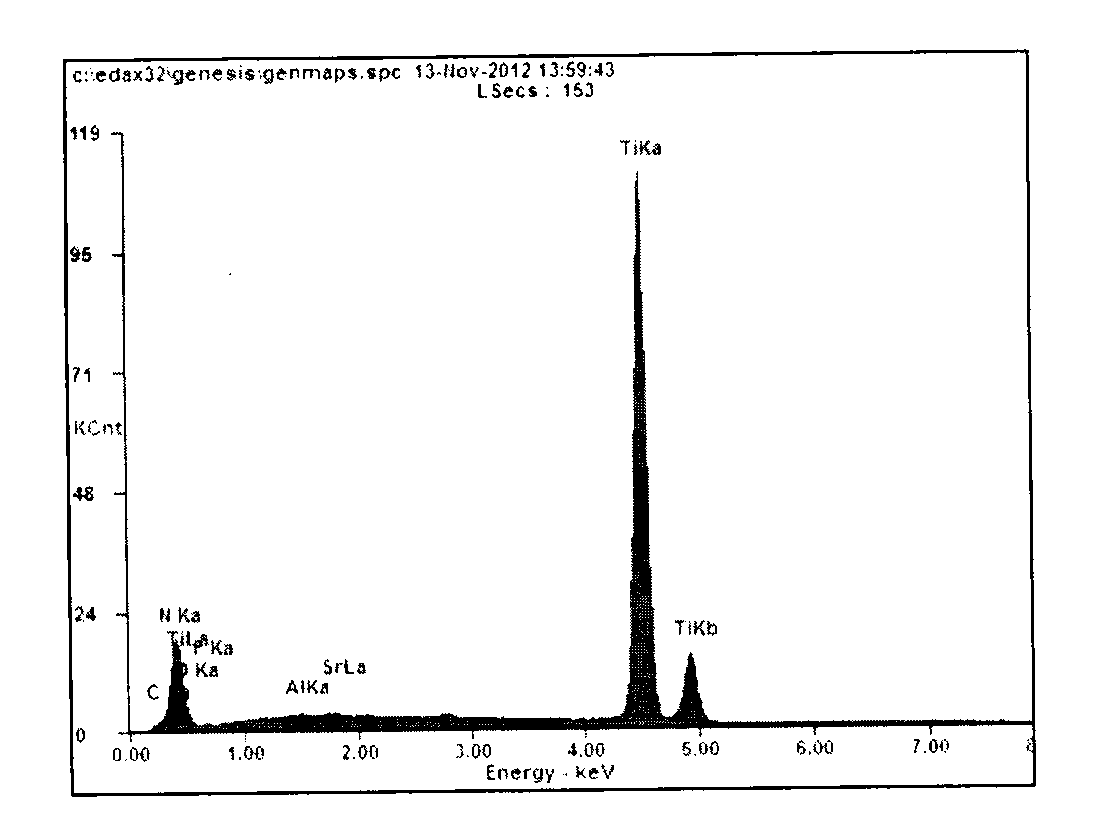

[0022] D. Using strontium titanate as the target material, the acid-etched bone implant as the substrate, and using radio frequency magnetron sputtering technology to prepare high bonding strength, strontium-loaded anti-osteoporosis effect on the surface of the implant s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com