Thyristor converter valve components

A thyristor converter valve and component technology, which is applied to electrical components, electro-solid devices, semiconductor devices, etc., can solve the problems of high water leakage probability, many waterway joints, and many branch water pipes, etc., and achieves the effect of prolonging the service life and simplifying the design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

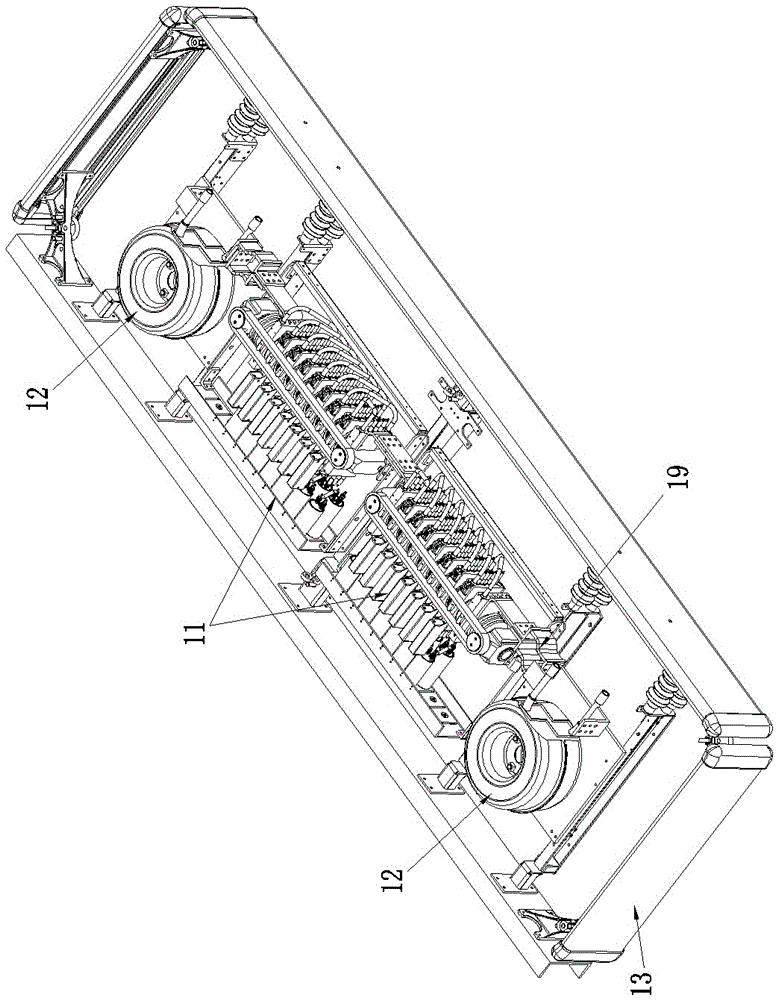

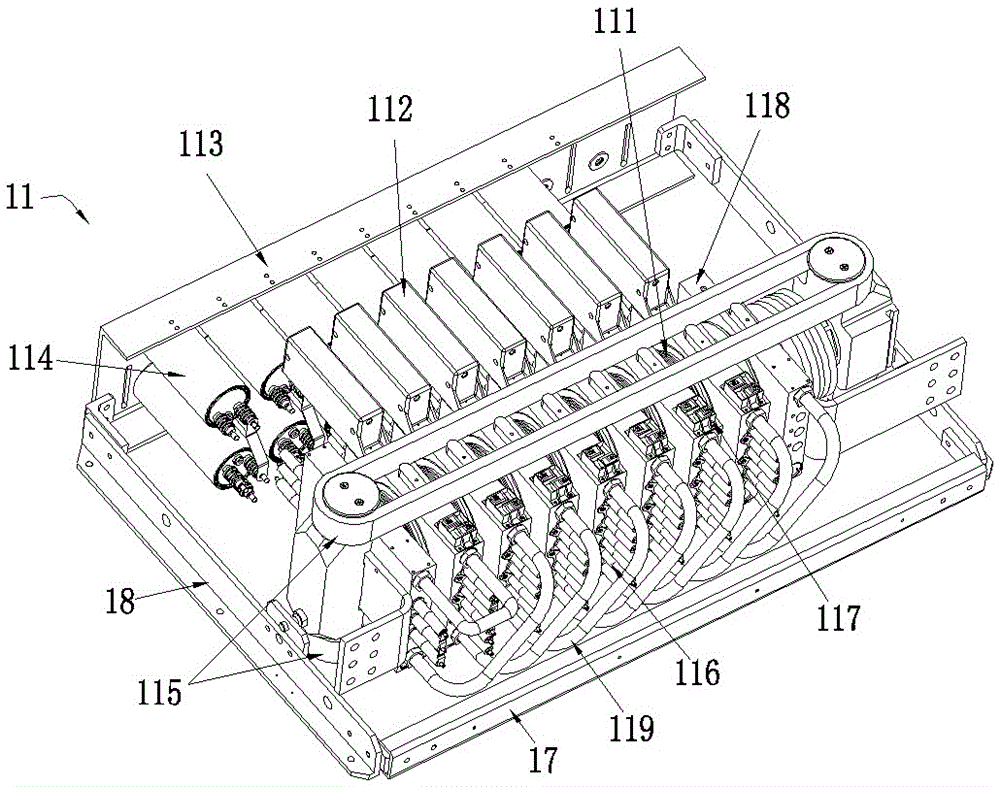

[0016] Examples of thyristor valve assemblies, such as Figure 1-3 As shown, the thyristor converter valve assembly includes a valve module 11 and a corresponding reactor 12. There are two valve modules 11 and two reactors 12 each, and they are both detachable and fixedly assembled