Efficient, clean combustion and low-exhaust gasifying heating stove

A heating stove, high-efficiency technology, applied in household stoves/stoves, home appliance efficiency improvement, climate sustainability, etc., can solve problems such as smoke pollution emissions, achieve high temperature, strong firepower, and improve thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

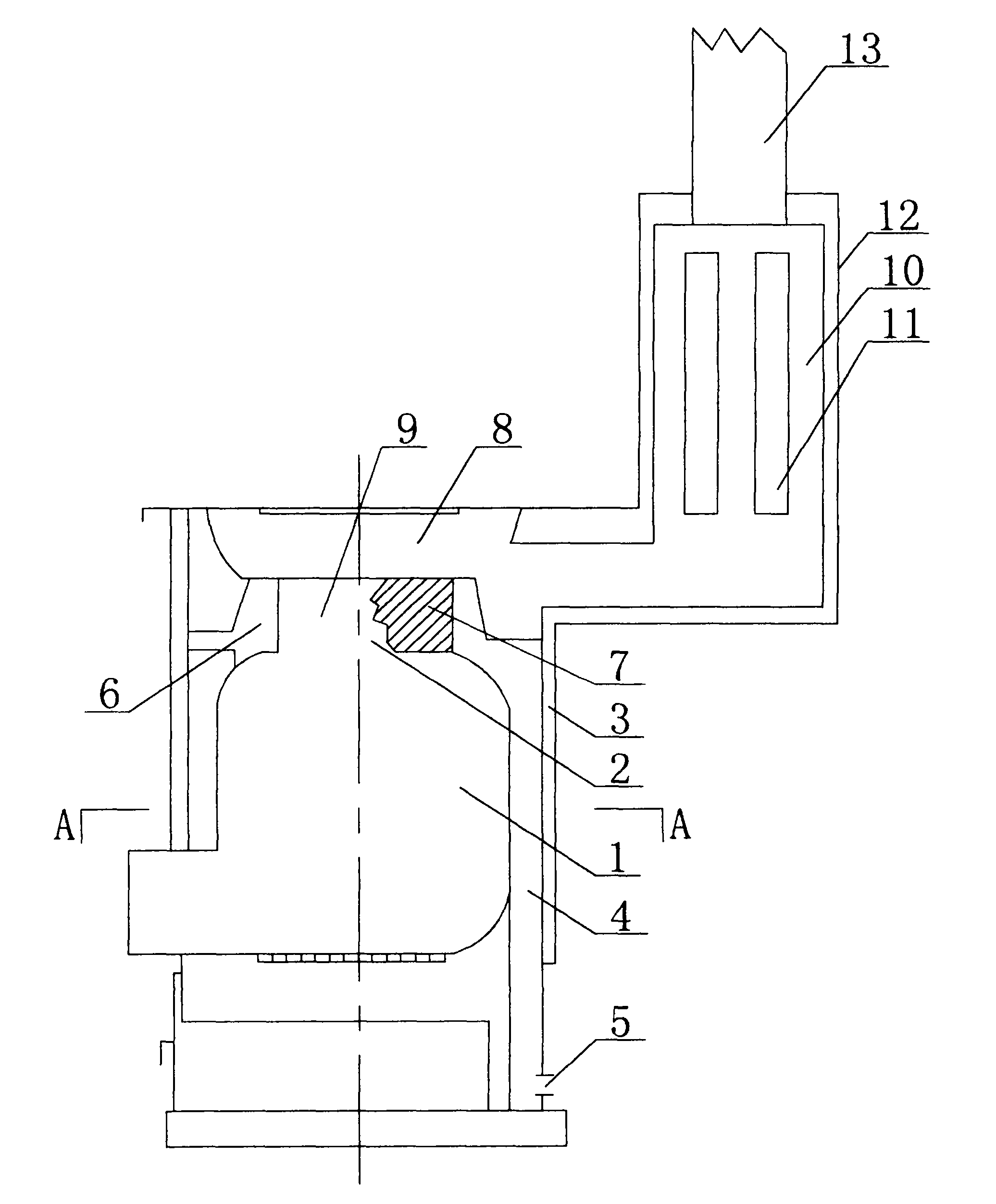

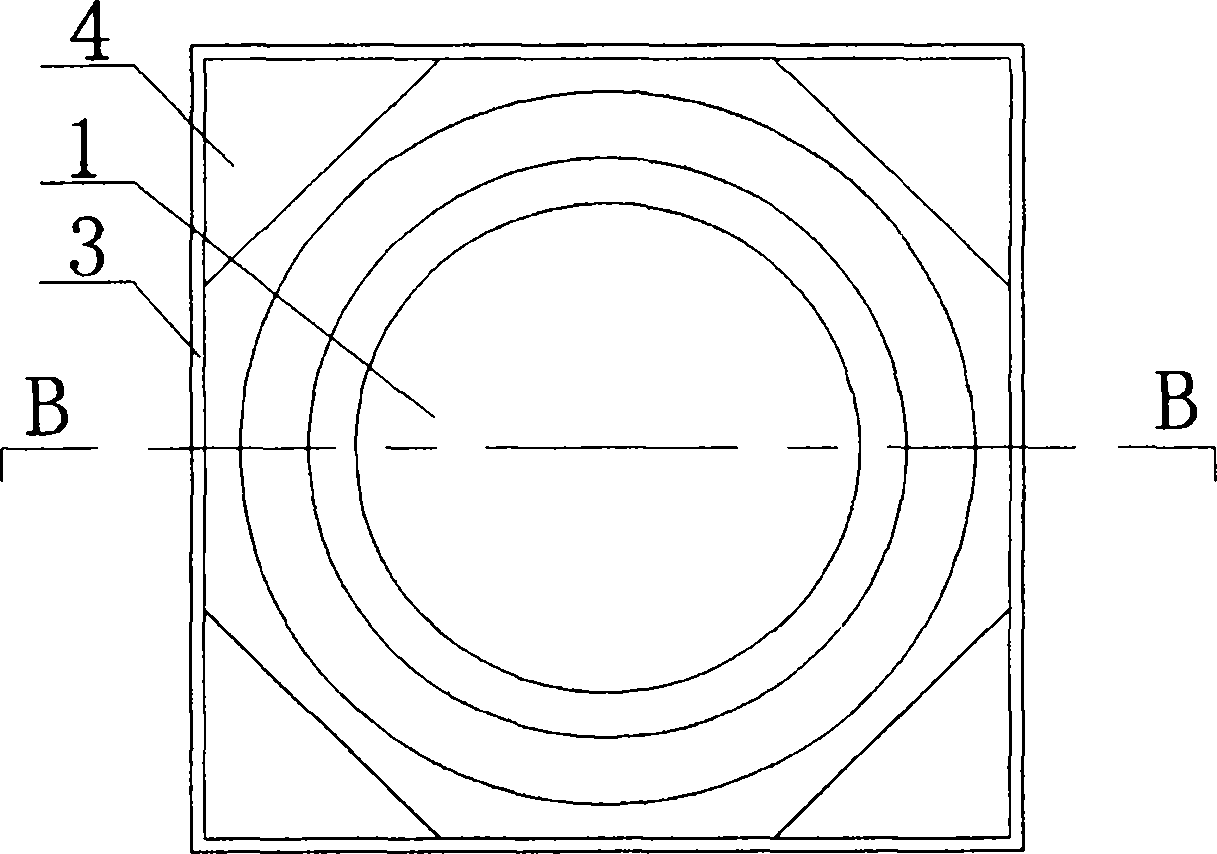

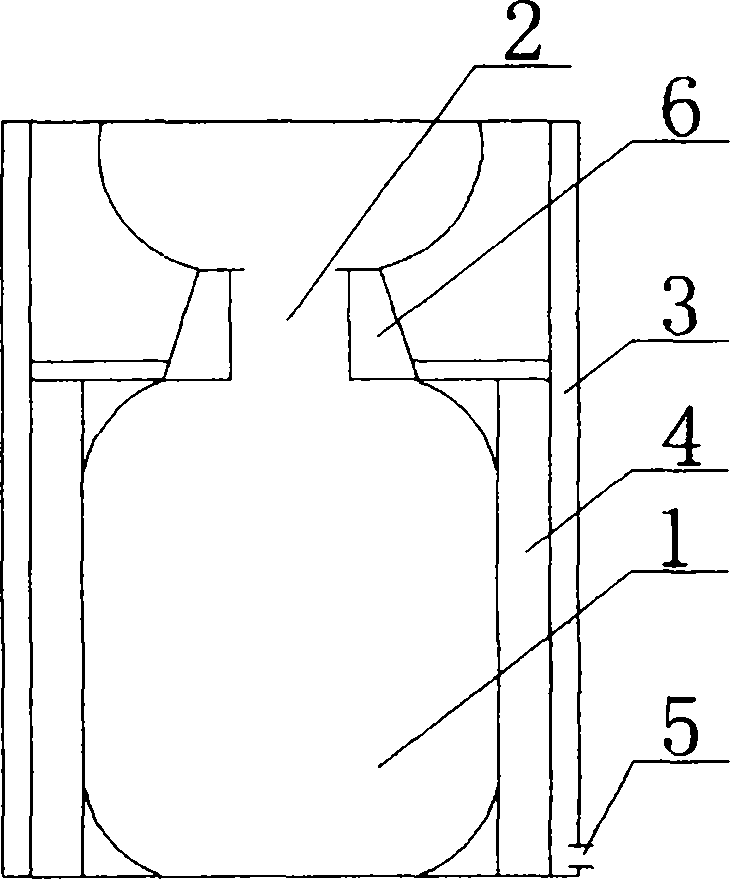

[0015] The present invention will be described in detail below with reference to the accompanying drawings. As shown in the drawings, the structure of the present invention includes a first combustion chamber 1, a second combustion chamber 2, a water channel interlayer 3, an air inlet channel 4, an air inlet 5, an air storage bin 6, an inner wall of the air storage bin 7, and an upper fire outlet 8. Fire inlet hole 9 at the lower end, heat dissipation flue 10, water channel plate interlayer 11 in the heat-absorbing box, heat-absorbing box 12, and chimney 13. It is characterized in that the second combustion chamber 2 is arranged on the upper part of the first combustion chamber 1, and the second A gas storage bin 6 is arranged outside the combustion chamber 2, a lower end fire inlet hole 9 is arranged between the first combustion chamber 1 and the second combustion chamber 2, and an upper end fire outlet hole 8 is arranged above the second combustion chamber 2, and the first co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com