Long-distance large-range optical fiber strain generating device and generating method

An optical fiber strain and generating device technology, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of short strain generation length, large strain value error, small strain range, etc. length, overcoming the effect of lower precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

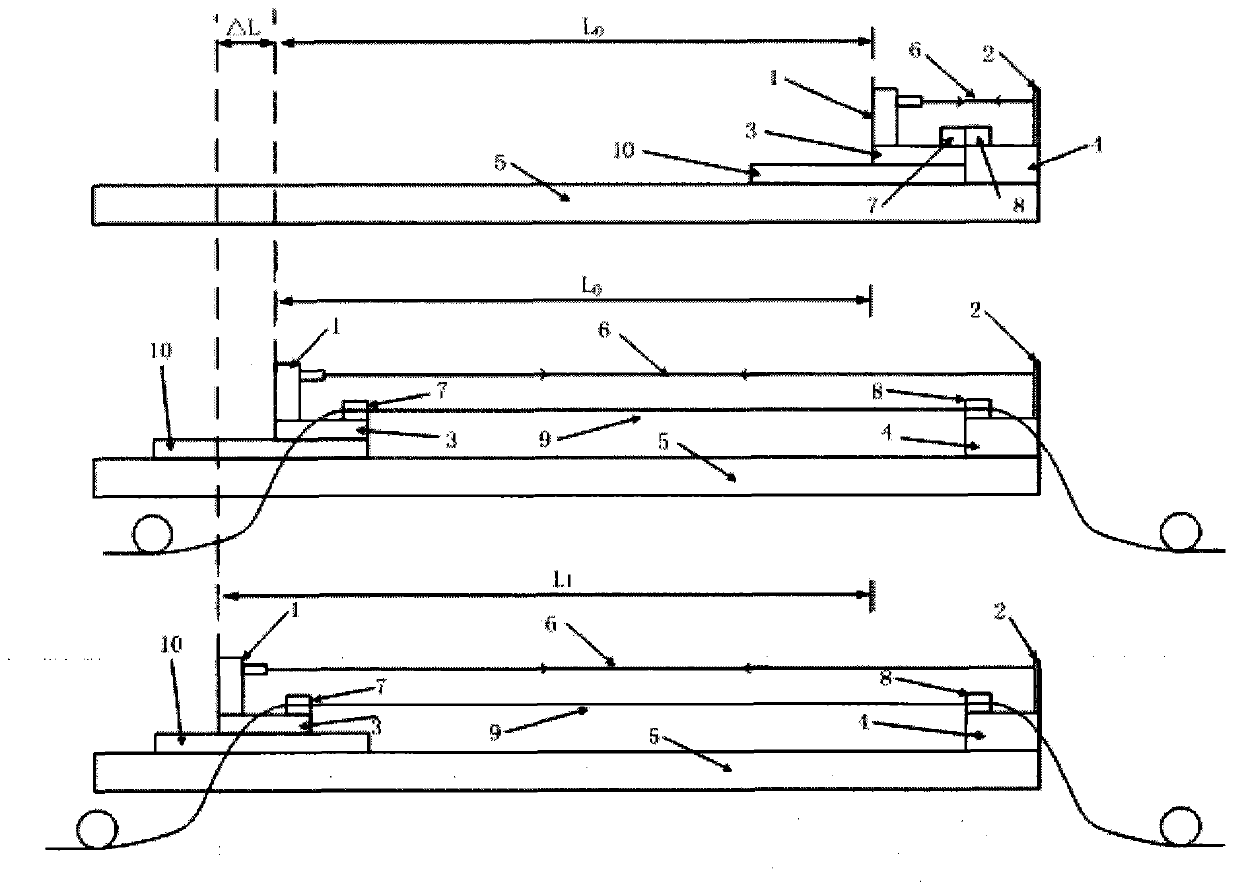

[0031] Such as figure 1 As shown, a long-distance and large-range optical fiber strain generation device of the present invention includes a dual-frequency laser interference length measurement device light source and a detector 1, a total reflection device 2, a left clamp carrying platform 3, and a right clamp carrying platform 4, which can move over a long distance Slide rail 5, distance measuring laser light path 6, left fixture 7, right fixture 8, tested optical fiber subject to strain 9, electric displacement stage base 10 fixed on the slide rail.

[0032] The invention uses a moving slide rail to convert distance measurement into displacement measurement, and accurately measures the original length and stretched length of the optical fiber through a high-precision dual-frequency laser length measurement device, thereby obtaining accurate strain measurement results. Dual-frequency laser measurement The displacement measurement accuracy of the long device is high and can b...

Embodiment 2

[0038] On the basis of the above examples, if figure 1 As shown, the present invention provides a long-distance and large-range optical fiber strain generation device, which includes a dual-frequency laser interference length measurement device, a light source and a detector 1 fixed on the left fixture carrying platform 3, and a total reflection device 2 fixed on the right fixture. On the platform 4, the light source and detector 1 of the dual-frequency laser interference length measurement device and the total reflection device 2 form a distance measuring laser optical path 6, which is used to measure the optical fiber displacement and optical fiber strain value. The present invention replaces the distance with displacement measurement measurement, greatly improving the accuracy of measurement.

[0039] Further, the left clamp 7 and the right clamp 8 are respectively set on the left clamp bearing platform 3 and the right clamp bearing platform 4, and the left clamp 7 and the ...

Embodiment 3

[0044] On the basis of the foregoing embodiments, further, as figure 1 As shown, the present invention also provides a long-distance and large-range optical fiber strain generation method, which includes the following steps:

[0045] Step A: forming a ranging laser light path;

[0046] Step B: record the displacement origin;

[0047] Step C: Move the base of the electronically controlled translation stage to the left, so that the strained part of the optical fiber under test is stretched straight, and then move the base of the electronically controlled translation stage to the right in small steps in the opposite direction. After each movement, the To start the BOTDR test the strain reading of the stretched section of the optical fiber, and record it as Y, when Y decreases to close to 0, record the reading of the dual-frequency laser interferometric length measurement device, and mark it as L0; the purpose of step C is to find out the The position of the stretched fiber segm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com