Manufacturing method of pinhole collimator

A technology of collimator and pinhole, applied in accelerators, electrical components, etc., can solve the problems of large heavy ion beam spot, low-energy scattering of heavy ion micro-beam, unsatisfactory pinhole shape, etc., to achieve good straightness and quality Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

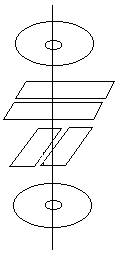

[0025] A preparation method of a pinhole collimator, the steps are as follows:

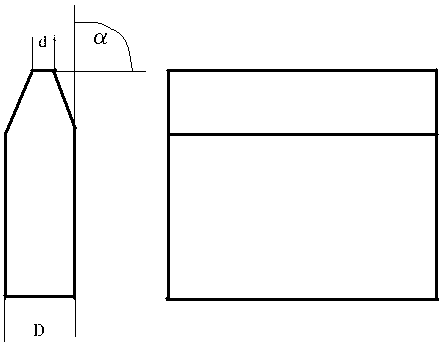

[0026] 1) Grinding of the blade

[0027] First, prepare the mold, which requires that the mold has two faces that are plane and perpendicularly intersect, and the intersection forms a straight edge; the blade is fixed on a plane of the mold, and the top of the blade edge is parallel to the straight edge and slightly protrudes above the the straight edge;

[0028] Fix the precision sandpaper on the flat plate, and then place the fixed blade and mold on the precision sandpaper, so that the blade is perpendicular to the precision sandpaper and the top of the blade edge is in contact with the precision sandpaper, and the relative movement of the mold and the precision sandpaper is controlled to make the blade edge The top is ground to be smooth and clean, and the thickness of the cutting edge is required to ensure that the collimated object will not be transmitted;

[0029] 2) Splicing of slit struc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com