Negative temperature coefficient ntc thermistor for motor protection and manufacturing method thereof

A technology of negative temperature coefficient and thermistor, which is applied in the direction of resistors with negative temperature coefficient, etc., can solve the problem that it cannot be used as an induction device for motor over-temperature protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The consumption of each component by weight percentage is respectively:

[0026] MnO 2 : 43.5%

[0027] co 2 o 3 : 17.2%

[0028] NiO: 24.8%

[0029] CuO: 13.5%

[0030] Fe 2 o 3 : 1.0%.

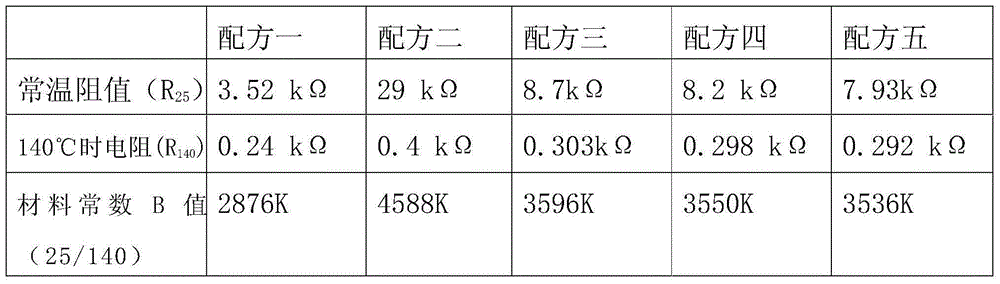

[0031] The properties of the product obtained by the above manufacturing method are: the resistance at 140°C is 0.24kΩ, the room temperature resistance is 3.52kΩ, and the material constant B(25 / 140) value is 2876K, which shows that these technical indicators are on the low side.

Embodiment 2

[0033] Each component is calculated by weight percentage, and consumption is respectively:

[0034] MnO 2 54.7%;

[0035] co 2 o 3 27.3%;

[0036] NiO is 12.4%;

[0037] CuO is 4.6%;

[0038] Fe 2 o 3 1.0%.

[0039] The properties of the product obtained by the above manufacturing method are: resistance at 140°C is 0.4KΩ, room temperature resistance is 29KΩ, material constant B(25 / 140) value is 4588K, it can be seen that these technical indicators are too large.

Embodiment 3

[0041] The consumption of each component by weight percentage is respectively:

[0042] MnO 2 : 51.0%;

[0043] co 2 o 3 : 22.5%;

[0044] NiO: 20.3%;

[0045] CuO: 5.1%;

[0046] Fe 2 o 3 : 1.1%.

[0047] The product obtained by the above-mentioned manufacturing method has the following properties: the resistance at 140°C is 0.303KΩ, the room temperature resistance is 8.7KΩ, and the material constant B (25 / 140) value is 3596K, which fully meets the technical indicators stated in the purpose of the invention.

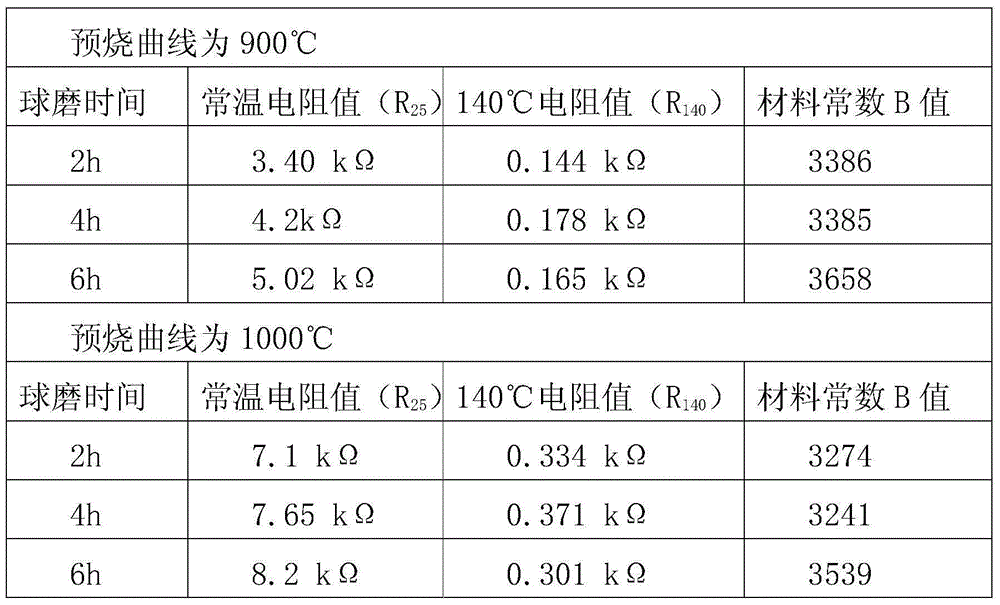

[0048] In Example 3, after repeated tests, it was found that when the sintering curve at 1350°C and the ball milling speed at 300r / min were constant, different ball milling times and pre-burning curves resulted in different chip results. See the table below for details:

[0049]

[0050] As can be seen from the above table, when the ball milling time is 6 hours each time and the pre-burning temperature is 1000°C, the technical parameters of the NTC thermisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com