on a frame-like base 13. Two reactors 12 are located at the left and right ends of the base 13 , and the valve module 11 is located between the two reactors 12 .

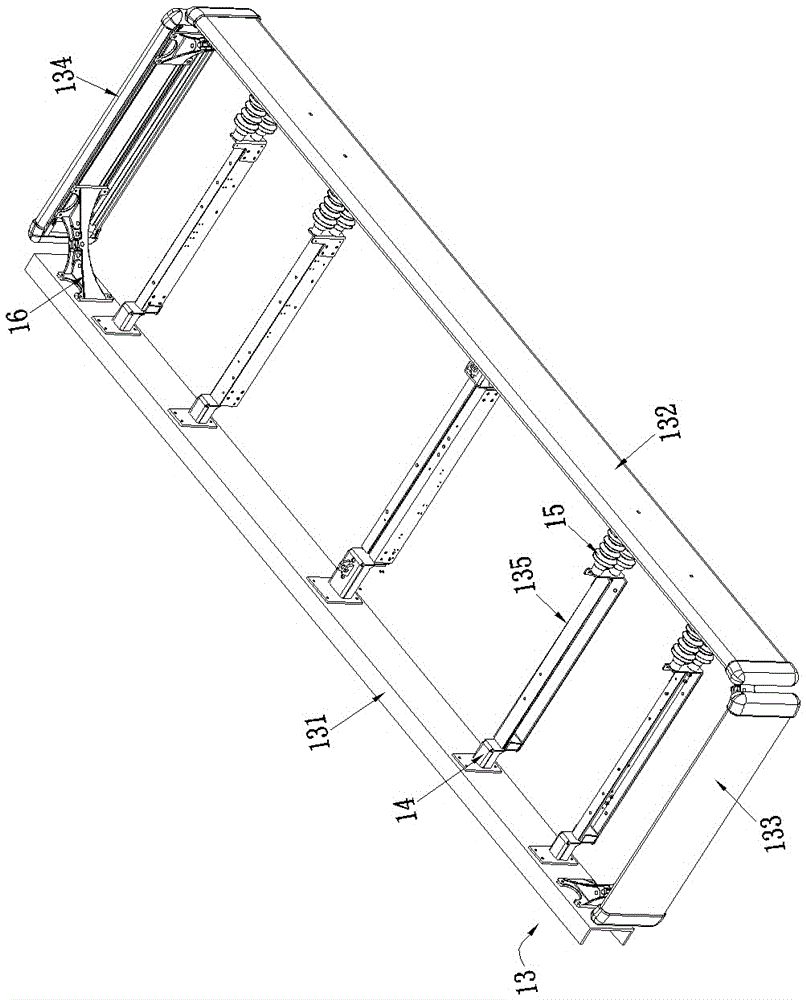

[0017] The base 13 is rectangular and includes a front frame 131, a rear frame 132, a left frame 133, a right frame 134 and a support beam 135 bridged between the front and rear frames. In this embodiment, the left frame 133, the right frame 134, the rear frame The frame 132 is made of aluminum profile, the front frame 131 and the support beam 135 are made of insulating material, the support beam 135 is bridged between the front and rear frames, and its front end is connected with the fixed connection block 14 provided on the front frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com