Wafer level scribing method for CIS (Cmos image sensor) product

A wafer-level, wafer-level technology, which is applied in the field of semiconductor packaging, can solve the problems of easy chipping of glass sheet cutting edges, large consumption of consumables, and affecting product quality, etc., to improve scribing efficiency, simplify the process, and improve cutting quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

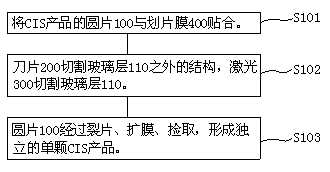

[0072] Embodiment 1, a wafer-level scribing method for a CIS product of the present invention, see Figure 3 to Figure 8 .

[0073] A wafer-level scribing method for a CIS product of the present invention comprises the following process:

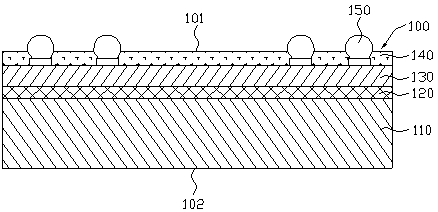

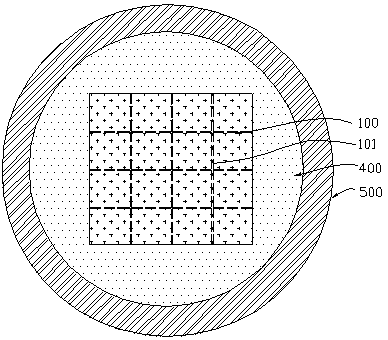

[0074] Step 1. Place the glass layer 110 of the wafer 100 of the CIS product facing down on the film lamination equipment, and the glass layer 110 is bonded to the dicing film 400 on the wafer ring 500 . The wafer ring 500 is used to fix the dicing film 400. The dicing film 400 is a UV film. The UV film has a high viscosity and can be used to stick the wafer 100. The increased viscosity will reduce, so as to facilitate the peeling off of the subsequent wafer 100; as image 3 and Figure 4 shown.

[0075] Step 2. Place the above-mentioned wafer 100 in the dicing equipment. After leveling and aligning, use the blade 200 to cut the silicon base layer 130 and the adhesive layer 120 along the dicing groove I101 of the wafer 100 according to t...

Embodiment 2

[0079] Embodiment 2, a wafer-level scribing method for a CIS product of the present invention, see Figure 9 to Figure 14 .

[0080] A wafer-level scribing method for a CIS product of the present invention comprises the following process:

[0081] Step 1, place the glass layer 110 of the wafer 100 of the CIS product facing upwards and the solder ball layer 150 downward on the film lamination equipment, and the solder ball layer 150 is bonded to the UV scribing film 400 on the wafer ring 500; Figure 9 and Figure 10 shown.

[0082] Step 2. Place the above-mentioned wafer 100 on the laser equipment. After leveling and aligning, cut the glass layer 110 along the scribing groove II 102 of the wafer 100 with the stealth cutting technology of the laser 300 according to the travel program set by the laser 300 ;Such as Figure 11 shown.

[0083] Step 3, use UV light to peel off the dicing film 400 on the solder ball layer 150 completed in step 1 from the solder ball layer 150 of...

Embodiment 3

[0087] Embodiment three, a wafer-level scribing method for CIS products of the present invention, see Figure 15 to Figure 19 .

[0088] A wafer-level scribing method of a CIS product of the present invention comprises the following process:

[0089] Step 1. Place the CIS product wafer 100 with the solder ball layer 150 facing up and the glass layer 110 facing down on the film lamination equipment, and the glass layer 110 is bonded to the dicing film 400 on the wafer ring 500 . The dicing film 400 adopts the UV film of the model Adwill D-821HS produced by Lintec, and its film thickness is 85 microns, which can not only support the wafer 100, but also have a good penetrability to 1064nm laser light. , wherein more than 80% of the laser beam can pass through the UV film, so that the laser can perform stealth cutting on the glass under the scribing film 400 . And common dicing film 400 has more than 90% reflectivity to laser beam, has stopped laser to the cutting action of glas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com