Automatic hydraulic pipe arrangement device

An automatic discharge and hydraulic technology, which is applied in the fields of fluid pressure actuation device, fluid pressure actuation system safety, drilling pipe, etc. problem, to achieve the effect of compact structure, simple structure and constant displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

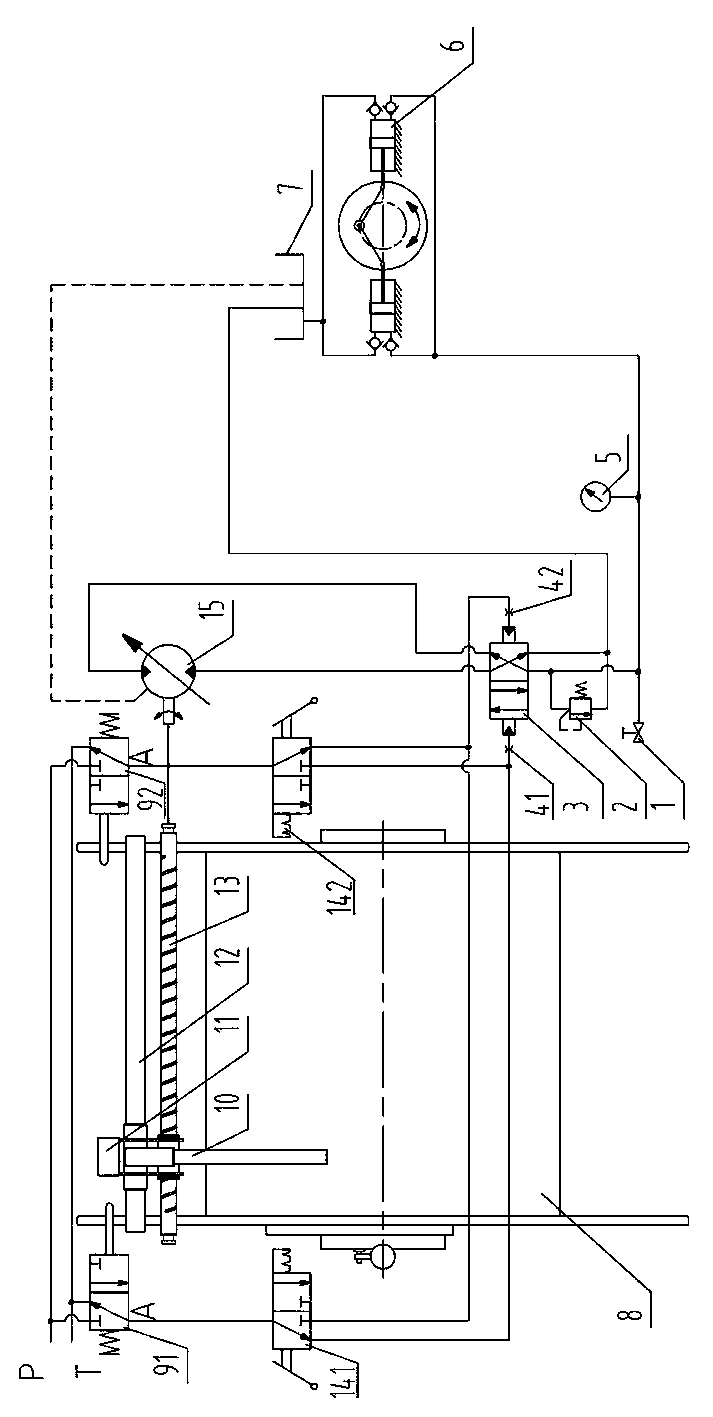

[0023] like figure 1 or figure 2 As shown in one of them, a hydraulic automatic pipe rowing device includes a pipe rower 10, a guide rod 12, a screw 13 and a rotating reel 8. The pipe rower 10 is provided with a touch block 11, and the pipe rower 10 is set On the screw rod 13 , the pipe rower 10 is driven by a hydraulic system, and can move back and forth along the screw rod 13 axially under the guidance of the guide rod 12 .

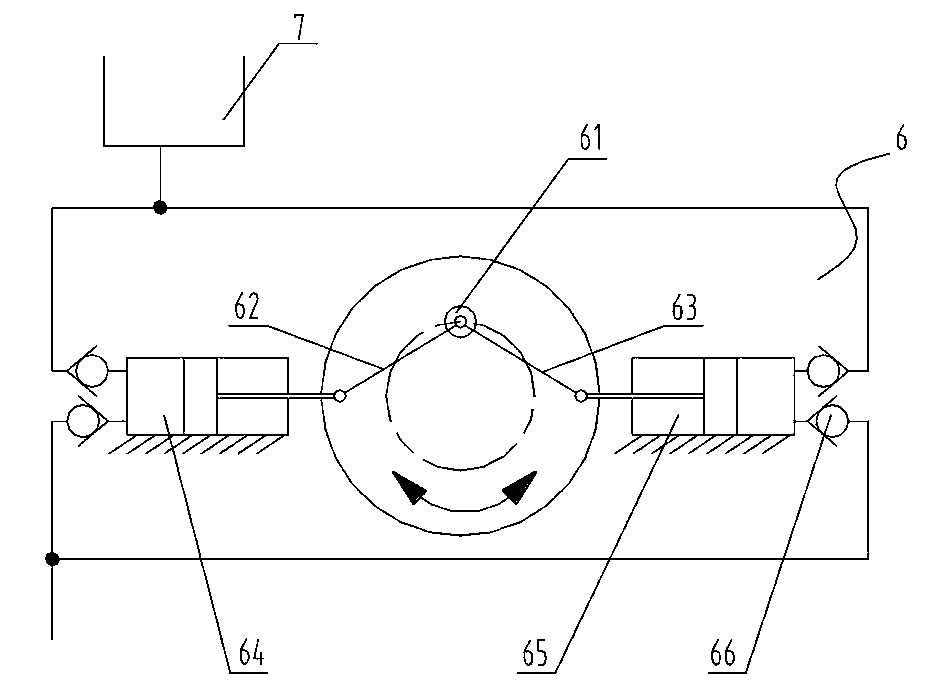

[0024] The hydraulic system includes a driving oil circuit and a control oil circuit. The driving oil circuit includes a fuel tank 7, a hydraulic pump 6, a hydraulic valve 3, a hydraulic motor 15 and an on-off valve 1. The hydraulic pump 6 is driven by a rotating drum 8, And the oil inlet of hydraulic pump 6 is connected with oil tank 7, and the oil outlet of hydraulic pump 6 is connected with hydraulic valve 3, and described hydraulic valve 3 is also connected with hydraulic motor 15 and fuel tank 7 respectively, and the power of hydraulic motor 15 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap