Tin-carbon composite material for lithium secondary battery negative electrode and preparation method thereof

A lithium secondary battery and composite material technology, applied in battery electrodes, electrolyte battery manufacturing, non-aqueous electrolyte battery and other directions, can solve the problems of low melting point of tin, difficult particles, difficult mixing, etc., to improve rate performance, simple operation, The effect of reducing the volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

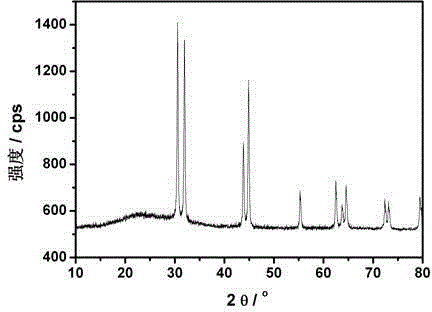

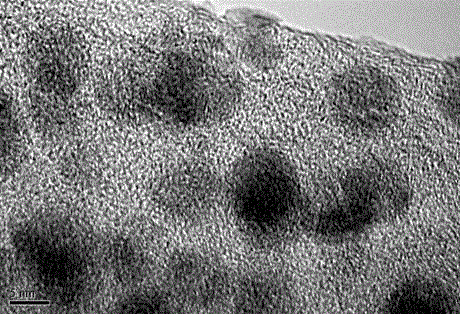

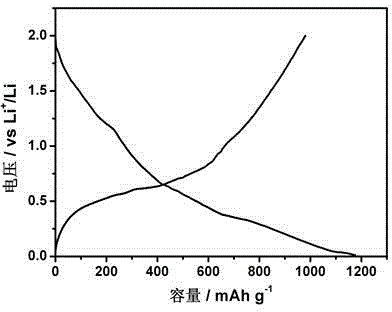

[0025]A tin-carbon composite material for the negative electrode of lithium secondary batteries, which is uniformly dispersed by ultra-small tin nanoparticles, embedded in a three-dimensional porous carbon carrier material and forms a three-dimensional porous structure, in which the tin nanoparticles have a high specific The high-capacity tin lithium storage material exists in the tin-carbon composite material as a tin-containing active material. The particle size range of tin nanoparticles is 5-6 nm, and the mass percentage of the tin-containing active material in the composite material is 56%.

[0026] The preparation method of the tin-carbon composite material used for lithium secondary battery negative pole, the steps are as follows:

[0027] 1) Synthesis of (salen)Sn

[0028] Add 100 ml of absolute ethanol to a solution containing 0.95 g of tin chloride (5 mmol) and 1.34 g of salenH 2 Ligand (5 mmol) in a 250 ml three-necked flask, then 1.4 mL triethylamine (10 mmol) was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com