Black organic silicon heat resisting paint and preparation method thereof

A black organic, heat-resistant paint technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of low hardness and poor flame resistance, and achieve the effect of improving the strength of the coating film, improving the water resistance, and improving the high temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

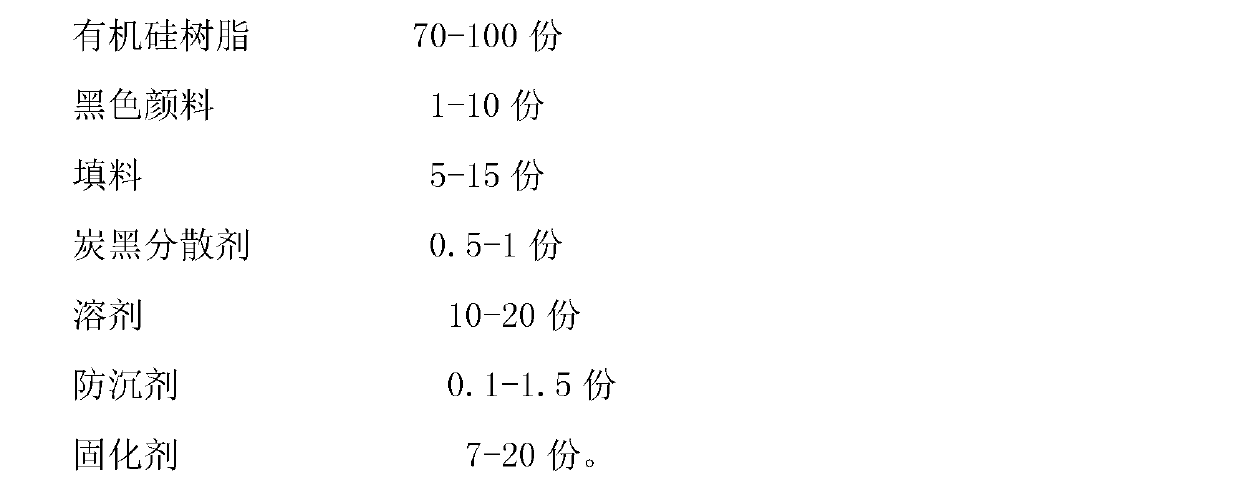

[0027] A kind of black organosilicon heat-resistant paint, is made up of following raw material by weight:

[0028]

[0029] Preparation:

[0030] (1) According to the proportion, first add the black pigment and carbon black dispersant into the solvent for pre-soaking for 48 hours to obtain the modified black pigment;

[0031] (2) Mix and stir the modified black pigment in (1) with silicone resin, filler, anti-sedimentation agent, and solvent;

[0032] (3) Put the uniformly mixed material in (2) into a sand mill for grinding for 20 minutes, so that the particle size of the material is 28 μm;

[0033] (4) Add a curing agent to the material in (3) and mix to obtain a black silicone heat-resistant paint.

