Catalytic reactor with cooling device provided with tangential injection of cooling fluid

A technology for catalytic reactors and cooling fluids, applied in chemical/physical/physicochemical nozzle reactors, chemical instruments and methods, catalyst activation/preparation, etc., can solve problems such as difficulty in installing and maintaining reactors, bulky injection tubes, etc. , to achieve the effect of increased volume, easy mechanical assembly, and moderate cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

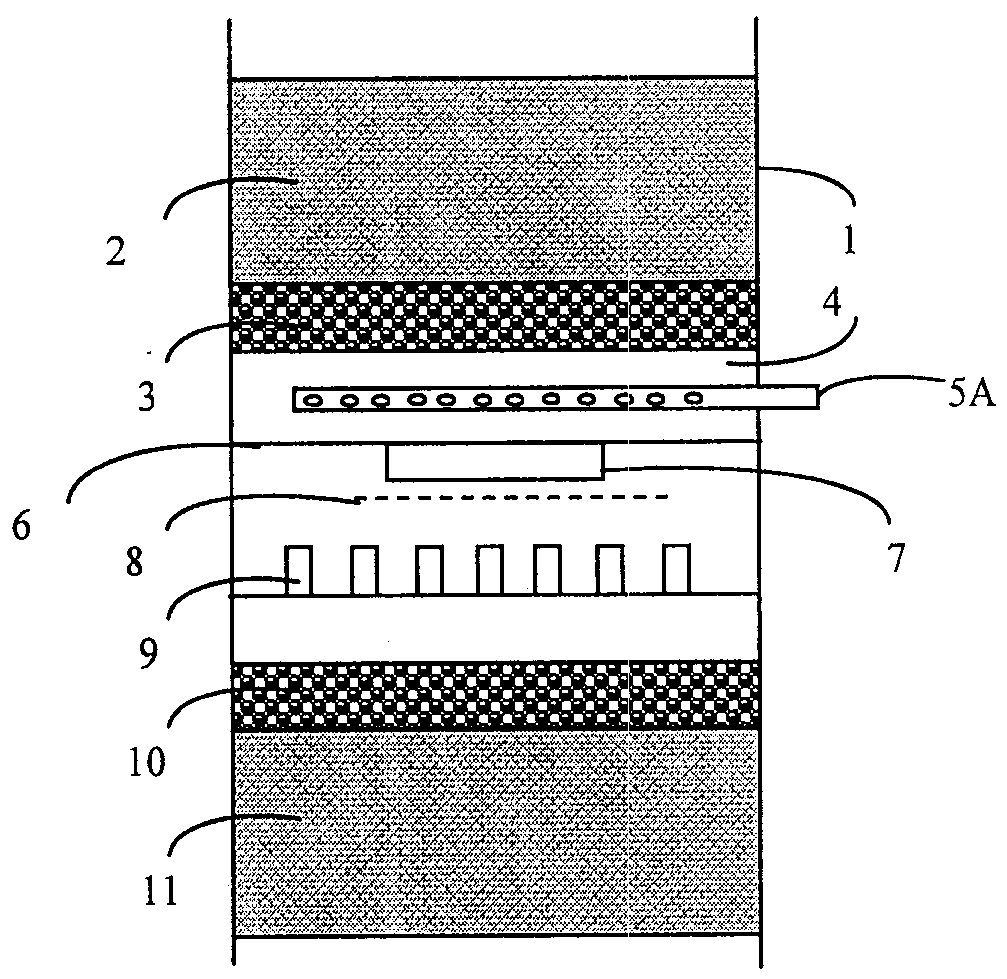

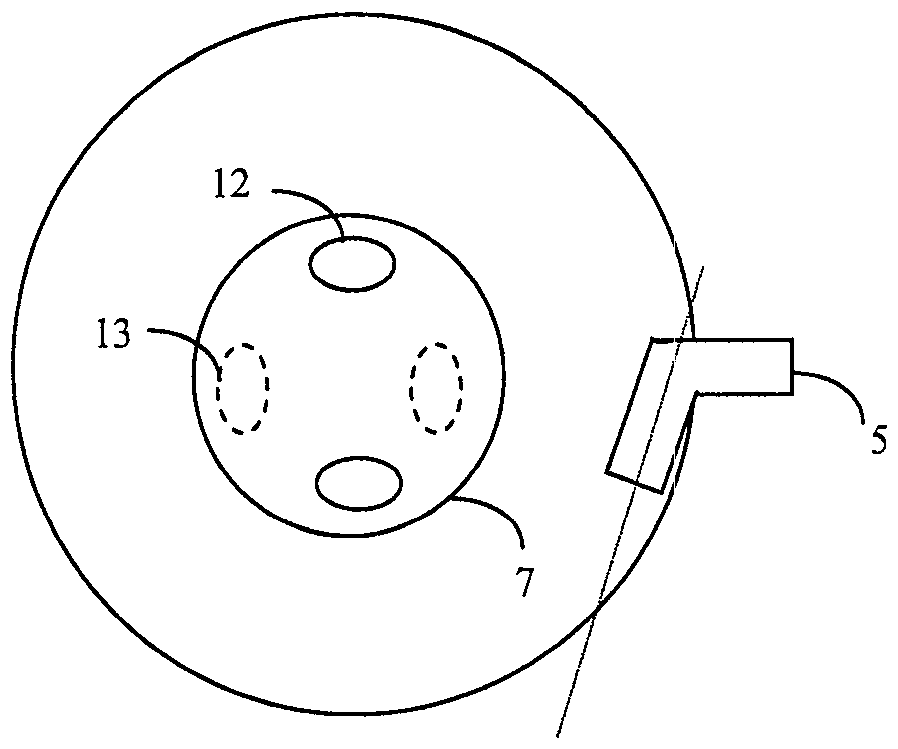

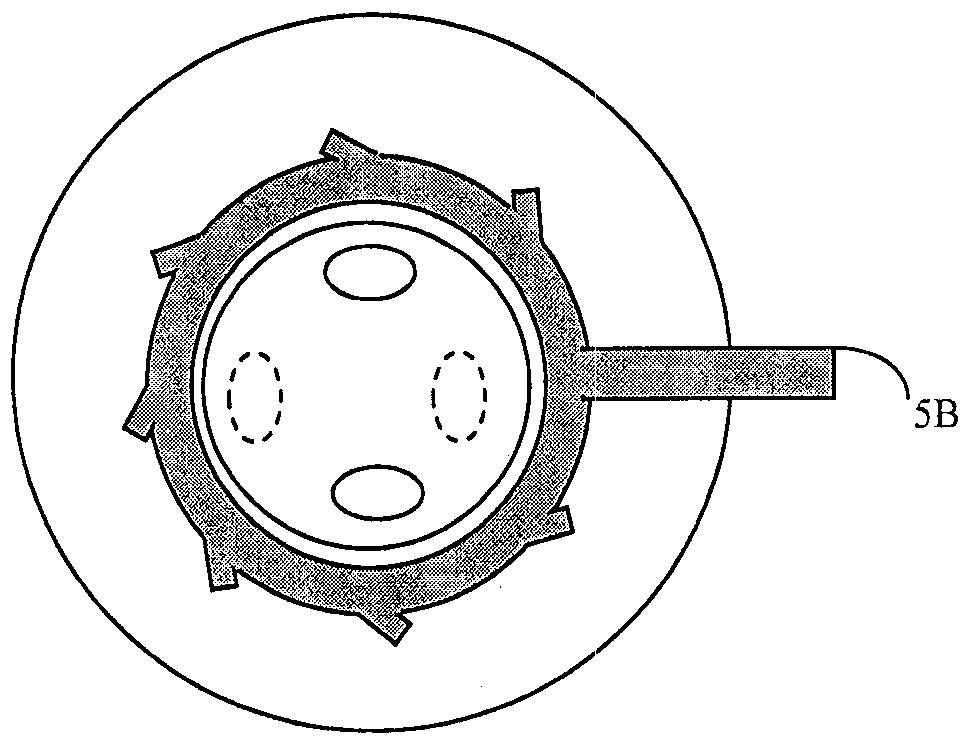

[0028] figure 1 A portion of a reactor in which a hydrotreating reaction is performed is presented. The reactor consists of a shell 1 comprising at least one bed 2 of solid catalyst. The housing 1 may be in the shape of a cylinder closed at its ends. Generally, the axis of the cylinder is oriented in a vertical direction. For example, the cylinder may have a diameter in the range of 1 meter to 10 meters and a height in the range of 3 meters to 20 meters. The upper part of the reactor is supplied with a reaction fluid consisting of gas and liquid, for example, a feed of liquid hydrocarbons and gaseous hydrogen. The reaction fluid flows in a downward vertical direction in the housing 1 , in particular under the force of gravity. In other words, gas and liquid flow as co-currents from the top to the bottom of the reactor. The reaction between the reactants is catalyzed by a solid catalyst, which may be in the form of extrudates or beads placed between two screens, so that a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com