Fiber heating flexible cable

A flexible cable and fiber technology, applied in the direction of heating element material, heating element shape, etc., can solve the problems of excessive local current, difficulty in making electric heating body, low thermal efficiency, etc., and achieve the effect of improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical scheme of the present invention will be further described below through specific embodiments:

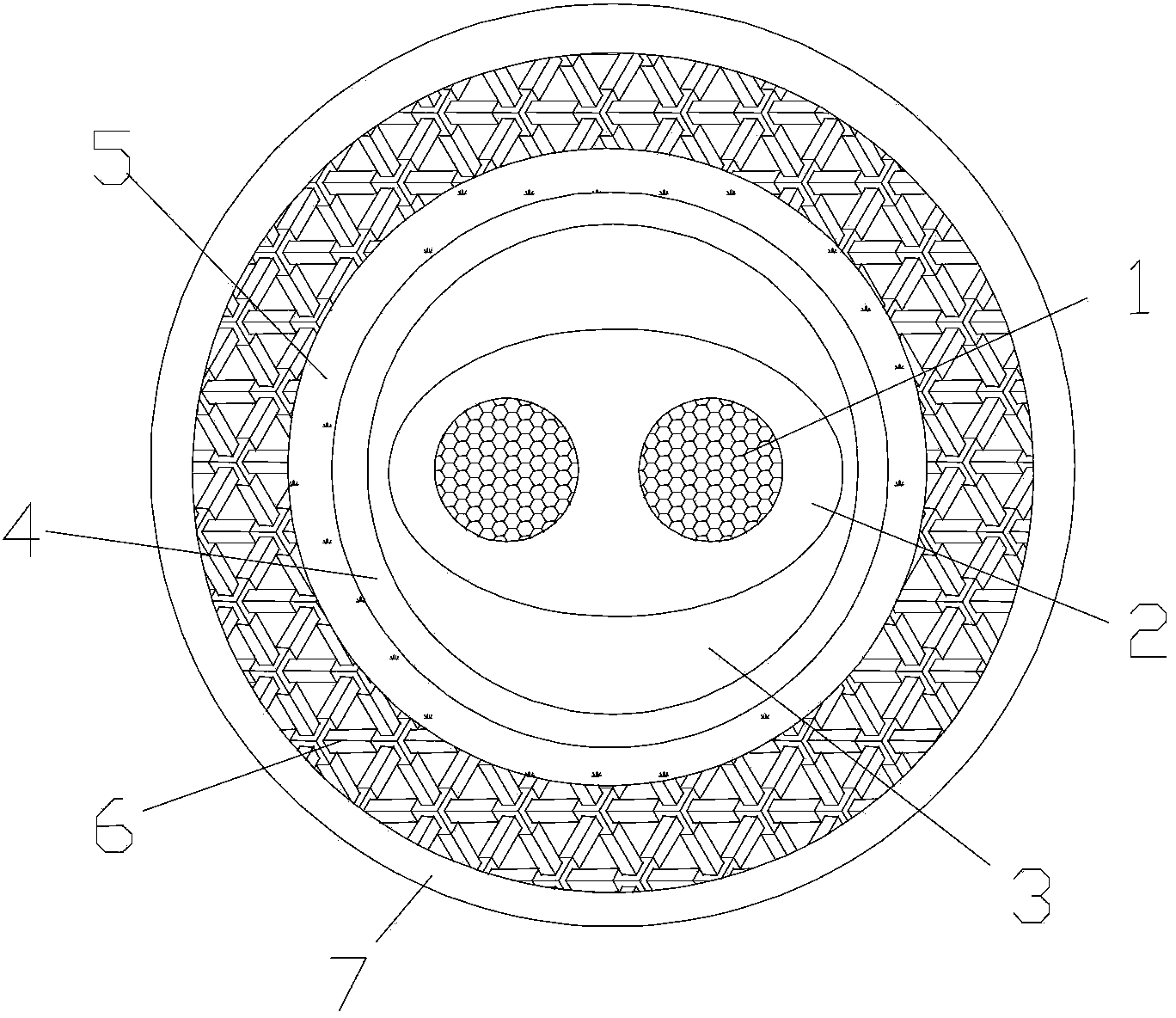

[0012] The invention provides a fiber heating flexible cable, which includes a conductor 1, the conductor 1 is formed by twisting several copper wires, and the diameter of the conductor 1 is 0.1 mm; acrylonitrile-styrene-butane is extruded outside the conductor An ethylene-propylene copolymer insulating layer 2 and an ethylene-propylene rubber film layer 3, the ethylene-propylene rubber film layer 3 is tightly wrapped around the outer periphery of the acrylonitrile-styrene-butadiene copolymer insulating layer 2, and the ethylene-propylene rubber film layer Layer 3 is tightly covered with a layer of semi-conductive nylon tape 4, and the outer layer of the semi-conductive nylon tape 4 is provided with a nickel-sprayed high-strength fiber heating wire 5, and the high-strength fiber heating wire is covered with an insulating layer 6. Finally, a layer of polyperfluor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com