Pneumatic drier with tail gas waste heat recycling function

A technology of airflow dryer and waste heat recovery, applied in dryers, drying gas layout, drying and other directions, can solve problems such as heat energy waste, and achieve the effects of reducing waste, good low temperature performance, good economic benefits and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

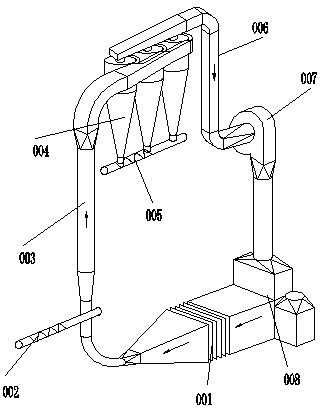

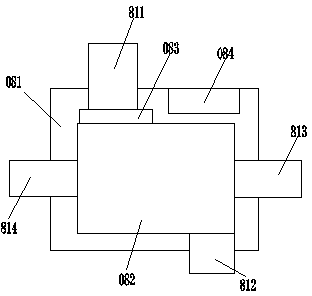

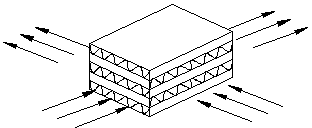

[0014] An airflow dryer capable of recovering waste heat from tail gas, comprising sequentially connected air heat exchanger 001, feed system 002, drying pipeline 003, cyclone separator 004, discharge screw conveyor 005 and tail gas pipeline 006, tail gas The air pipeline 006 passes through the fan 007, and the pipeline is connected to the waste heat recovery device 008. The waste heat recovery device 008 includes a casing 081 and a heat exchanger 082 arranged in the casing 081. The casing 081 is provided with an exhaust gas inlet and outlet (811 , 812) and air inlets and outlets (813, 814), the air outlets (814) are connected to the air heat exchanger 001 through pipes. The exhaust air inlet 811 is provided with an air filter 083 . A cleaning system 084 is additionally provided in the casing of the waste heat recovery device 008 . The heat exchanger 082 is a plate-fin heat exchanger.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com