Centrifugal type partition-net-free material bead separator for media stirring mill

A centrifugal and stirring mill technology, applied in grain processing, etc., can solve the problems of limited discharge space, low discharge efficiency, and reduced grinding efficiency, and achieve unobstructed discharge, large discharge flow, and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

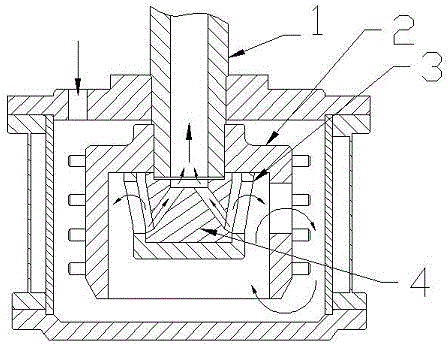

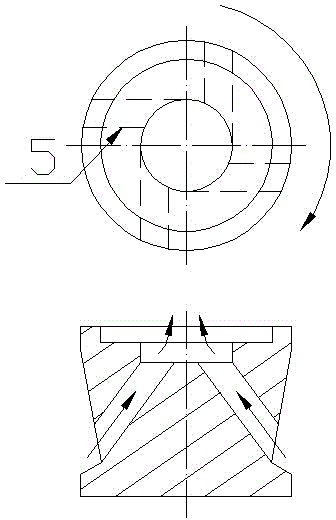

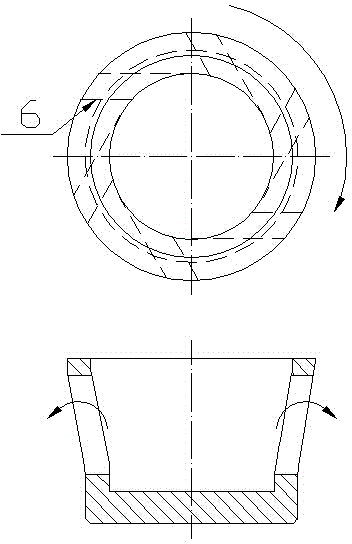

[0015] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings. The centrifugal bead separator without mesh of the present invention comprises: a main shaft (1), a rotor (2), a separation turbine (3), and a discharge shaft head (4). The rotor (2), the separation turbine (3) and the discharge shaft head (4) are all assembled together with the main shaft, which is actually equivalent to three groups of large, medium and small turbines concentrically assembled together. Due to the centrifugal force generated by the turbine The role of the flow field in the axial and radial circulation is formed, and the distribution of the grinding beads in the flow field is farther away from the axis, and the density is higher. The velocity and energy distribution of the flow field shows that the farther away from the axis, the higher the velocity, the higher the energy density, and the greater the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com