Bimaleimide resin toughening modifiers and preparation method thereof

A technology of bismaleimide and toughening modifier, which is applied in the field of bismaleimide (BDM) preparation, can solve problems such as unusable, difficult process control, and difficult precise control, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

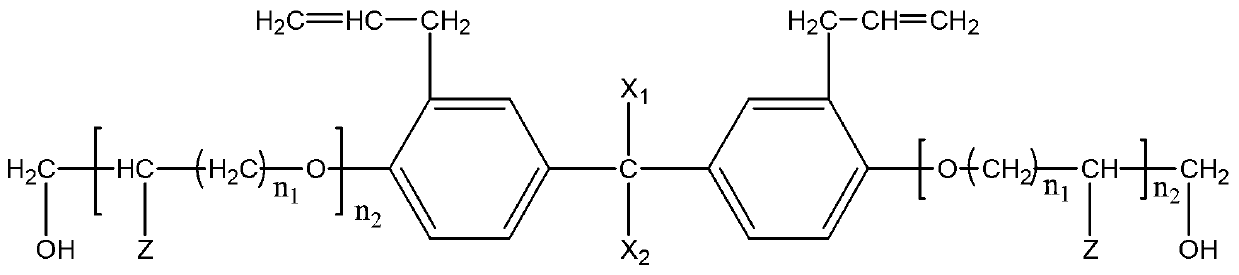

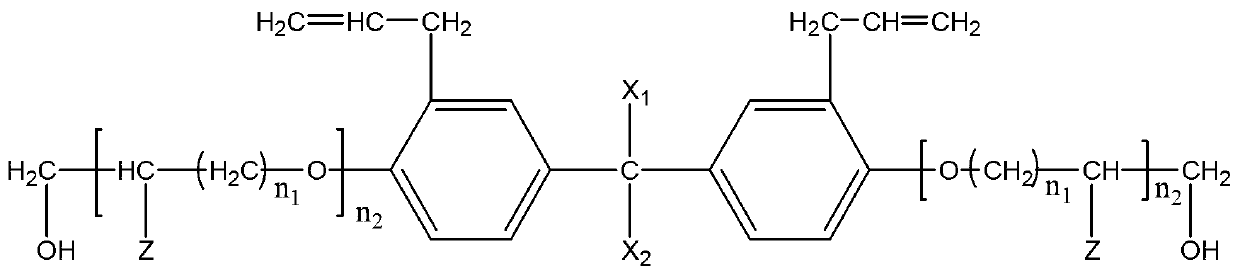

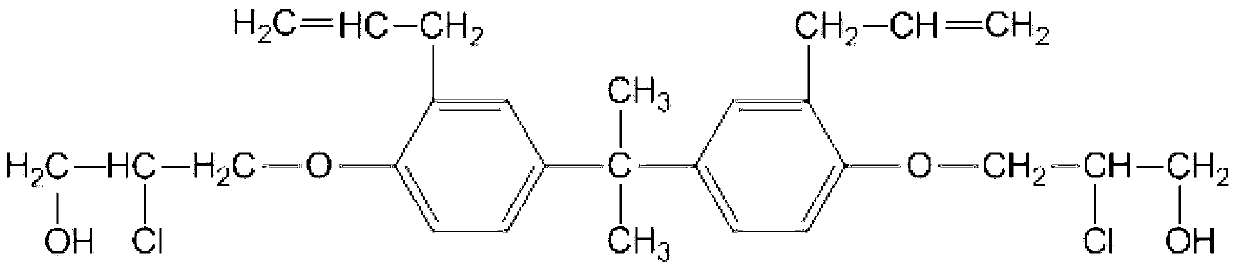

[0023] The toughening modifier of a kind of bismaleimide resin prepared by the present embodiment, its general structural formula is expressed as:

[0024]

[0025] The preparation method of the present embodiment comprises the following steps:

[0026] Step 1: Add 20 grams of diallyl bisphenol A and 48.1 grams of epichlorohydrin into a three-necked flask equipped with a stirring and temperature control device, stir at 65°C for 15 minutes, cool down to below 60°C, and dissolve 6.5 grams of NaOH The solid was added to the reaction system twice in 50 minutes; the temperature was raised, and the reaction was carried out at 75°C for 4 hours; deionized water was added to dissolve the generated salt, and the liquid was separated with a separatory funnel, and the reaction solution in the lower layer was removed, and the remaining rings of the reaction were evaporated. Oxychloropropane; 30 g of toluene was added to the obtained crude product, washed with deionized water until the w...

Embodiment 2

[0031] The toughening modifier of a kind of bismaleimide resin prepared by the present embodiment, its general structural formula is expressed as:

[0032]

[0033] The preparation method of the present embodiment comprises the following steps:

[0034] Step 1: Add 20 grams of diallyl bisphenol A and 60.1 grams of epichlorohydrin into a three-necked flask equipped with a stirring and temperature control device, stir at 65°C for 10 minutes, cool down to below 60°C, and dissolve 6.0 grams of NaOH The solid was added to the reaction system in 3 times over 60 minutes; the temperature was raised, and the reaction was carried out at 110°C for 3 hours; deionized water was added to dissolve the generated salt, and the liquid was separated with a separatory funnel, and the reaction solution in the lower layer was removed, and the remaining rings of the reaction were evaporated. Oxychloropropane; add 35g toluene to the obtained crude product, wash with deionized water until the water...

Embodiment 3

[0039] The toughening modifier of a kind of bismaleimide resin prepared by the present embodiment, its general structural formula is expressed as:

[0040]

[0041] The preparation method of the present embodiment comprises the following steps:

[0042] Add 20 grams of diallyl bisphenol A and 55.2 grams of chloroethanol into a three-necked flask equipped with a stirring and temperature control device, and stir at 65°C for 10 minutes; cool down to below 60°C, and add 4.0 grams of NaOH solid to the reaction system Medium; raise the temperature and react at 110°C for 4 hours; add deionized water to dissolve the generated salt, separate the liquid with a separatory funnel, take the lower layer of the reaction solution, and distill off the remaining chlorohydrin; add to the obtained crude product An appropriate amount of toluene is washed with deionized water until the water phase is neutral, and the toluene is evaporated to obtain 20.4 grams of toughening modifier A of bismalei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com