Construction method of integrally-poured architecture building

A construction method and housing technology, applied in the direction of construction, building components, building structure, etc., can solve the problems of long construction period, increase construction cost, affect construction efficiency, etc., and achieve the goal of reducing construction cost, facilitating quality control, and improving construction efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order for those skilled in the art to better understand the technical solutions provided by the present invention, the following will be described in conjunction with specific embodiments.

[0039] The implementation steps of the building construction method of integrated pouring provided by the invention are as follows:

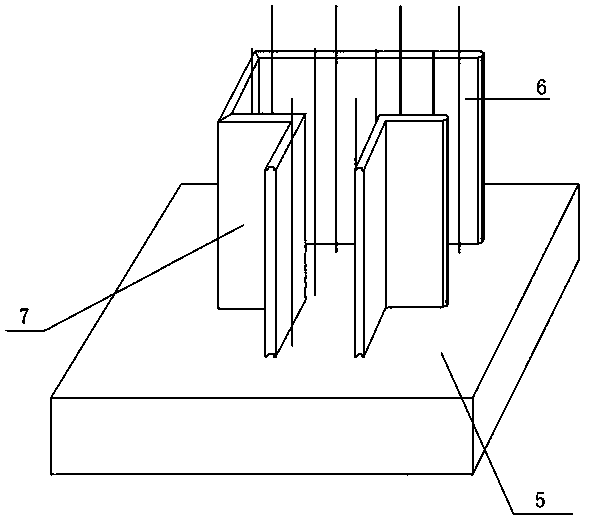

[0040] The first step, foundation construction: reinforced concrete foundation, in which the longitudinal steel bars protrude upward from the reinforced concrete foundation, and are used to overlap with the steel bars in the walls and columns.

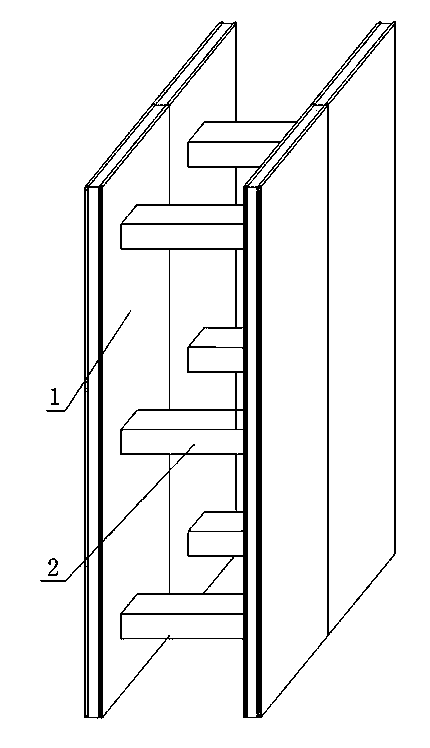

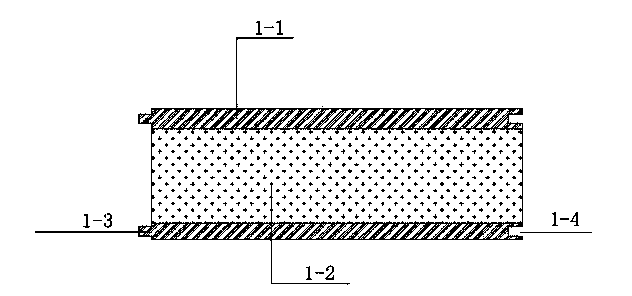

[0041] The second step, exterior wall and column construction: first erect the outer wall panel and outer column panel of the outer wall and clamp the outer wall panel and outer column panel, and use the outer frame to temporarily support the outer wall panel and outer column panel , fix, and then tie the wall reinforcement and column reinforcement, and then install the support block with the floating end i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com