Embodiment 2

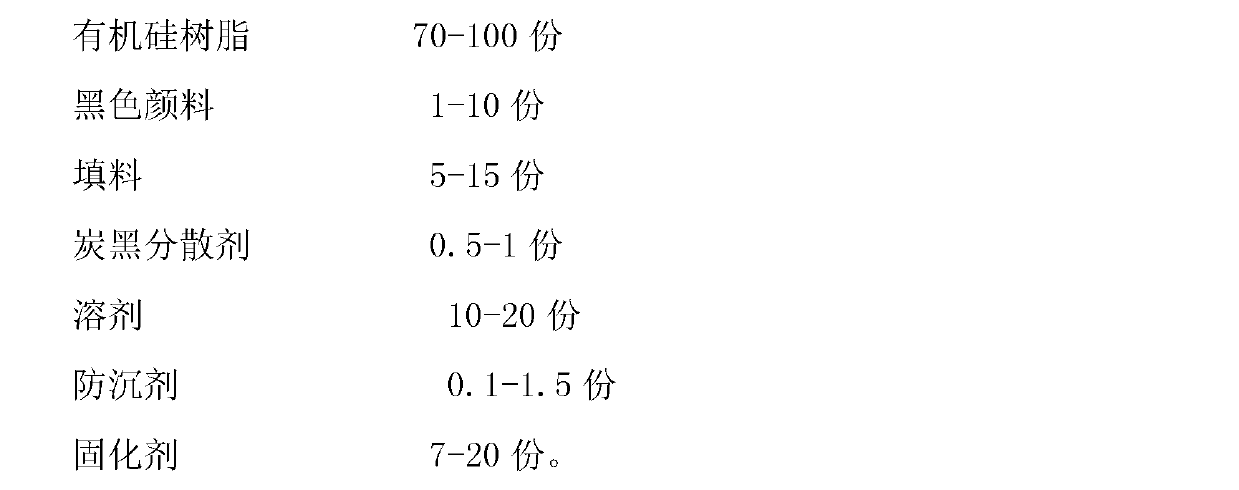

[0035] A kind of black organosilicon heat-resistant paint, is made up of following raw material by weight:

[0036]

[0037] Preparation:

[0038] (1) According to the proportion, first add the black pigment and carbon black dispersant to the solvent for pre-soaking for 50 hours to obtain the modified black pigment;

[0039] (2) Mix and stir the modified black pigment in (1) with silicone resin, filler, anti-sedimentation agent, and solvent;

[0040] (3) Put the homogeneously mixed material in (2) into a sand mill for grinding for 25 minutes, so that the particle size of the material is 30 μm;

[0041] (4) Add a curing agent to the material in (3) and mix to obtain a black silicone heat-resistant paint.

Embodiment 3

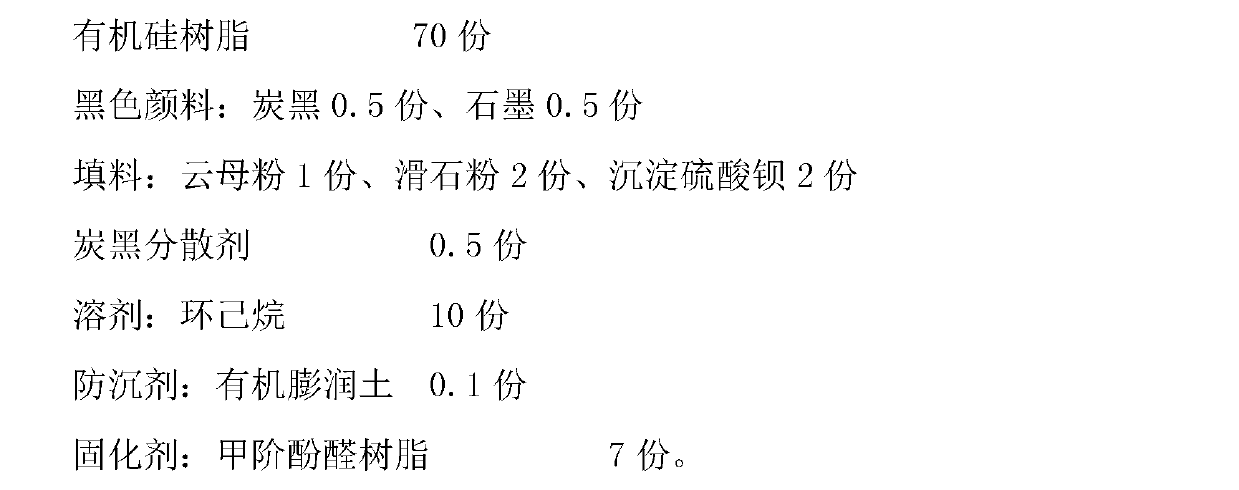

[0043] A kind of black organosilicon heat-resistant paint, is made up of following raw material by weight:

[0044]

[0045]

[0046] Preparation:

[0047] (1) According to the proportion, first add the black pigment and carbon black dispersant into the solvent for pre-soaking for 48 hours to obtain the modified black pigment;

[0048] (2) Mix and stir the modified black pigment in (1) with silicone resin, filler, anti-sedimentation agent, and solvent;

[0049] (3) Put the uniformly mixed material in (2) into a sand mill for grinding for 30 minutes, so that the particle size of the material is 30 μm;

[0050] (4) Add a curing agent to the material in (3) and mix to obtain a black silicone heat-resistant paint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com