Stove fuel gas on-off control method and gas furnace

A technology of on-off control and gas furnace, which is applied in the field of gas on-off control and gas furnace, can solve the problems of shortened service life of accessories, high failure rate, undurable waterproof and oil-proof, etc., and achieves optimized waterproof and oil-draining technology , Eliminate potential safety hazards, and facilitate disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

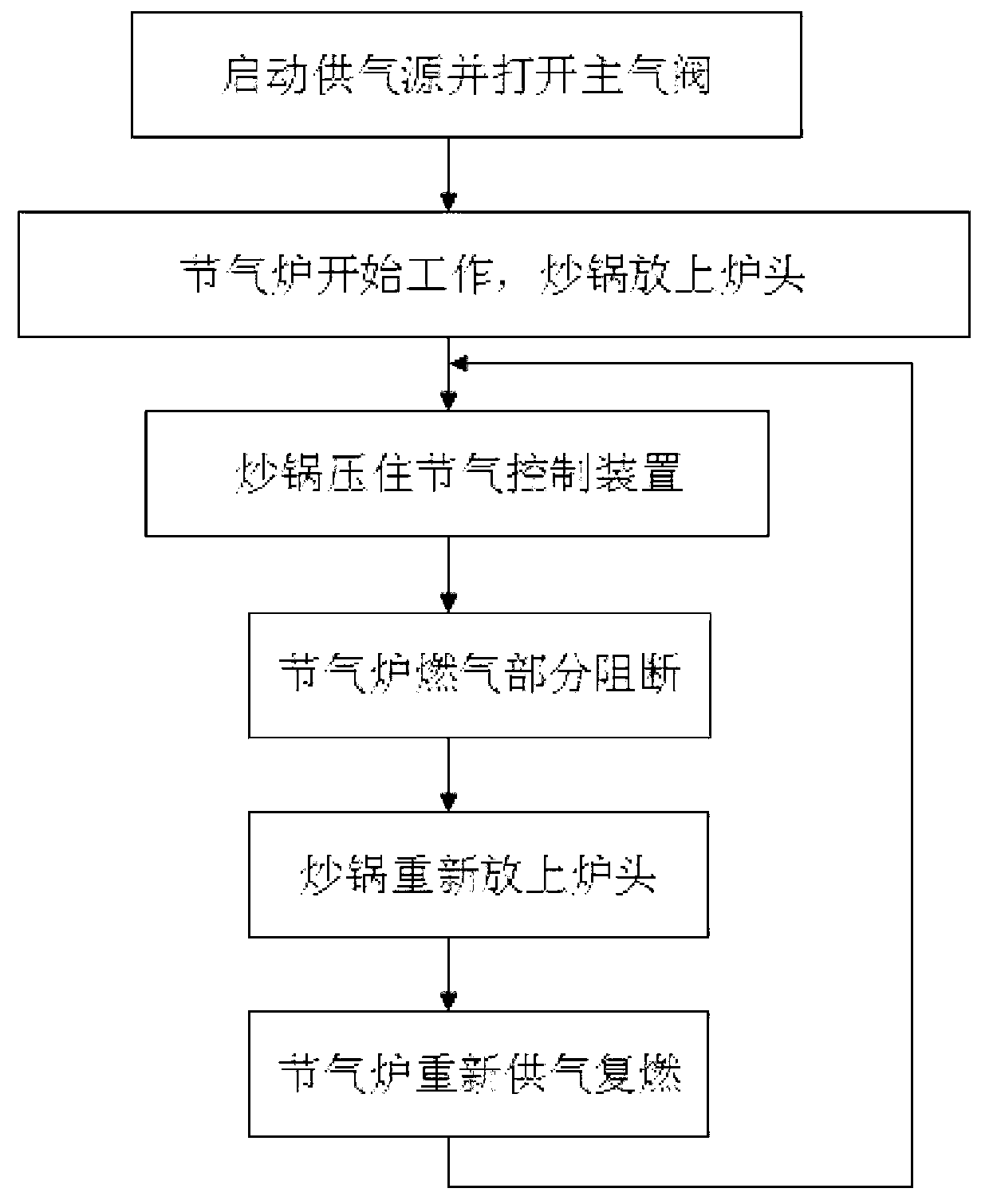

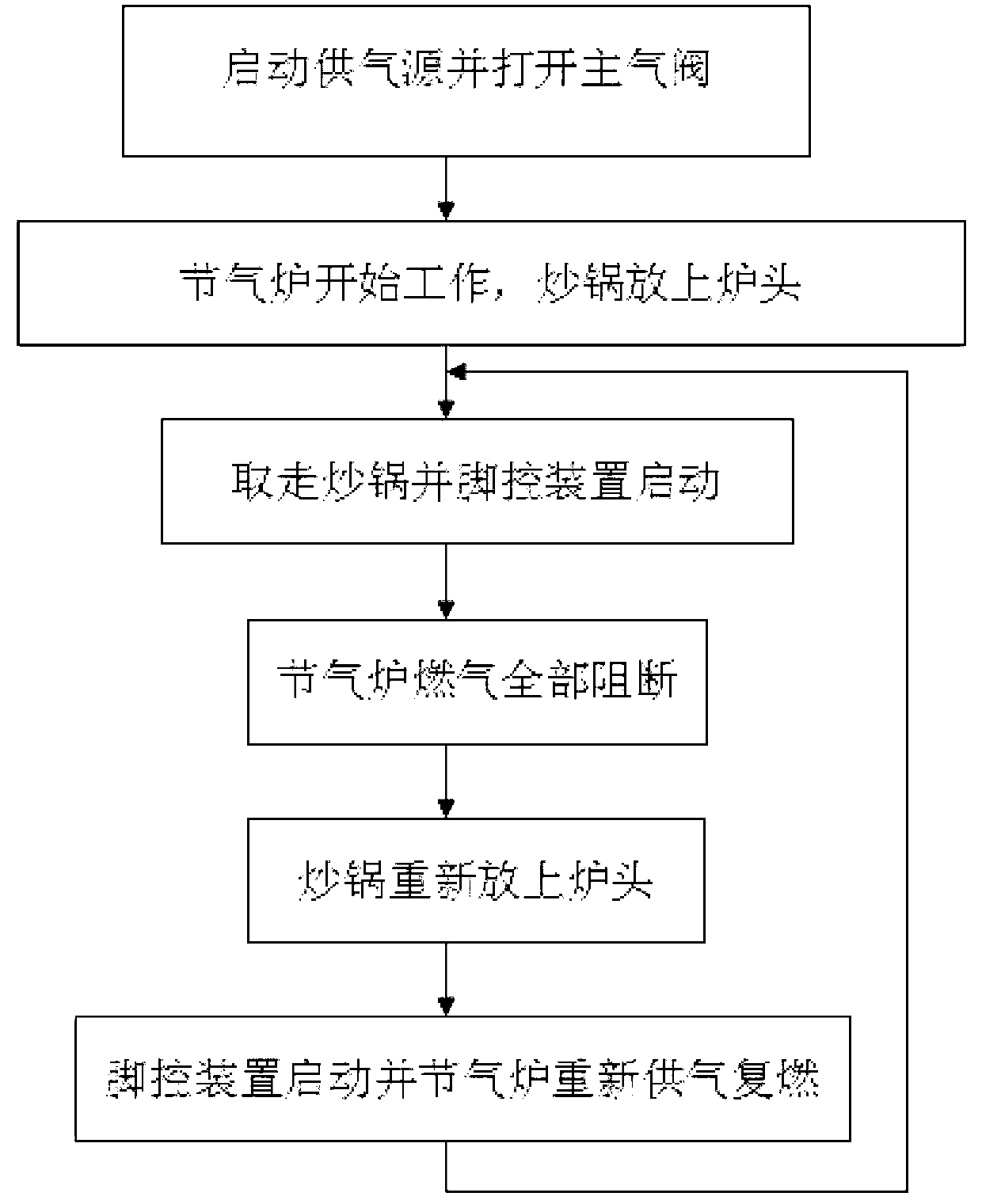

[0035] Such as figure 1 , figure 2 and Figure 4 As shown, the stove gas on-off control method in this embodiment includes the following steps:

