A far-infrared temperature-controlled meat jerky oven with automatic cleaning function

An automatic cleaning and far-infrared technology, applied in high-frequency/infrared heating and baking, food ovens, baking, etc., can solve the problems of ignoring the drying characteristics of meat products, incomplete drying, and over-drying, and shorten the baking time , extended shelf life, easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

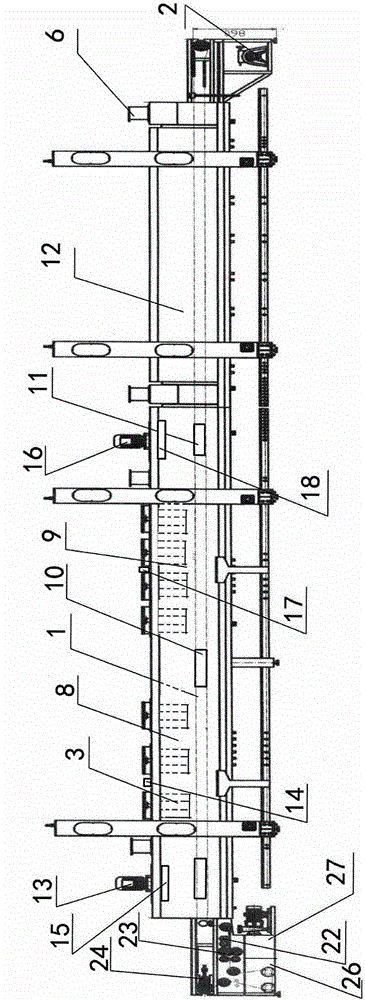

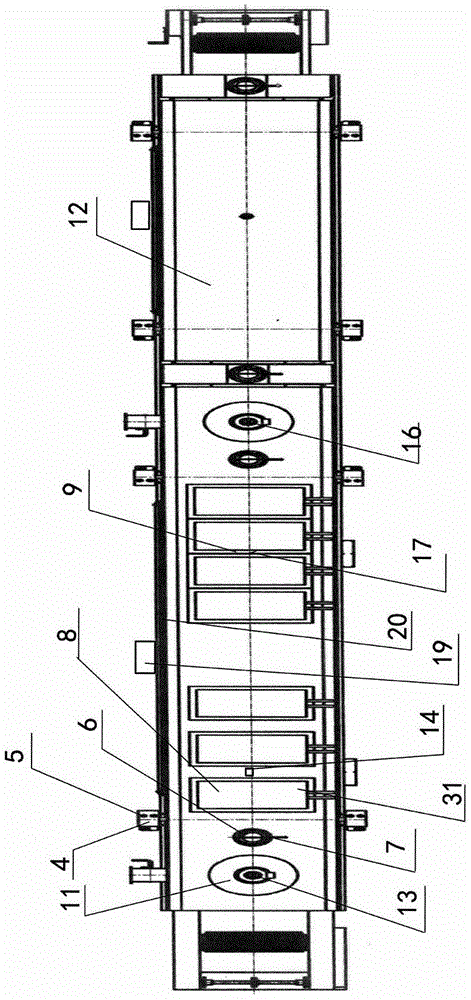

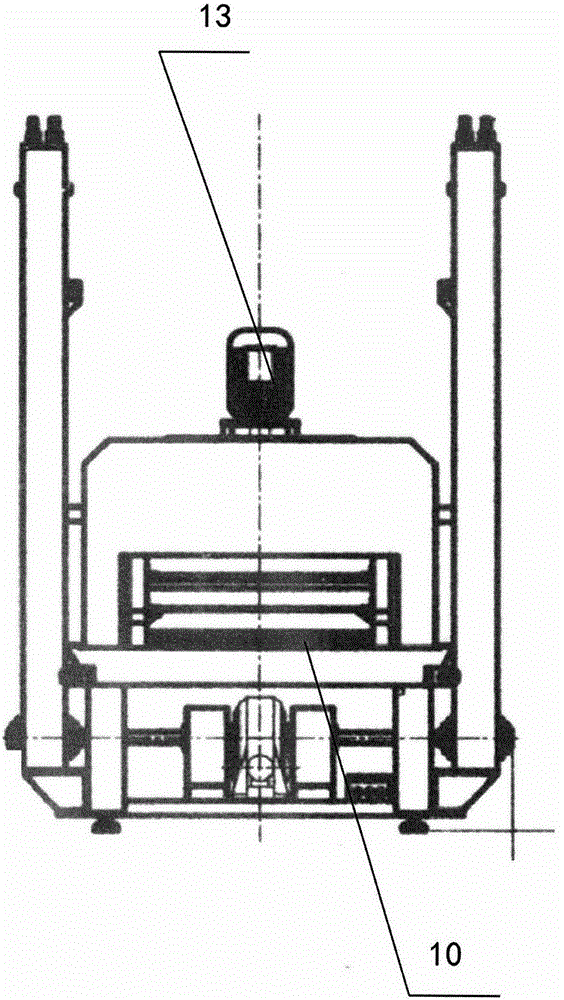

[0014] exist figure 1 , figure 2 and image 3 Among them, the present invention provides a far-infrared temperature-controlled jerky oven with automatic cleaning function, which includes a long and hollow stainless steel furnace body, a conveyor belt 1, a drive motor 2 and an exhaust pipe 6, and the conveyor belt 1 consists of a head Pass through the stainless steel furnace body at the end, the tail of the stainless steel furnace body is provided with a drive motor 2, the drive motor 2 is connected to the conveyor belt 1, and the drive motor 2 drives the conveyor belt 1 to circulate in the stainless steel furnace body. It is characterized in that the The side of the stainless steel body of furnace is provided with an air inlet 4, and the air inlet 4 communicates with the stainless steel furnace body, and an air inlet valve 5 is arranged on the air inlet 4, and several exhaust pipes 6 are distributed on the top of the stainless steel body of furnace. The exhaust pipe 6 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com