Combined polymer material gear structure

A technology of polymer material and gear structure, applied in belts/chains/gears, components with teeth, portable lifting devices, etc. Rigidity, simple manufacturing process, and the effect of improving load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

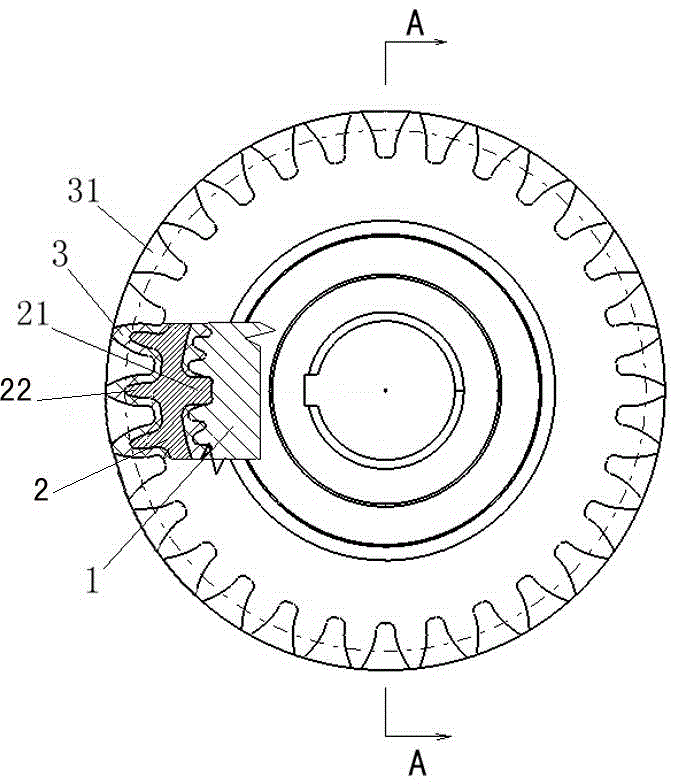

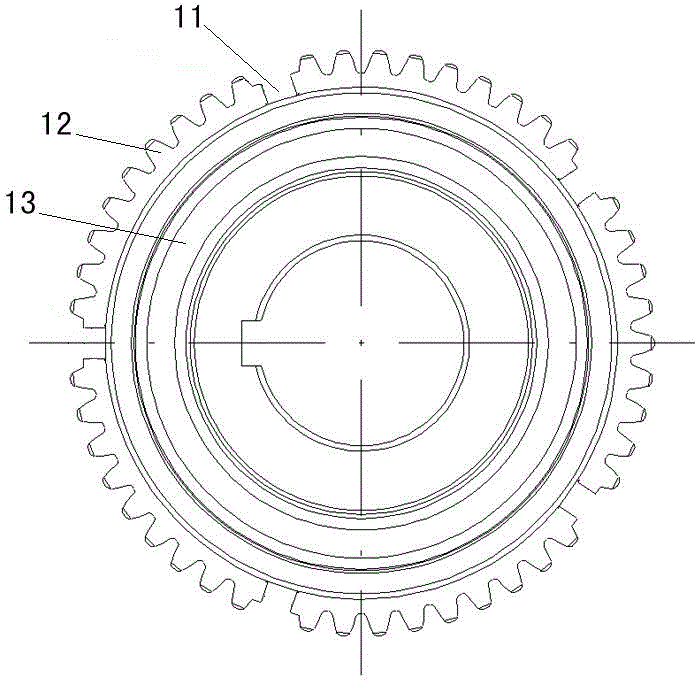

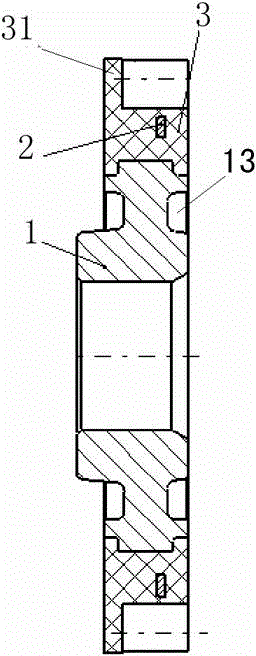

[0019] attached figure 1 It is a schematic front view of the combined polymer material gear structure of the present invention, with figure 2 It is a schematic front view of the gear structure metal insert of the present invention, with image 3 It is a right-view sectional schematic diagram of the combined polymer material gear structure of the present invention. In the figure, 1 is a metal insert, 2 is a ring gear insert, 3 is a polymer tooth type, 11 is a slot, 12 is a connecting tooth, 13 is a weight-reducing groove, 21 is a stop tooth, 22 is a ring gear, 31 To strengthen the tendons. It can be seen from the figure that the combined polymer material gear structure of the present invention includes a metal insert 1, a ring gear insert 2 and a polymer material tooth profile 3; The number, distribution position and size of the slots 11 match the stop teeth 21 on the inner circle of the ring gear insert 2, and weight-reducing grooves 13 are provided on the end faces of bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com