Method for measuring total porosity of shale

A technology of total porosity and measurement method, which is applied in the fields of mining exploration and development, petroleum, and geology. Porosity and other issues, to achieve the effect of easy operation, high measurement accuracy and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

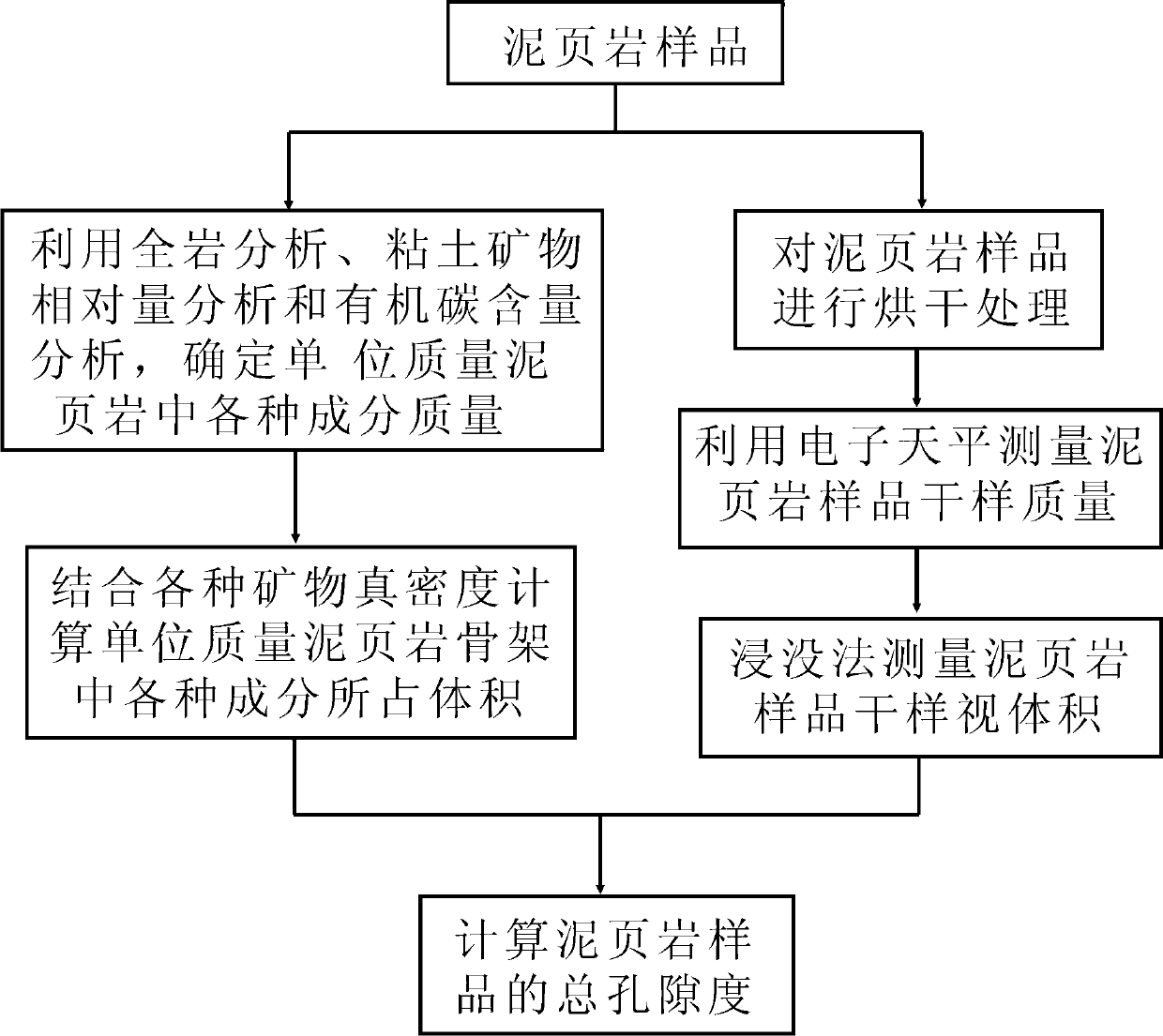

[0016] Embodiment 1: as figure 1 Described, a kind of shale total porosity measuring method comprises the following steps;

[0017] Step 1: Select a number of mud shale reservoir core samples in the target layer, conduct X-diffraction whole-rock analysis, clay mineral relative content and organic carbon content analysis on each mud shale sample, and determine the mud shale with a unit mass M of 100.00g The mass of quartz contained in the shale framework m 1 44.30g, potassium feldspar mass m 2 2.30g, mass of plagioclase m 3 12.30g, dolomite mass m 4 17.50g, pyrite quality m 5 4.50g, marcasite mass m 6 1.90g, montmorillonite mass m 7 0.26g, illite mass m 8 16.94g, organic carbon mass m 9 It is 9.51g.

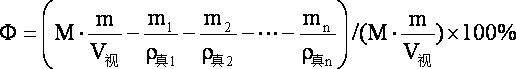

[0018] Step 2: On the basis of the weight of each mineral in the shale sample with a unit mass M of 100g obtained in step 1, according to the true density ρ of each mineral 真1 , ρ 真2 , ρ 真3 …ρ 真n , to calculate the volume V occupied by various components in the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com