Rotary electric machine driving system

一种旋转电机、驱动系统的技术,应用在控制系统、控制发电机、电动机控制等方向,能够解决再生转矩减小等问题,达到防止过多电流流过、抑制过多电流流过定子线圈、增加转矩的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

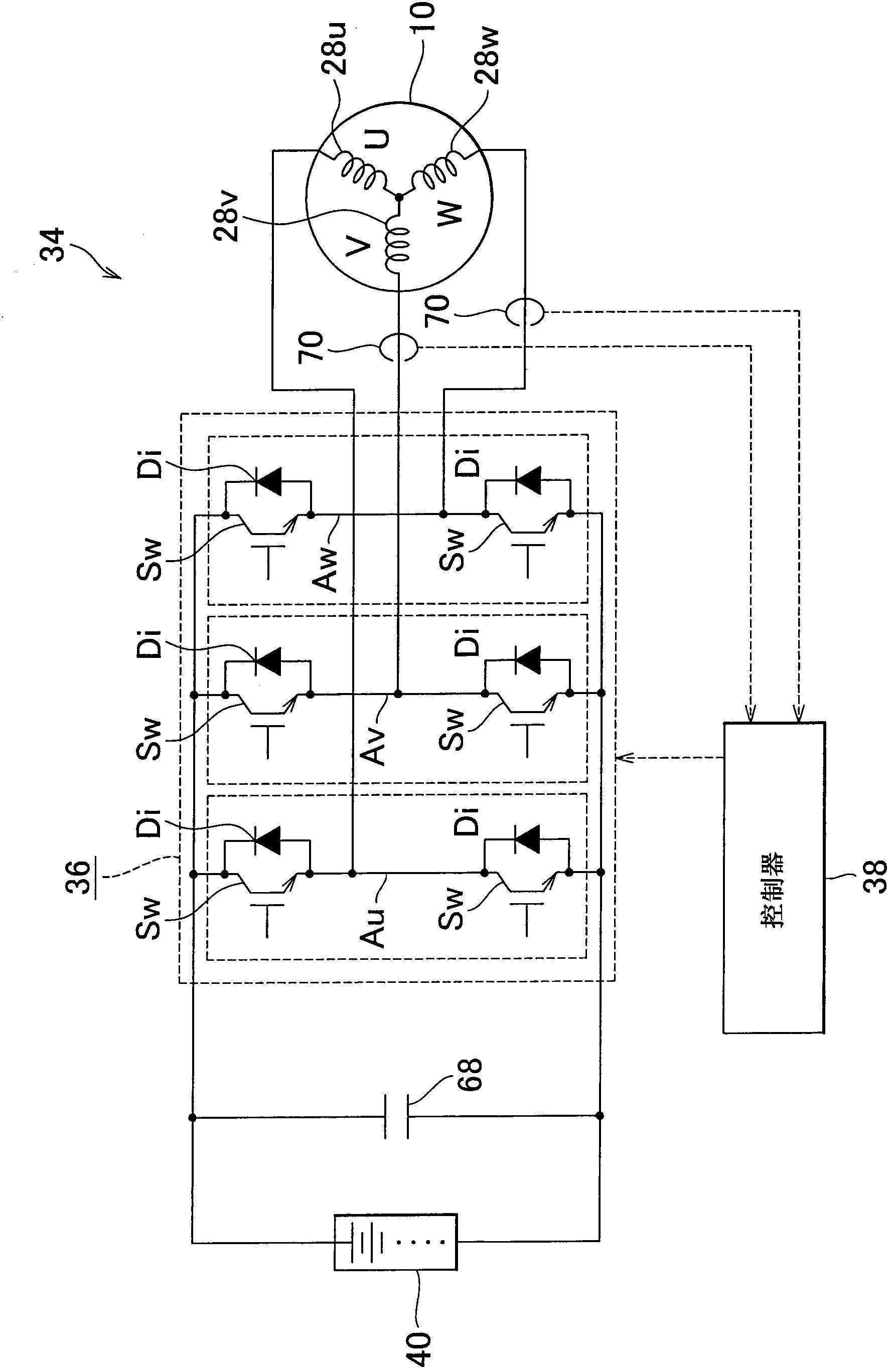

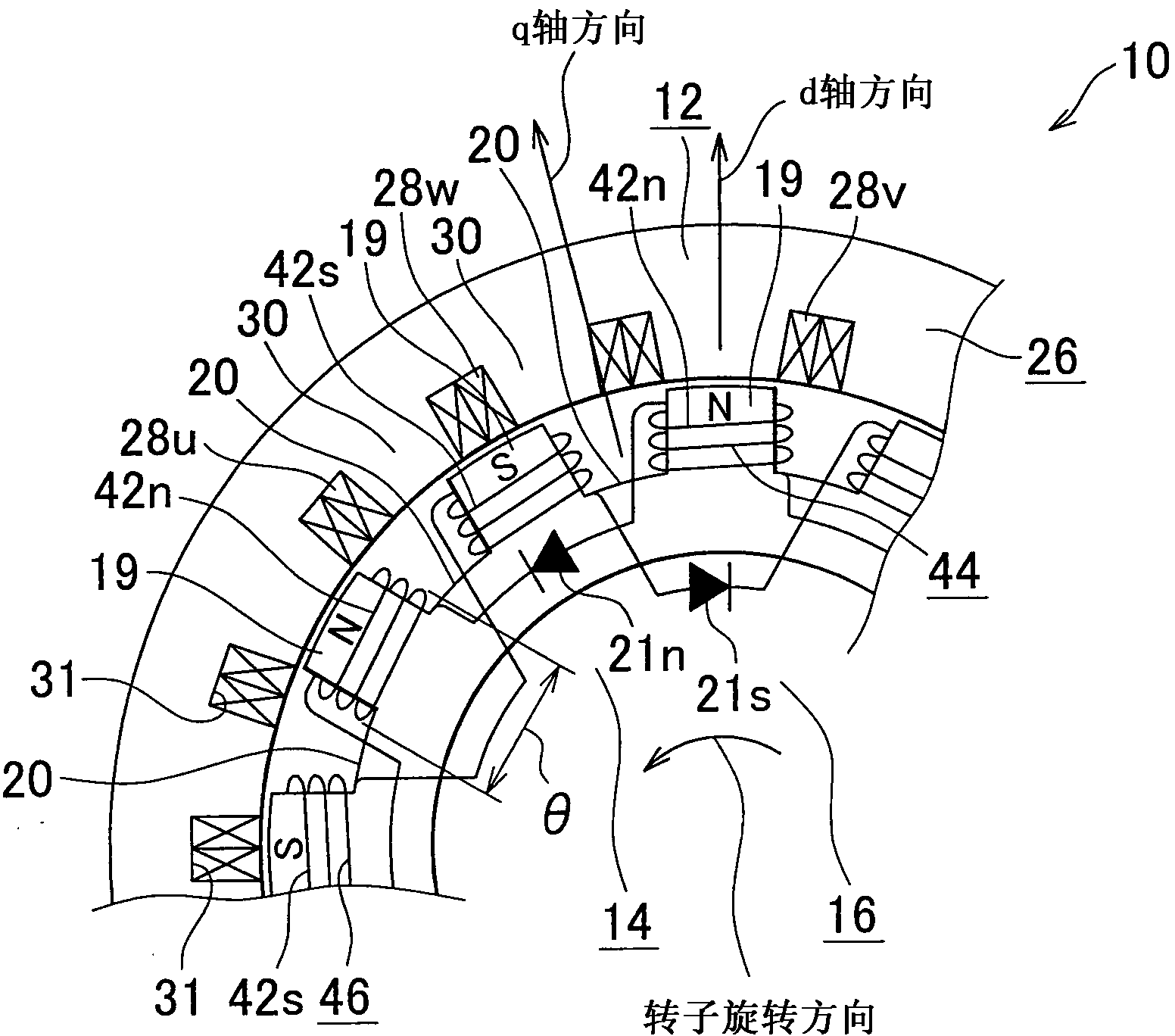

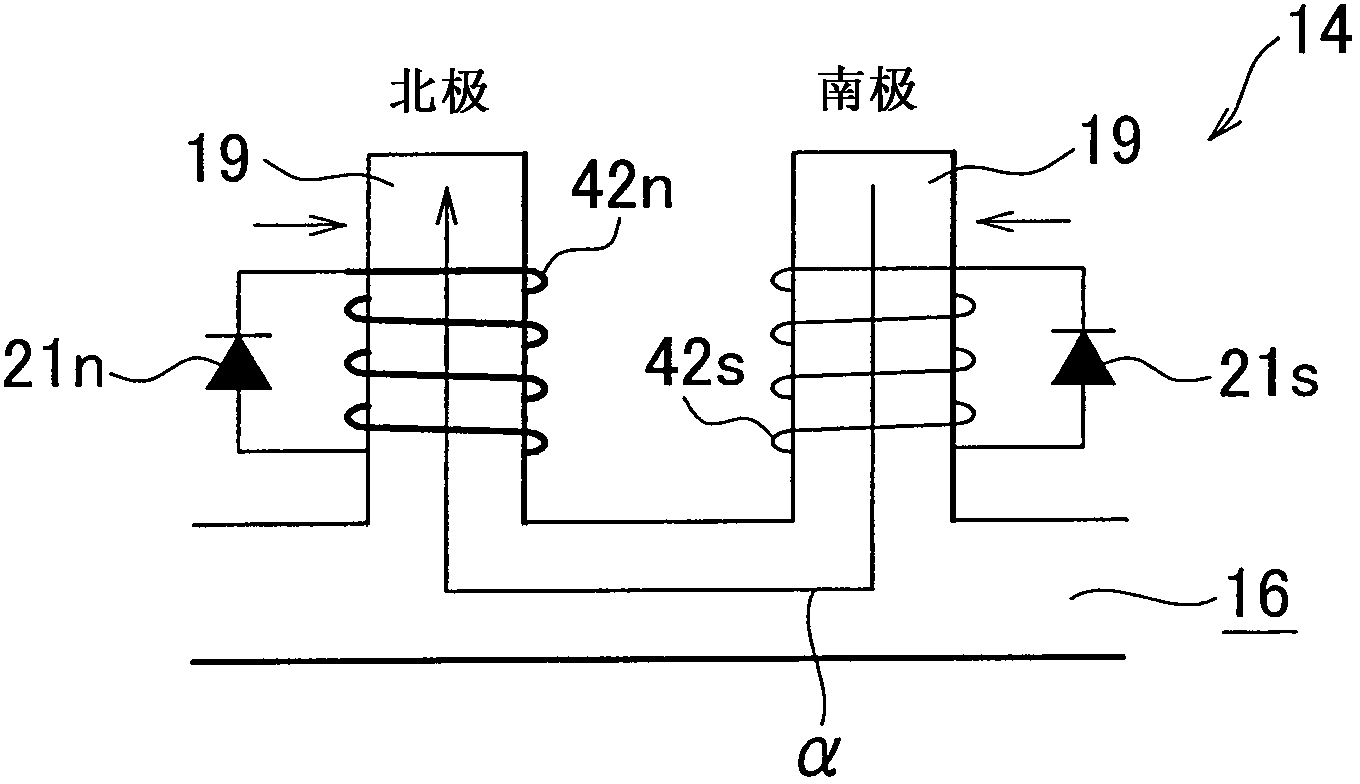

[0049] Figure 1 to Figure 8 and Figure 10 is a view showing an embodiment of the present invention. figure 1 is a view showing a schematic configuration of the rotating electric machine drive system according to the present embodiment. figure 2 is a schematic diagram partially showing a portion of the stator facing the rotor in this embodiment. Figure 3A is a schematic diagram showing a state in which magnetic flux passes through the rotor in this embodiment. Figure 3B is shown by calculating the magnitude of the flux linkage with the rotor coil while changing figure 2 A graph of the results obtained for the rotor coil width θ in the circumferential direction in the rotating electrical machine shown in . Figure 4 is a block diagram showing the configuration of the controller in the embodiment of the present invention. Such as figure 1 As shown, the rotating electric machine drive system 34 according to the present embodiment includes the electric rotating machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com