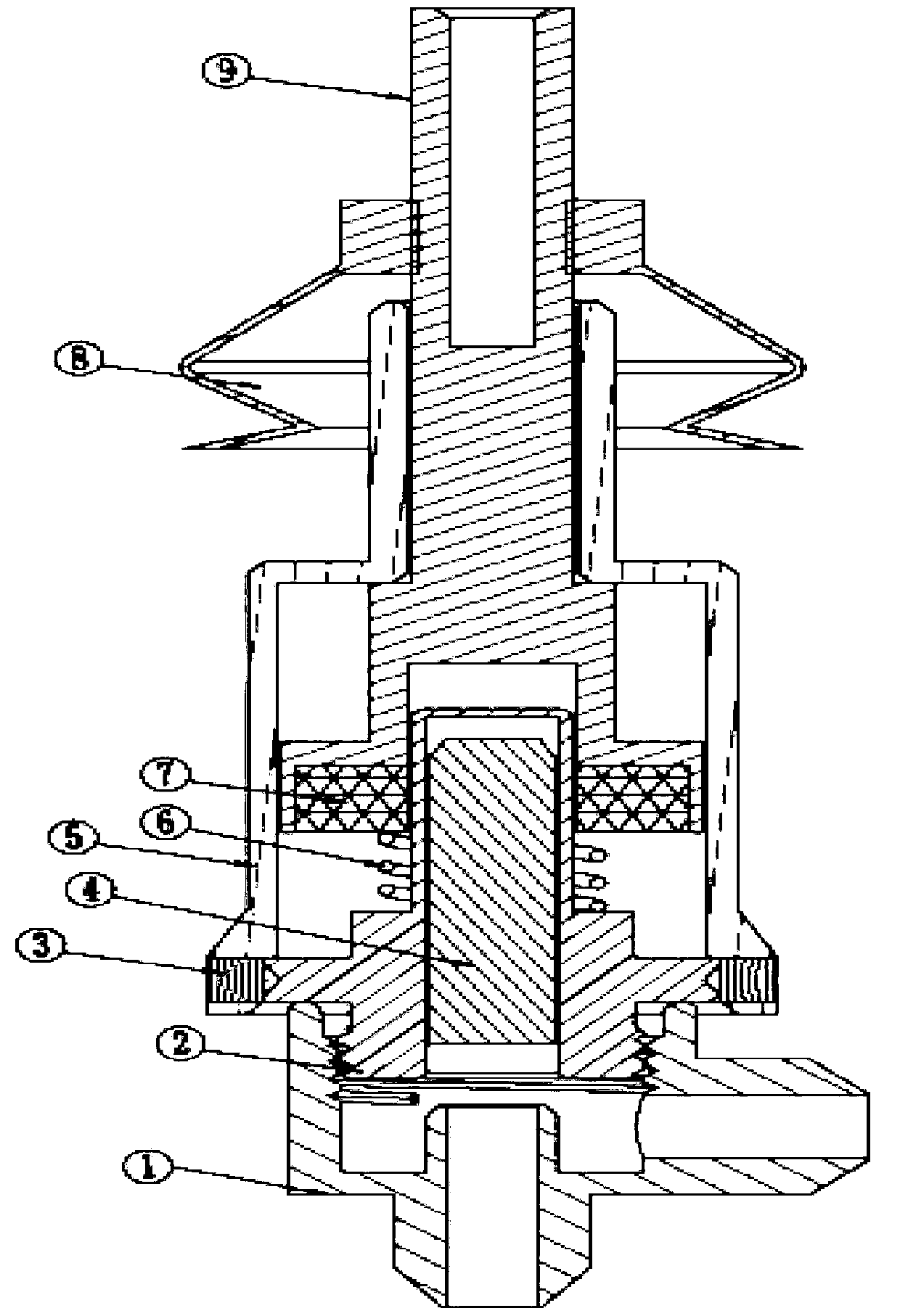

[0036] (1) Install a gas furnace, which is composed of a workbench and an air intake device. The workbench is provided with one or more sets of burners 11; the gas furnace is a single-station or multi-station frying furnace , the air intake devices are respectively connected to the burner heads 11 of different stations, and independently complete the gas on-off control of the burner heads 11, and the air intake devices are externally connected to a gas supply source to form a complete gas supply system.

[0037] (2) The air intake device is composed of a gas transmission channel 13, a gas pipe interface, a main gas valve 12 and an air-saving control device 1. The air-saving control device 1 is composed of a combined air control unit and an air valve; the air intake device According to the function setting, it includes firepower c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com