Production method of cassava starch

A production method, cassava starch technology, applied in the direction of sustainable manufacturing/processing, climate sustainability, chemical industry, etc., can solve the problems of large power consumption and water consumption, which is not conducive to saving power, water sources and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

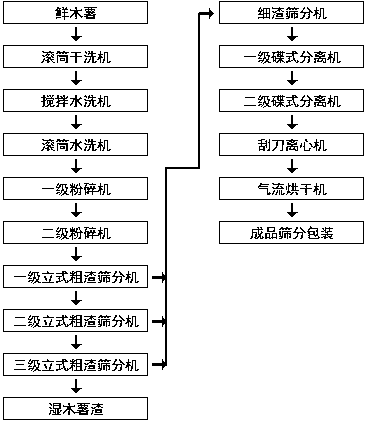

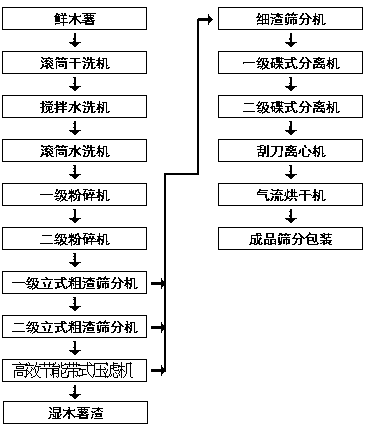

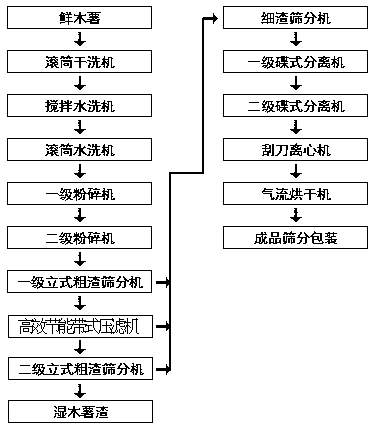

[0030] figure 1 Shown is the process flow diagram of the existing tapioca starch production technology; as can be seen from the figure, the process flow of the existing tapioca starch production technology is usually: cassava→washing and peeling with a drum dry cleaning machine and agitating washing machine→using two-stage pulverization The crushed cassava dregs pulp is separated and extracted with a three-stage screening machine → the pulp part is dehydrated and dried by a fine slag screening machine and a two-stage disc separator scraper centrifuge → starch, and then screened and packaged as a finished product . Among them, "separation of crushed cassava residue pulp with three-stage screening machine" generally adopts vertical screening machine. The minimum motor in each vertical screening machine is 15KW. A large amount of water can be injected to dilute and dec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com